Quick Reference WL430-xxx Waste Water Senso

Rev. C

Standard Features:

UL listed

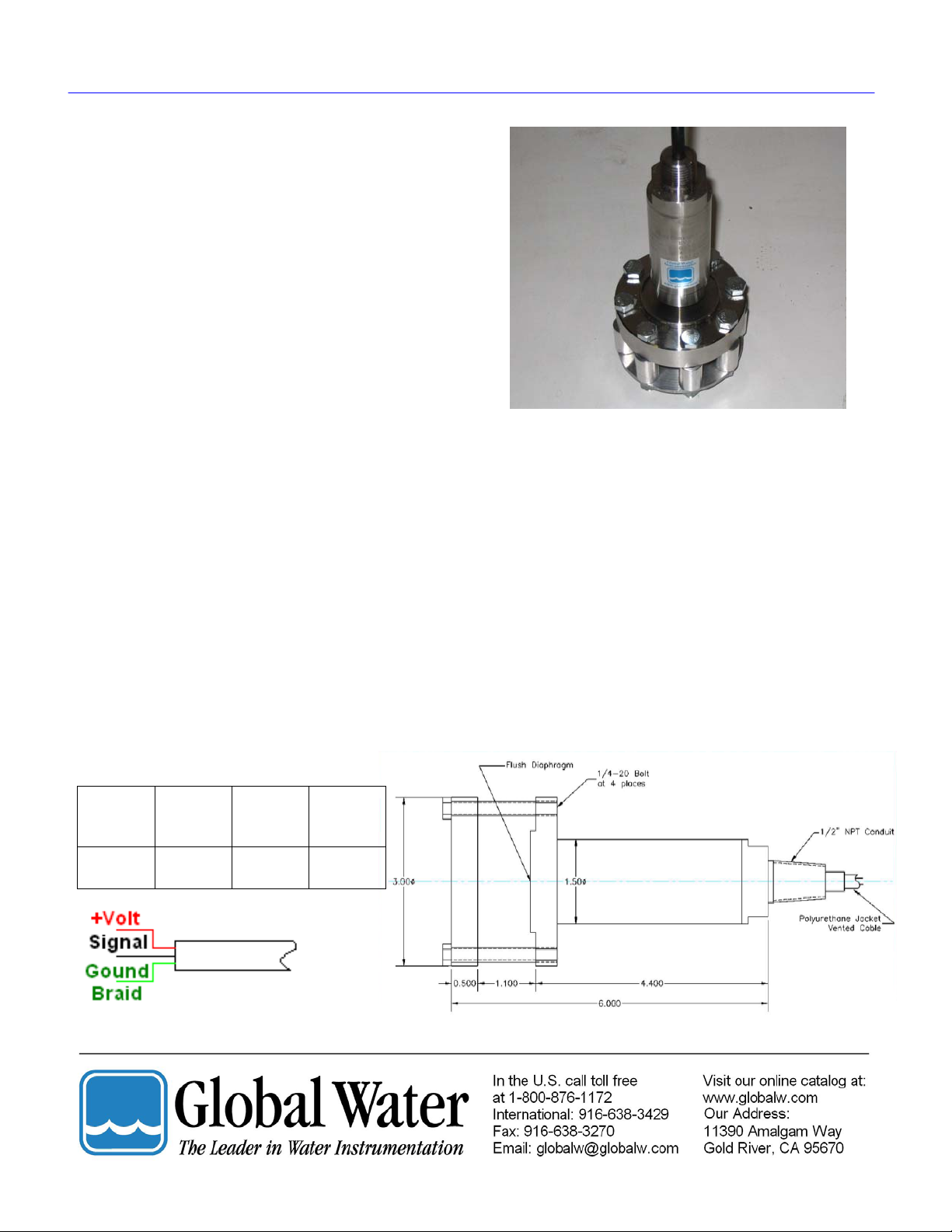

Flush clog-free sensor; 316L SST

Internal protection from lightning and EMI/RFI;

Lifetime Lightning Warranty

± 0.5% FSO Static Accuracy

40 ft. polyurethane cable, vented and shielded

Double-sealed submersible cable exit;

200 lb. tensile strength

TECHNICAL SPECIFICATIONS

PERFORMANCE

Static Accuracy: ± 0.5% FSO ( BFSL, RSS)

(combined effects of non-linearity, hysteresis & repeatability)

Repeatability: ± 0.1% FSO

Temperature Effects: ± 1.5% FSO over comp

range

(combined effects of Zero & FSO with reference at 70ºF)

Long Term Stability: ± 0.25% FSO per year

MECHANICAL

Pressure Range: 0-10 psi, 0-15 psi

Proof Pressure: 2x Full Scale

Burst pressure: 5x Full Scale

Materials: 316L SST plus cable

Pressure Port: Flush mount per outline

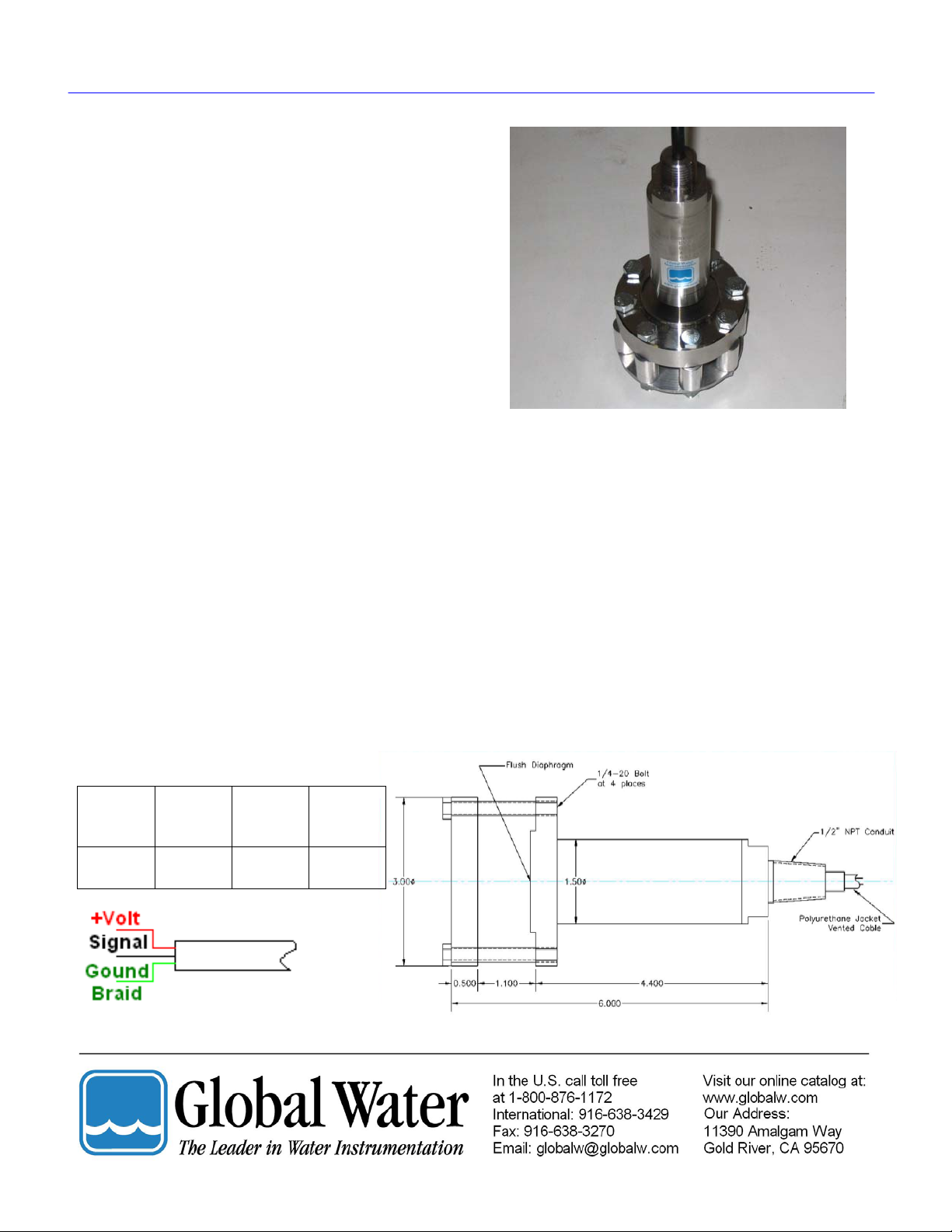

Electrical Connector: 1/2”-NPT Male submersible

conduit fitting with 40ft of polyurethane cable

Dimensions: Per outline

Weight: Nominal 20 oz

Compensated Temp Range: 20 to 170°F

Operating Temp Range: 0 to 200°F

ELECTRICAL

Excitation: 8 - 38 Vdc

Output: 1 - 5 Vdc or 4–20 mAdc

Zero Balance: ± 1% FSO

FSO Setting: ± 1% FSO

Resolution: Infinite ( ±.001% FSO)

Response Time: < 5mS

Insulation Resistance: 1000 MO @ 50 Vdc

Reverse Polarity: Protected

Warm-Up: < 10 mS

Power Supply Effect: ± .002% FSO per V input

EMI/RFI: Internal Filtering

Lightning Protected: MOV and dual gas discharge

tube

Life Lightning protection warranty

Short Circuit Protected: Up to 40 Vdc

Pressure

Psig Level In.

of Water Level Ft.

of water Max.

Pressure

psig

0-10 psi 276.8 23 20 psi

0-15 psi 415.2 34.6 30 psi