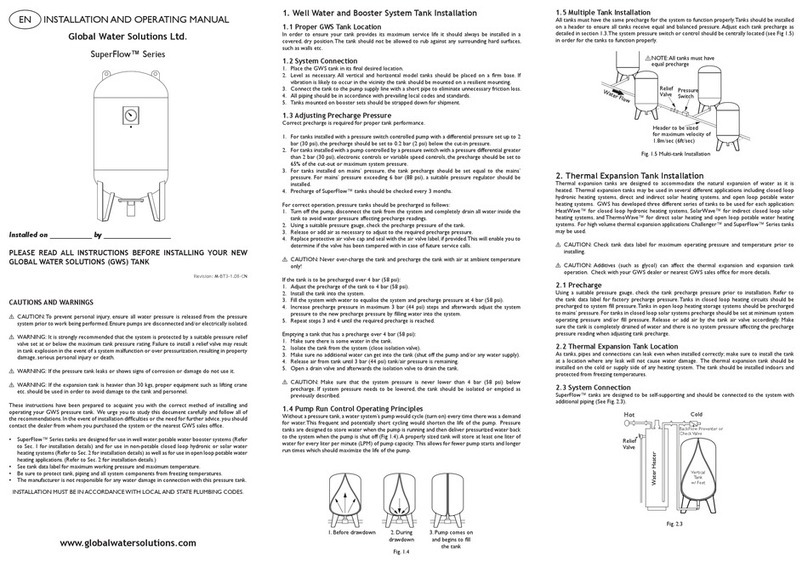

2.4 Solar Heating System

Connections

SuperFlow™ tanks can be used in the solar

liquid loop of indirect thermal transfer systems

and may be mounted either on the suction

or pressure side of the circulation pump.

If a condenser is employed to cool

evaporated solar liquid it must be in the

location between the solar liquid loop and

the expansion tank. A relief valve should

be employed and maximum operating

parameters must not be exceeded. If the

temperature of the solar system has the

potential to rise above the evaporation point

of the solar liquid, a condenser chamber or

coil is required between the solar collector

and the expansion tank (See Fig. 2.4).

2.5 Thermal Expansion Operating Principles

As water is heated it expands. A thermal expansion tank is used to accommodate for this natural

water expansion, which otherwise may lead to increased system pressure and cause damage to piping,

ttings and other system components. A thermal expansion tank uses a membrane sealed inside

the vessel to create a barrier between water and air chambers. The air chamber acts as a cushion

which compresses as heated water expands.The thermal expansion tank absorbs the expanded water

volume and ensures constant system pressure is maintained. Using a thermal expansion tank also

conserves water and energy. This is accomplished by eliminating the need to rell and reheat water

lost due to venting from the relief valve during heating cycles.

3. Maintenance

SuperFlow™ pressure tanks should be checked by an authorized service professional,every 3 months.

To check precharge, shut off power to the pump, isolate and drain the tank. Check precharge using a

pressure gauge. If needed, top up air to appropriate precharge level using an air pump or compressor.

Open isolation gate valve allowing the pump to ll the tank with water.

Always release all water and air from tank before disassembling the parts exposed to pressure such

as anges, air valve, pressure gauge etc. Make sure that the system is switched off and no electricity

or electrical devices are running.

If the pump short cycles or the heating system relief valve constantly opens, check the air valve

mounted on the tank. If water bleeds from the valve the membrane has burst. Please call an authorized

service provider to replace the membrane with a factory replacement, following the instructions for

membrane replacement in this manual.

Check the quality of the water by draining water from the tank using the drain valve. If the water is

rusted, calcied, or has solid deposits, then either the membrane has failed which can be veried by

above mentioned process or the tank is blocked.

4. Membrane Replacement Instructions

1. Turn off the water and/or disconnect the power to the pump.

2. Release the air and drain all water from tank.

3. Unbolt and remove the ange (water connection) from the tank.

4. Remove the nut and the washer on the top of the tank which is attached to the membrane hanger

that is anchoring the top of the membrane (g. 4.1, g. 4.4).

5. Pull and remove the membrane through the bottom opening to which the ange was attached.

6. Remove the top connection membrane hanger from the damaged membrane, this can be reused

and should be cleaned.

7. Take the membrane hanger and attach it to a rod, a cable or alike, as seen in g. 4.2.

8. Pull the rod and hanger up through the membrane until the top of the hanger is protruding from

the top of the membrane (g. 4.3).

9. Feed the rod from the bottom of the tank up through the opening at the top of the tank until the

hanger is protruding from the top of the tank and the threads are visible.

10. Slip the washer and then the hanger nut over the end of the rod/cable and tighten onto the

exposed connector (g. 4.4).

Hot

Cold

Pump

Pump

Solar Collector

Condenser

Solar

Tank

Storage

Tank

Heat

Exchanger

Fig. 2.4

Fig. 4.2

rod

cable

membrane hanger

Fig. 4.1