5

Issue 002

2. Important Notice

READ THE EQUIPMENT LABELS AND ‘USER INSTRUCTIONS’ BEFORE USING THIS PRODUCT.

BEFORE USING THIS EQUIPMENT IT IS ESSENTIAL THAT USERS ARE FULLY AWARE OF HOW THE EQUIPMENT

OPERATES, WHERE IT SHOULD BE USED, WITH A PREDETERMINED ACTION PLAN FOR BOTH THE USE AND

RECOVERY SHOULD AN EMERGENCY ARISE.

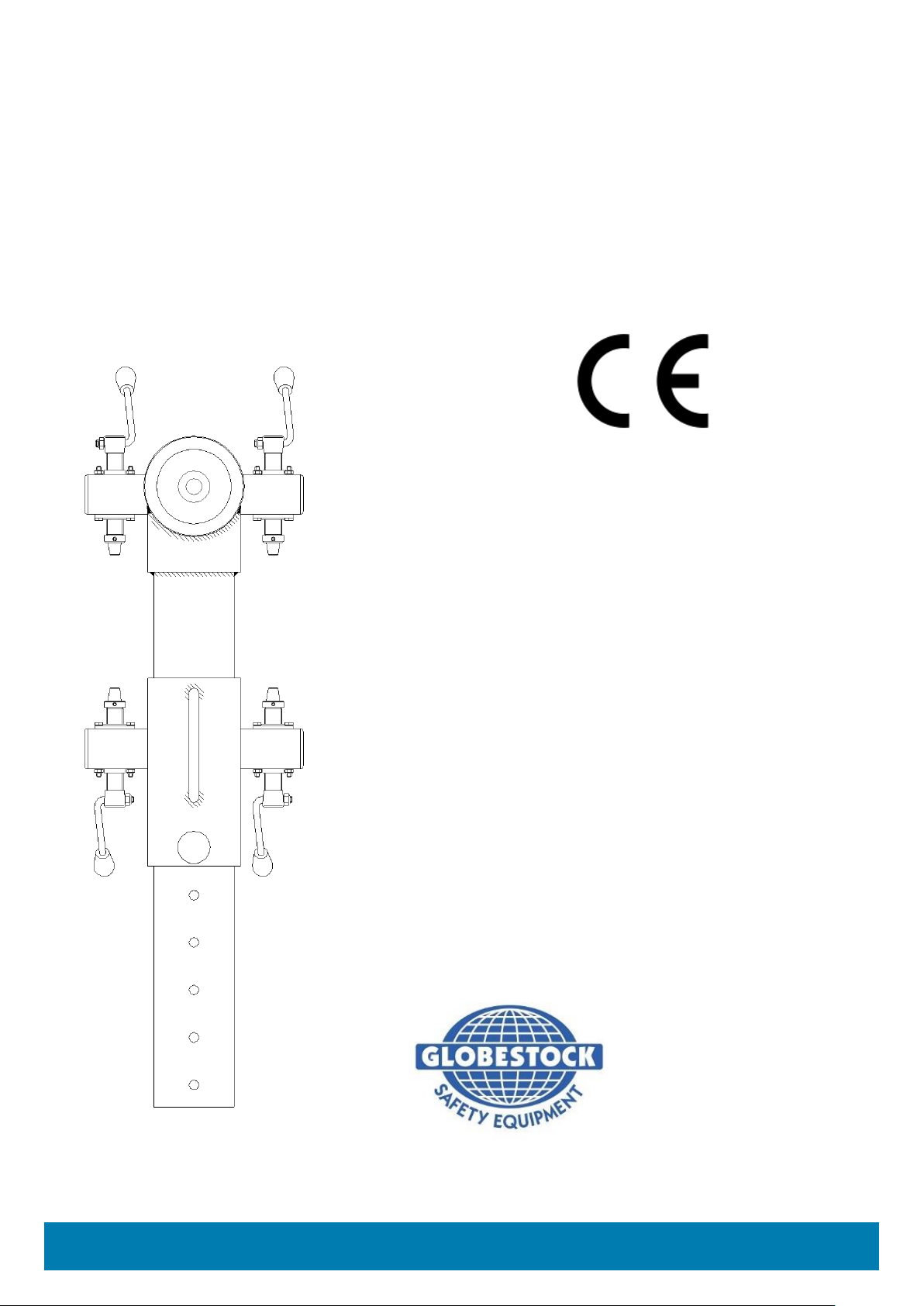

This product has been developed to enable the safe entry/exit of personnel into a confined space or to an

area of restricted access. It is recommended for use in conjunction with the G.Davit, G.Winch for hoisting

personnel and the G.Saver II fall arrest and retrieval device, to protect against falls occurring during use. The

G.Saver II also provides a backup retrieval system for use in an emergency or an unforeseen occurrence. Third

party devices are not recommended.

This equipment is for use where other means of carrying out the work or routes of access are not practical.

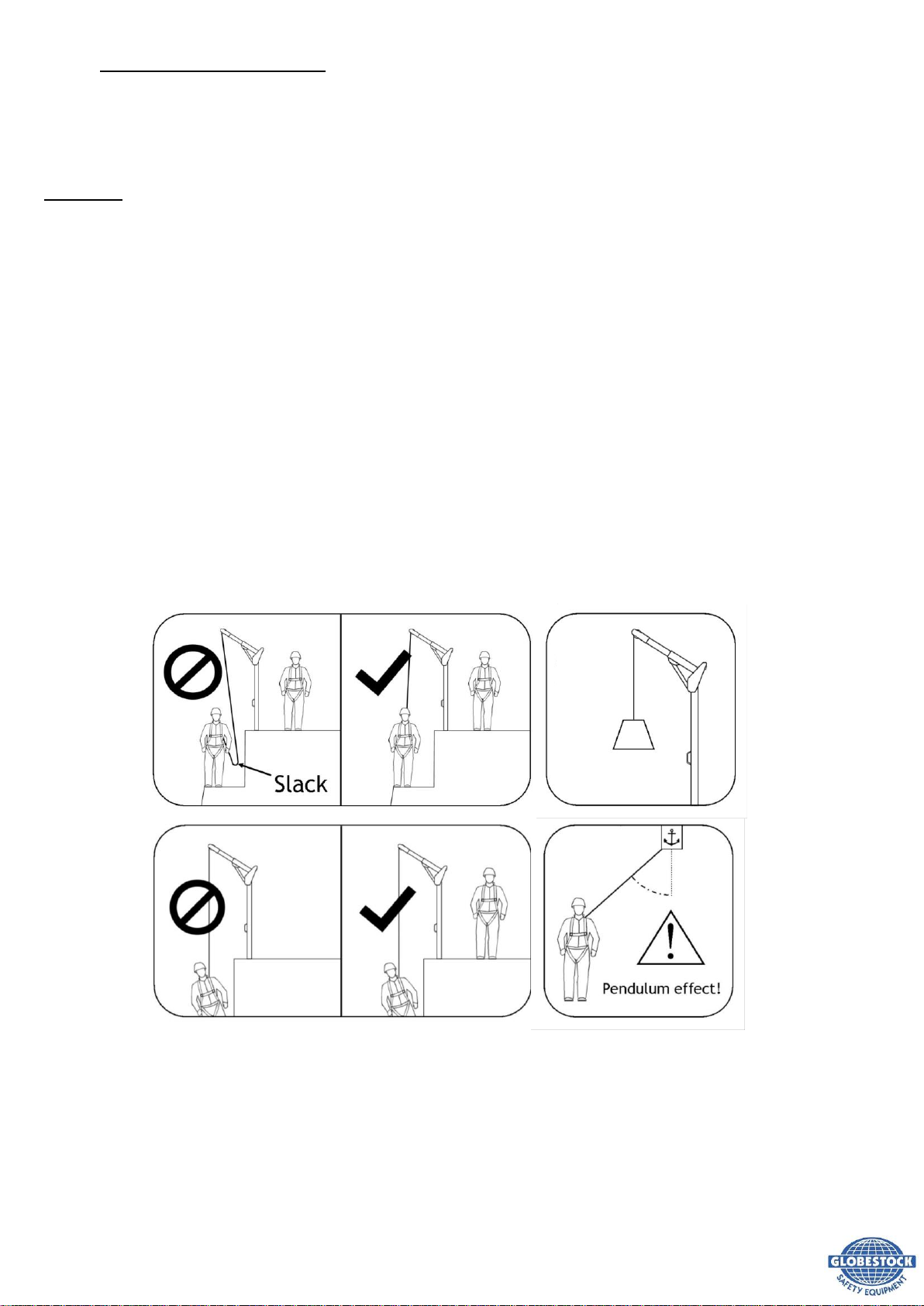

When in use, please observe the Maximum Working Load of the G.Davit and of all associated equipment

being used. The person on the rope end of the davit should never be left to work alone. There must always

be another person present to supervise and operate the G.Davit and the equipment used with it.

Both the person on the rope end of the davit and the equipment operator should be adequately trained and

competent.

This equipment shall not be used outside of its limitations, or for any purpose other than that for which it is

intended.

It is prohibited to make any alterations or additions to this equipment without the prior, written consent of

Globestock Ltd. Any necessary repair will be carried out by Globestock Ltd, or by an authorised Globestock Ltd

service agent, in line with our procedures.

PRIOR TO USE:

A formal ‘Risk Assessment’ should be carried out, considering use and the emergency rescue procedure.

An emergency contingency plan must be in place to rescue the worker in the event of an emergency, before

entering the confined space or area of restricted access to carry out work.

Users should be fully conversant with the operation of the equipment.

The ‘Before Use Checks’ should be performed (see section 4 – Inspection Before Use).

For all equipment being used, verify that the maximum working load is not exceeded.