GMR maskiner a/s Page 10

STENSBALLE / NESBO sweepers

User manual

GB

Handling and assembly

Noise Sweepers produced by GMR maskiner are extremely quiet. The noise

level depends on the type of tractor and is typically between 74 and

85 dB (A). The noise level is indicated in the tractor’s user manual.

Handling

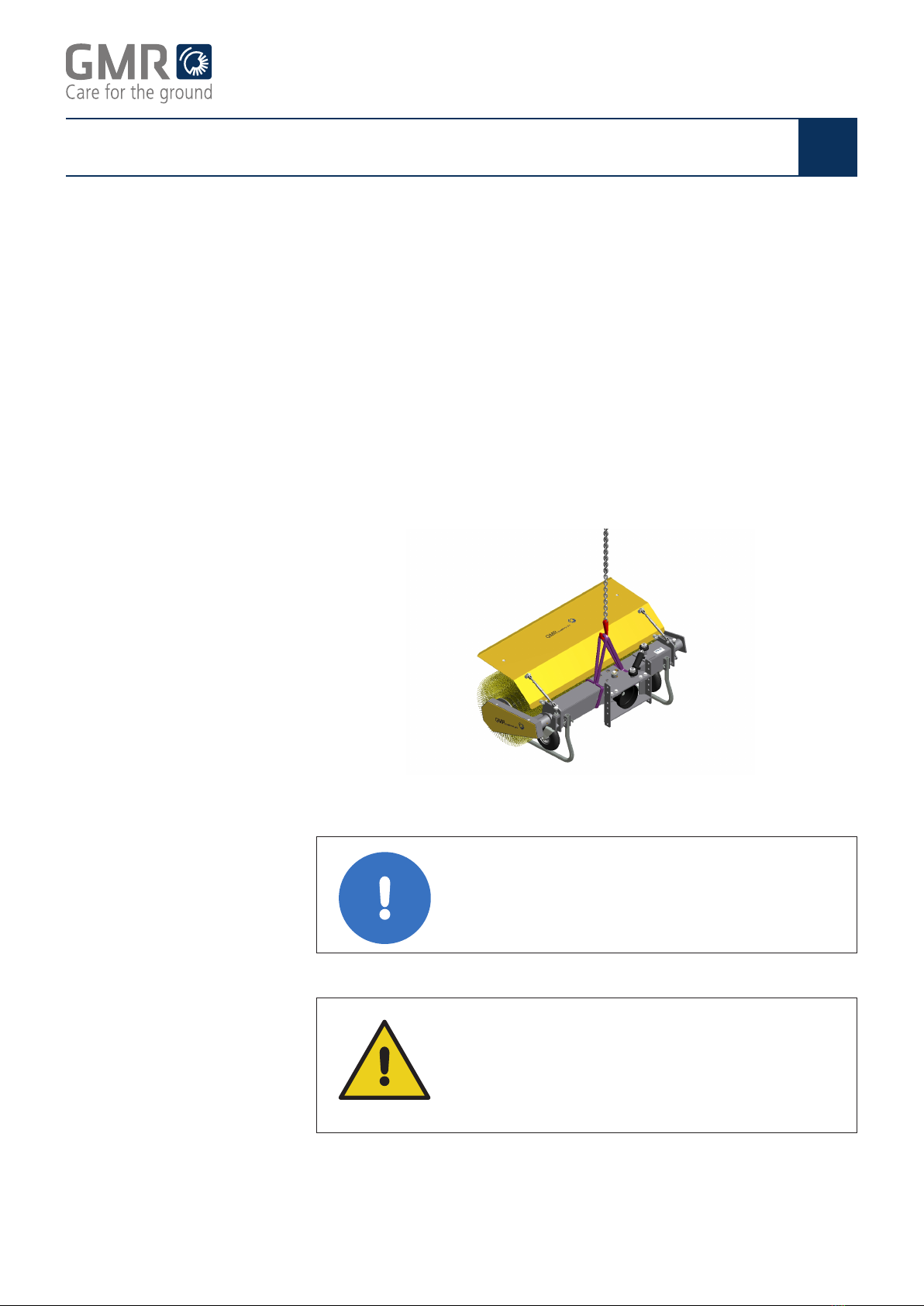

Fig. 1

Hearing protectors If the tractor operator is disturbed by noise, we recommend the use of

hearing protectors or similar.

All sweepers are equipped with 2 support legs. When the support legs

are tted, the sweeper remains in a stable position when disconnected.

Use a crane to move, transport or carry out maintenance.

The crane must always lift in the centre of the main beam.

See Fig. 1.

CAUTION

Risk of damage to brushes/brush rolls

Make sure that the support legs are tted when the

machine is being lifted with the crane.

WARNING

Safety zone

When lifting the machine, everyone must keep a

distance of min. 3 metres from the machine as there

may be unintended movements.

If the machine is lifted by crane for maintenance, the sweeper must be

safely supported before work is carried out under the machine.