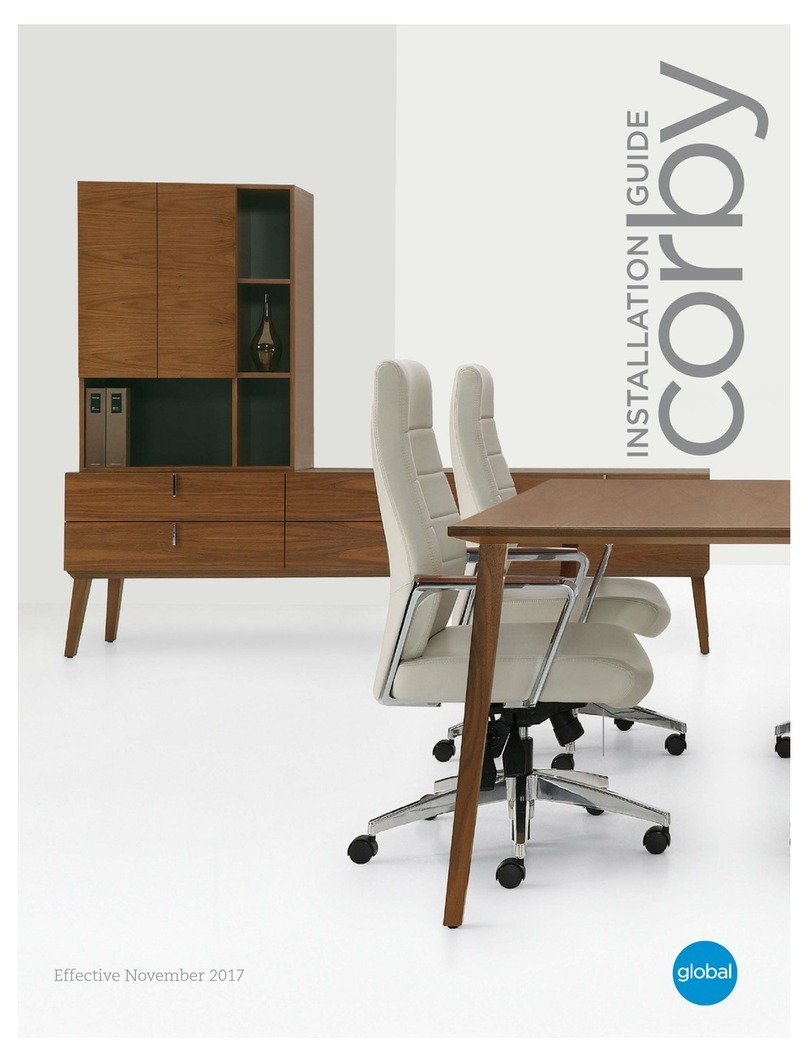

BRIDGES II INSTALLATION GUIDE

2 globalfurnituregroup.com

Beam Applications

Supporting Structure

Legs and Beams

Telescopic Beam

120° Leg

Storage Table Beam

Sliding Return

Round Table Supports

Glide Tray Adapter Assembly

03

04

04

06

07

08

09

10

10

Structure and

Worksurfaces P.03

Dividers

Back-to-Back

Fabric

Fabric - Table Hung

Side-to-Side

Table Mounted

Perpendicular end of run

Modesty panel

Half Height Rectangular Leg Gable

Full Height Rectangular Leg Gable

Table Mounted Divider

Glass Perpendicular End of Run

Glass Side-to-Side

25

23

24

26

27

28

29

30

31

32

33

34

Accessories P.22

Shelves

Elevated + Shared Storage

Hanging Metal Shelf

Table Mounted Center Shelf

Table Mounted End Shelf

Storage Spine

Storage Cabinet Leg Assembly

35

36

37

39

41

42

Storage P.31

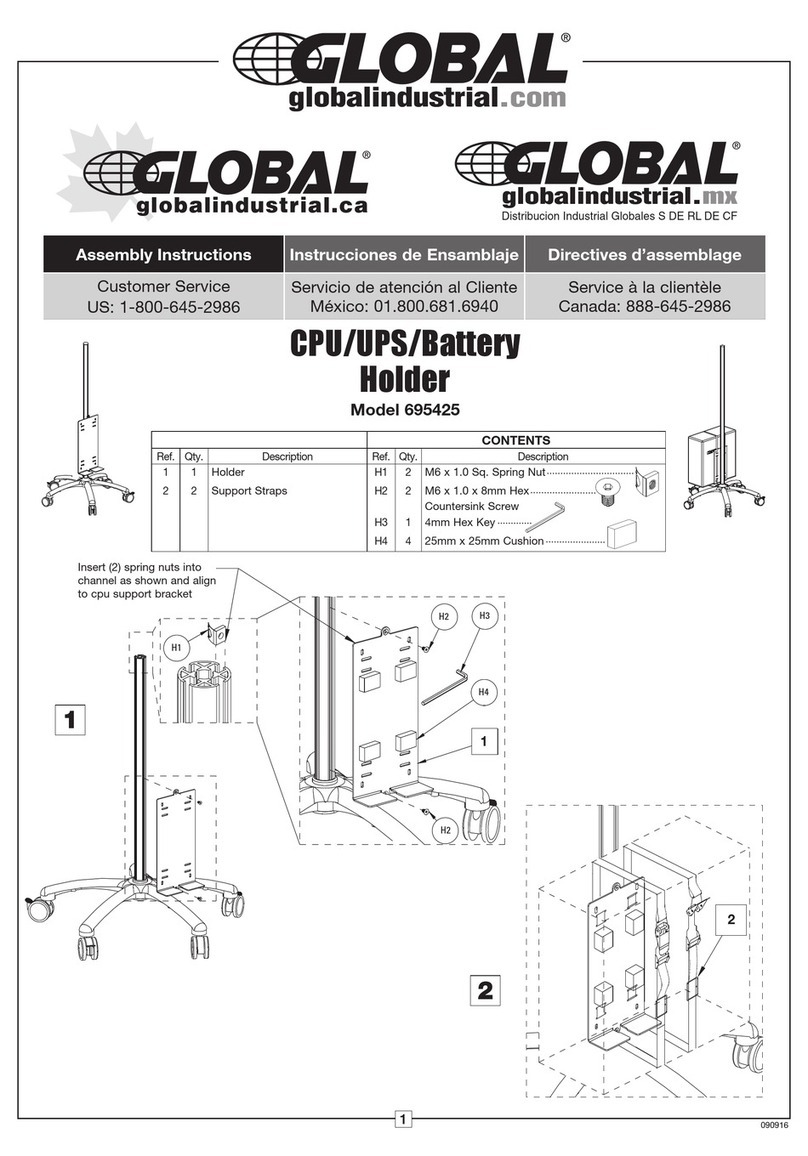

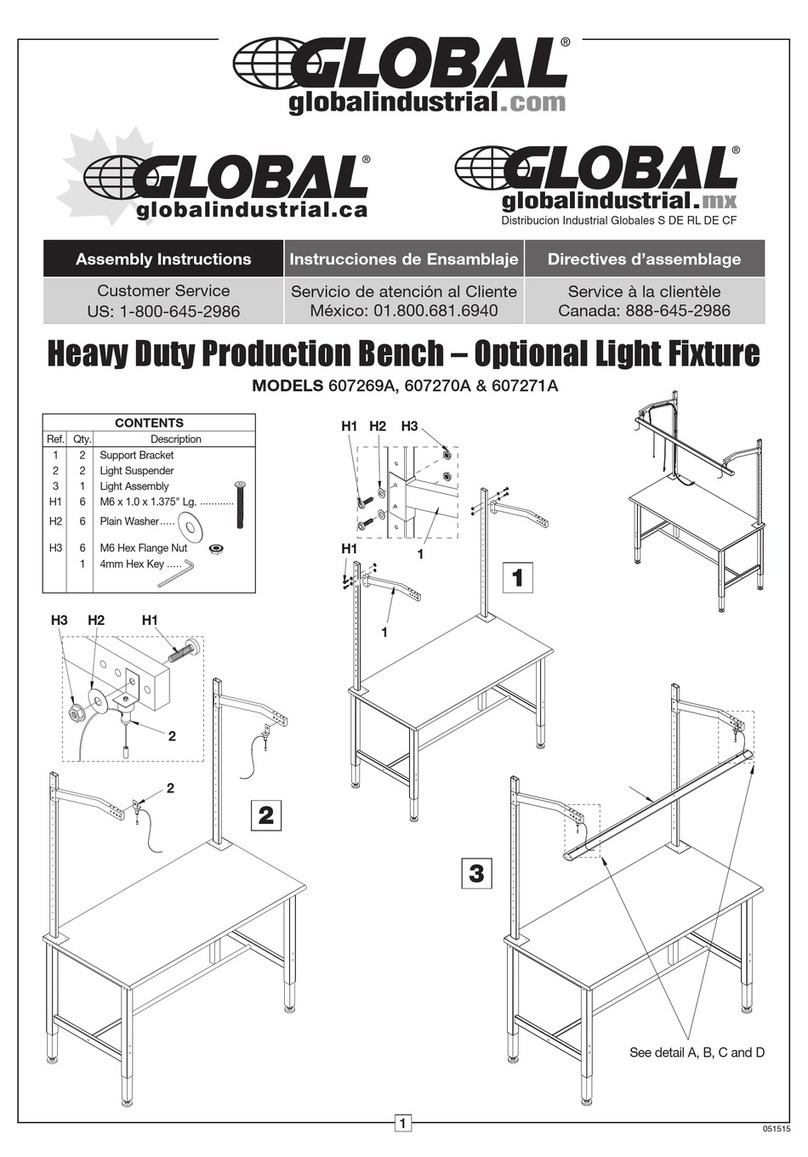

Power Delivery/Cable Management

Wire Basket

Below Worksurface Power Trough

Below Worksurface Power Trough Installation

Power Trough 120° Installation

Power Trough Electric Components

Duplex Retainer Removal

Single Sided Power Trough

Above Worksurface Power Trough

Back-to-Back Storage Tower Gap Filler

34” Leg Shroud

Ceiling Feed

Power Distribution Storage

11

12

12

12

13

14

16

17

18

19

20

21

22

Power, Data and Cable

Management P.11

Bridges II

NOTE: Any alterations to listed components will void the manufacturer’s warranty.

The manufacturer will not be responsible for any damage or bodily harm caused by

alterations in accordance with national or local electrical codes and manufacturer’s

specifications. In accordance with the manufacturer’s policy of continual product

improvement, the product presented in this document is subject to change without notice

or obligation.

Please contact your Global CustomerCare Representative at 800-220-1900 for any questions or concerns.

Bridges II Installation Sequence

NOTE: Although some illustrations depict round legs and some rectangular legs, the leg-to-beam and leg-to-worksur-

face assembly is the same.

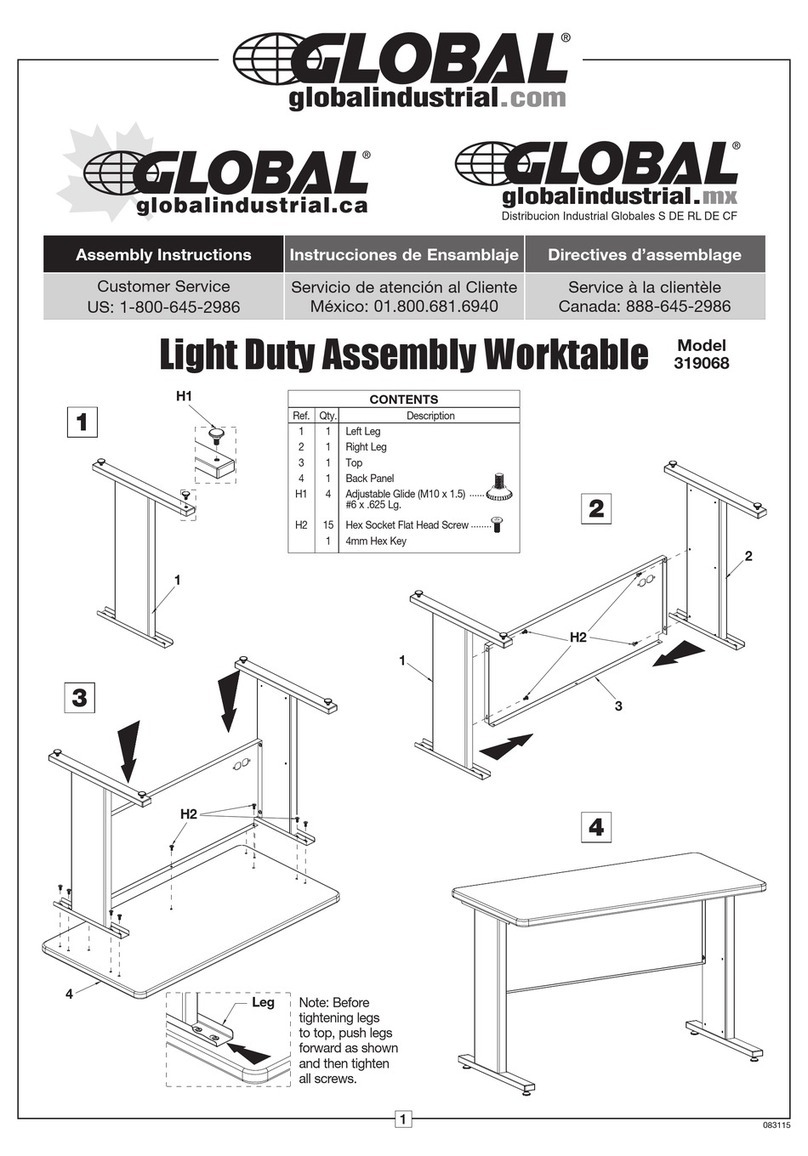

STEP 1: LAYOUT ORIENTATION

Orient the layout plan within the installation area, determine the location of table assemblies, power source and main

storage components; establish the highest point on the floor.

STEP 2: SUPPORTING STRUCTURE - legs, supporting beams

Identify type and size of required components and position them in accordance with layout plans. Proceed with connect-

ing legs and structural beams (see the following pages for detailed instructions). Make sure that all rails are leveled and

securely connected before proceeding with installation of worksurfaces.

STEP 3: WORKSURFACES

STEP 4: ACCESSORIES - task and paper organizers

Determine type and location of accessories as specified in floor plans. Proceed with installation of accessories.

STEP 5: STORAGE

STEP 6: ELECTRICS and DATA / COMMUNICATION - cable routing; cable management

Connect power feed harness to building power supply; check circuit assignments and functionality of power delivery at

each duplex receptacle.

STEP 7: WALK THROUGH / INSTALLATION INSPECTION

43

45

45

46

47

49

50

51

Collaborative Seating P.43

Seat Privacy Partitions

Square Corner Inline Block

Tablet Arm

Ganging Brackets

Connecting to Bridges Tables

Under Worksurface Power Trough

Connecting Display Wall to Bridges Tables

Display Wall Cable Manager TV/Display