6

Installation/Operation & Maintenance Manual

GM - 6150H 2-POST LIFT

Chapter 3 SAFETY

It is vital to read this chapter of the manual carefully

and from beginning to end as it contains important

information regarding the risks that the operator and

the maintenance fitter may be exposed to in the

eventuality that the lift is used incorrectly.

The following text contains clear explanations

regarding certain situations of risk or danger that

may arise during the operation or maintenance of

the lift, the safety devices installed and the correct

use of such systems, residual risks and operative

procedures to use (general and specific precautions

to eliminate potential hazards).

WARNING

Lift is designed and built to lift vehicles and hold

them in the elevated position in a closed workshop.

All other uses are unauthorized; in particular, the lift

is not suitable for:

◆ Washing and respire work;

◆ Creating raised platforms or lifting personnel;

◆ Use as a makeshift press for crushing purpose;

◆ Use as goods lift

◆ Use as a jack for lifting vehicles or changing

wheels.

THE MANUFACTURE DISCLAIMS ALL LIABILITY

FOR INJURY TO PERSONS OR DAMAGE TO

VEHICLES AND OTHER PCABLERTY CAUSED

BY THE INCORRECT AND UNAUTHORISED USE

OF THE LIFT.

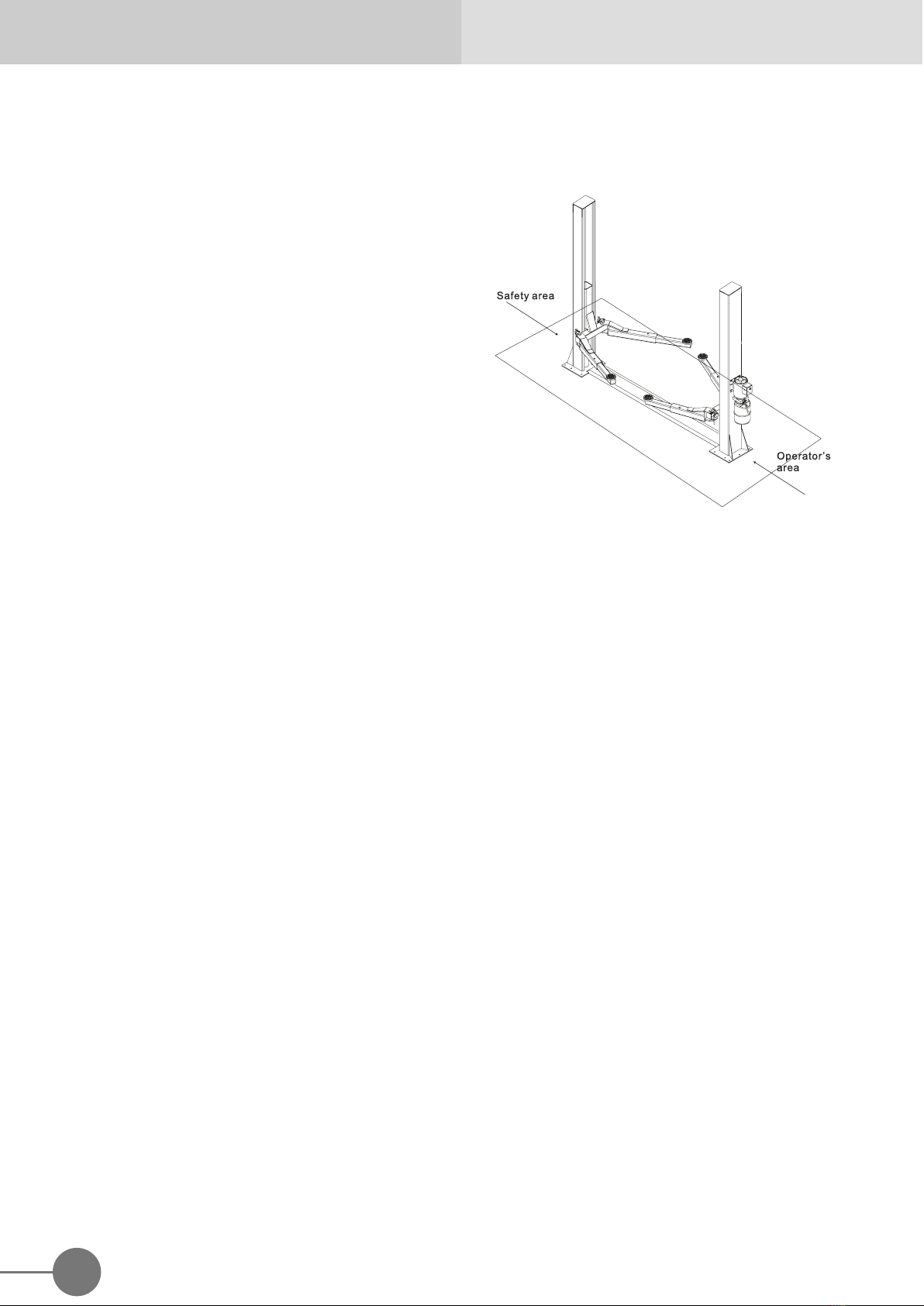

During lift and descent movements, the operator

must remain in the command station as defined in

figure 8. The presence of persons inside the danger

zone indicated in the same figure is strictly

prohibited. The presence of persons beneath the

vehicle during operations is permitted only when the

vehicle is parked in the elevated position.

DO NOT USE THE LIFT WITHOUT PROTECTION

DEVICES OR WITH THE PROTECTION DEVICES

INHIBITED. FAILURE TO COMPLY WITH THESE

REGULATIONS CAN CAUSE SERIOUS INJURY

TO PERSONS, AND IRREPERABLE DAMAGE TO

THE LIFT AND THE VEHICLE BEING LIFTED.

Fig. 10 Working Area

3.1 GENERAL PRECAUTIONS

The operator and the maintenance fitter are required

to observe the prescriptions of accident prevention

legislation in force in the country of installation of the

lift.

Furthermore, the operator and the maintenance fitter

must:

◆ Always work in the scheduled working area as

shown in the manual;

◆ Never remove or deactivate the guards and

mechanical, electrical, or other types of safety

devices;

◆ Read the safety notices affixed to the machine

and the safety information in this manual.

In the manual all safety notices are shown as

follows:

DANGER: indicates imminent danger that can result

in serious injury or death.

WARNING: indicates situations and/or types of

maneuvers that are unsafe and can cause injuries of

various degrees or death.