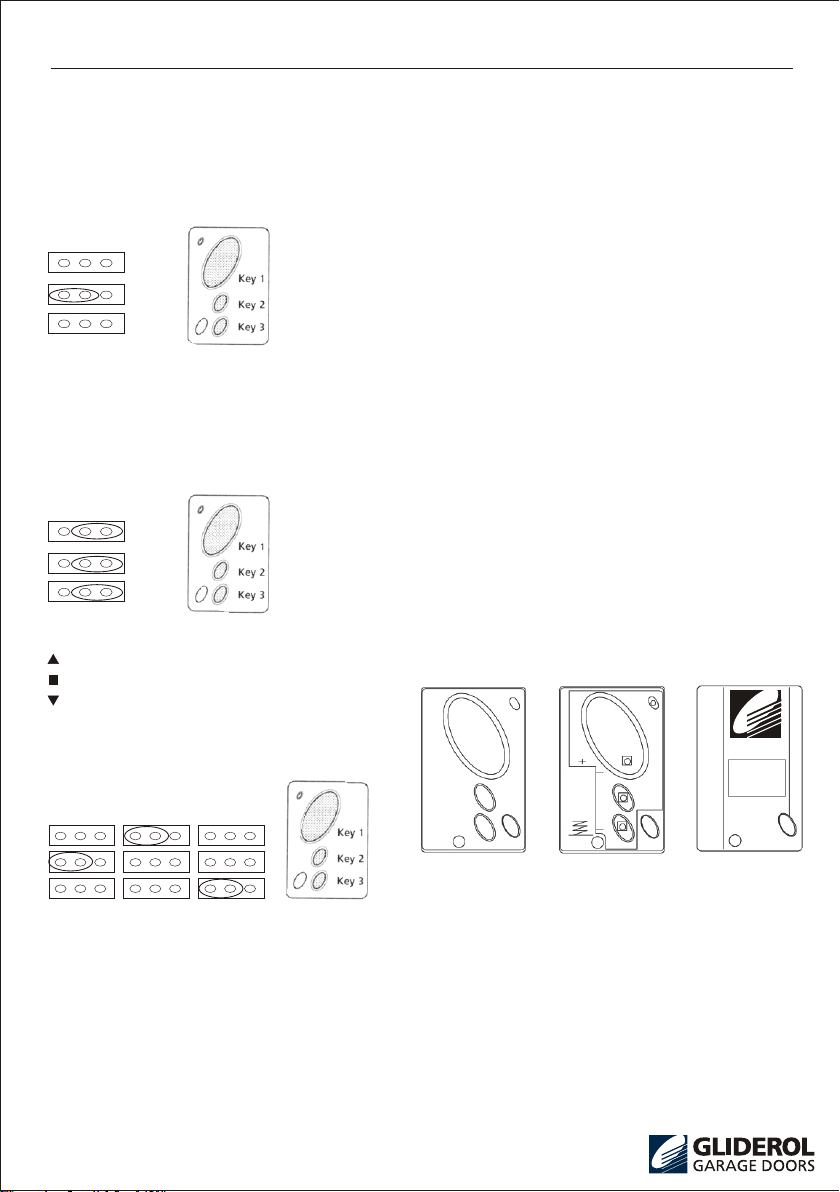

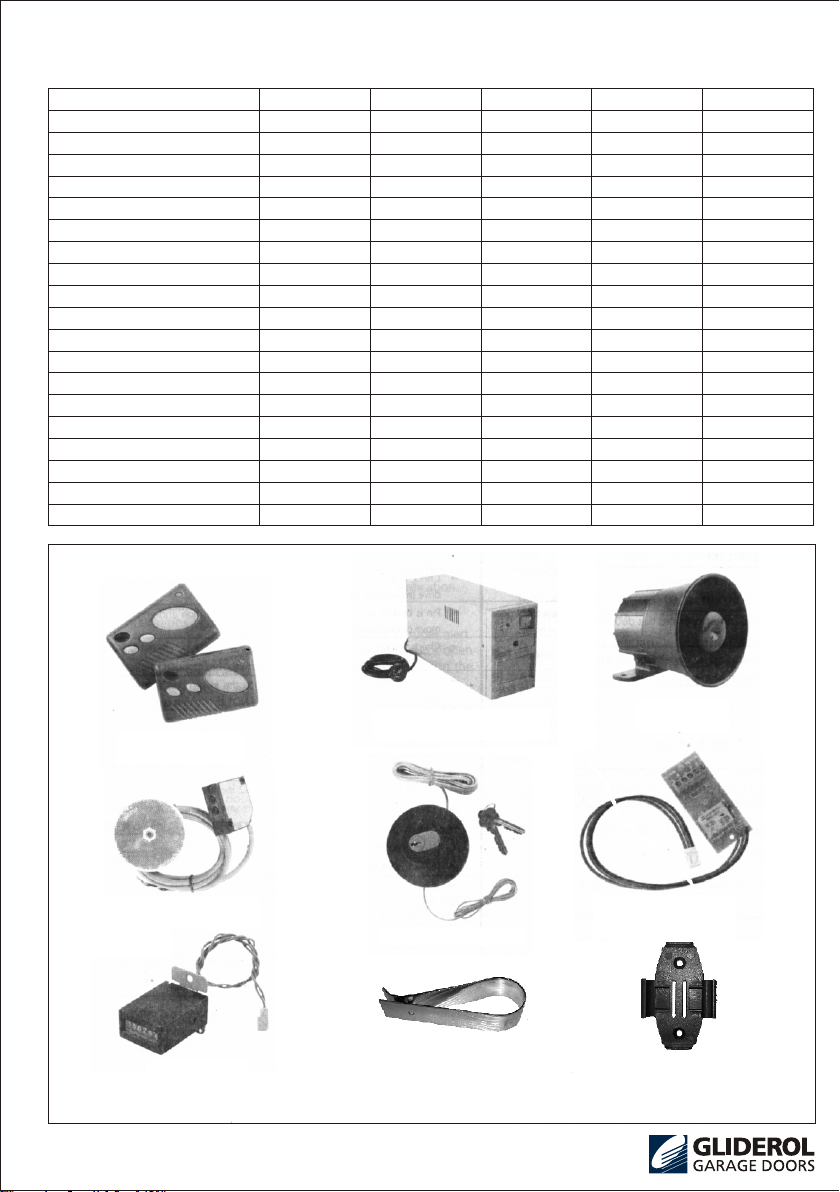

Key Ring Handset

The hand transmitter is manufactured using the latest

surface mount technology and incorporates 3 functional

buttons. This enables the user to remotely control up

to 3 separate operators from the one handset. The soft

touch silicon buttons have been impregnated with a

〝night glow〞 material for easier visibility.

Alarm Closure

If an attempt is made to force open the door from a

closed position, the Glidermatic Controller will pulse

operate the door to the fully closed position.

Remote Switch

A si mple B ell Pr ess typ e m omen tary switch can be

hard wired directly to the control board.

ACCESSORY OPTIONS

With the installation of a small accessory board, the

Gildermatic Controller can perform the following

functions:-

External Light

This a ccessor y o ption wil l allow the c onnecti on of

auxilia ry li ghting, i.e. dri ve wa y lig hti ng, i nter nal

garage lights.

NB: Max. Load 100W

! WARNING

All mains lighting must be fitted by a qualified Ele

ctrician / Personnel

External Counter

For commercial applications an electronic counter (for

door operations) can be used for warranty verification.

Local Alarm

A Piezo Alarm Siren can be fitted as a local intruder

alert. This will be activated if an attempt is made to

force open the door from the fully closed position. In

conjunction the door will perform an Alarm Closure.

This output can also be wired into an existing home

alarm system.

*Alarm closure as above.

External LED Indicator

An LED panel is fitted within the house (hard wired) to

show the status of the door i.e. opened or closed.

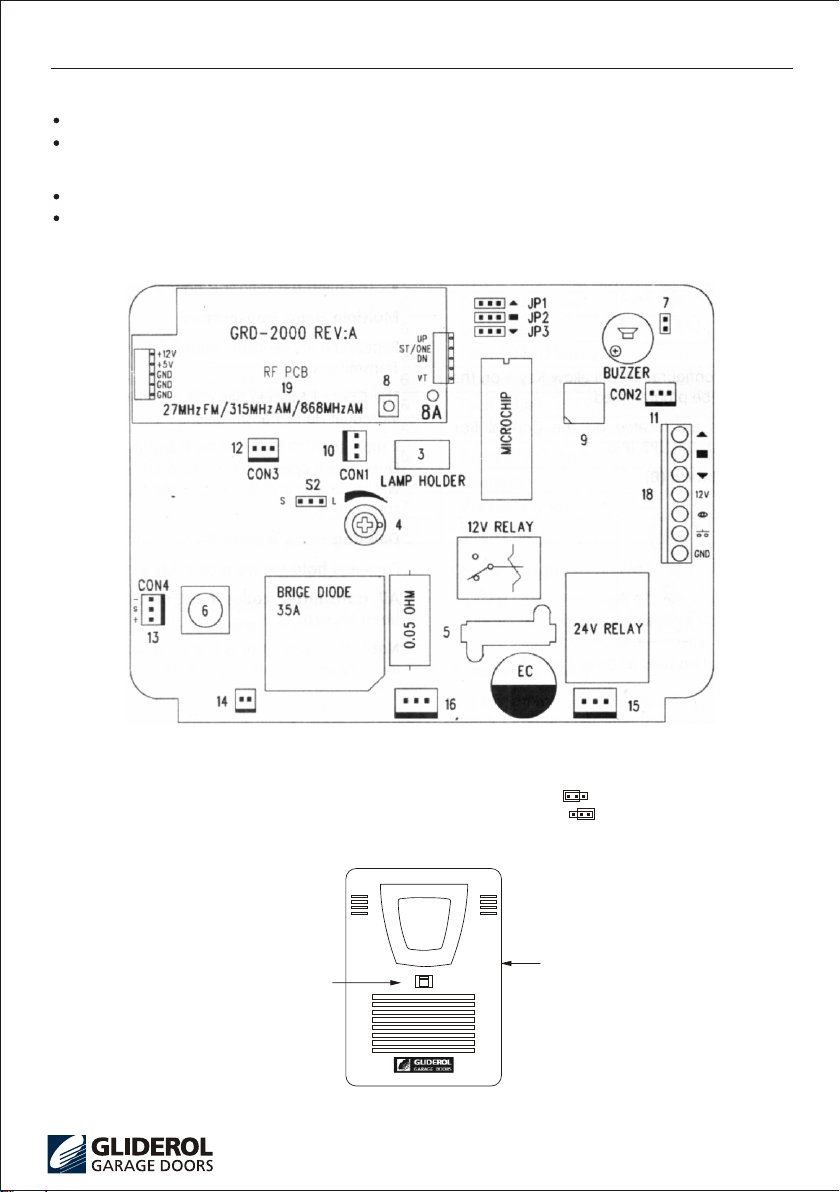

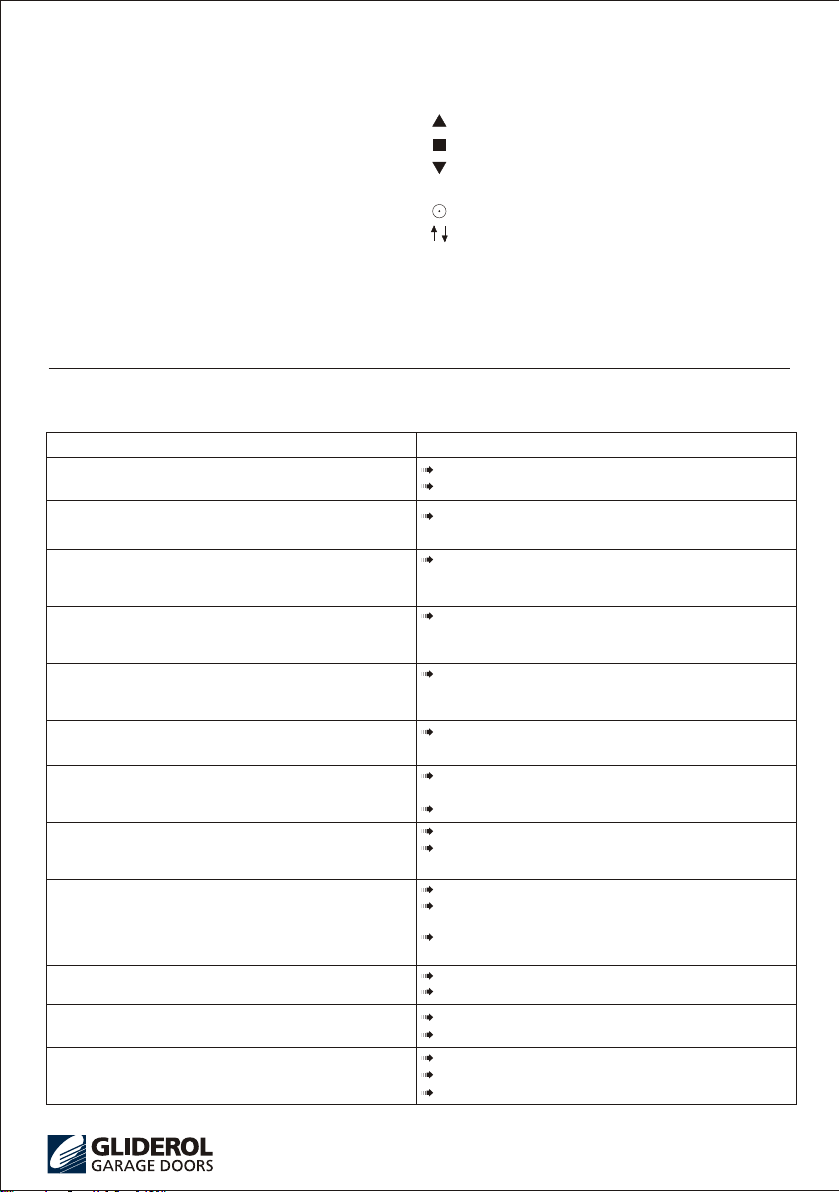

OPERATING CONTROLS (Fig. 9)

1)Control Box Push Button

Pressing this button will open, close, or stop the door.

2)Hand Transmitter

No min al ly fo r a si ng le d oor i ns tal la tion on ly t he

la rge e ll ipt ic al b utt on i s progr ammed t o op era te

th e do or, a m oment ar y pr es s of th is bu tto n w ill

open, close, or stop the door.

Note: The standard Glidermatic handset has three

fully functional and independent buttons. This allows

the hand set to operate up to three opener s,in the

Gliderol series ie Roller Door Opener,(GRD)Tilt and

Sectional Opener,(GTS)and the Commandoor 2 Gate

Opener.

3) Courtesy Lamp

This is a 9-Watt 24VDC Globe which is turned on after

each activation of the Control Box. The illumination

period is approximately 60 seconds.

4) Obstruction Detection (overload)

This adjustment pot allows you to increase or decrease

the amount force required on a moving door to register

an overload condition.

5) Fuse

This is an automotive blade type fuse.

15 A (Blue)

6) Operation Switch (During Set Up Only)

This PCB mounted switch will allow you to operate the

controller whilst the front cover has been removed,

enabling you to complete the set up adjustments and

test the unit.

7) Internal Piezo Buzzer (enable / disable)

The Piezo Buzzer is factory set in the enabled mode. To

disable remove the jumper pin (as shown in diagram 9)

8) Code Learning

This button is used to store and delete transmitter(s)

from the on board memory.

The memory will allow up to a maximum of 10 handsets

to be recorded.

If more than 10 handsets are learnt, the FIFO (First In

First Out) system applies, i.e. first code learnt will be

deleted and replaced by the latest code learnt.

8a) Learn LED Indicator

9) Automatic Close

O Position Auto Close disable.

1 Auto Close enabled 5 sec. delay

2 Auto Close enabled 15 sec. delay

3 Auto Close enabled 20 sec. delay

4 Auto Close enabled 30 sec. delay

5 Auto Close enabled 40 sec. delay

6 Auto Close enabled 50 sec. delay

7 Auto Close enabled 60 sec. delay

Please Note:

Time delay will start once the door has fully opened.

INTERNAL CONTROLS / CONNECTIONS

GRD OWNERS MANUAL PAGE 7