To prevent unnecessary breakdowns and excessive wear-and-tear,

your truck should be maintained at regular intervals.

Electric motor NEVER use a high-pressure/steam cleaner to clean the motor as this

can cause condensate to form.

The truck must be serviced twice a year by a GMR-approved

technician.

If the truck does not work properly, read the alarm code and contact an

authorised technician.

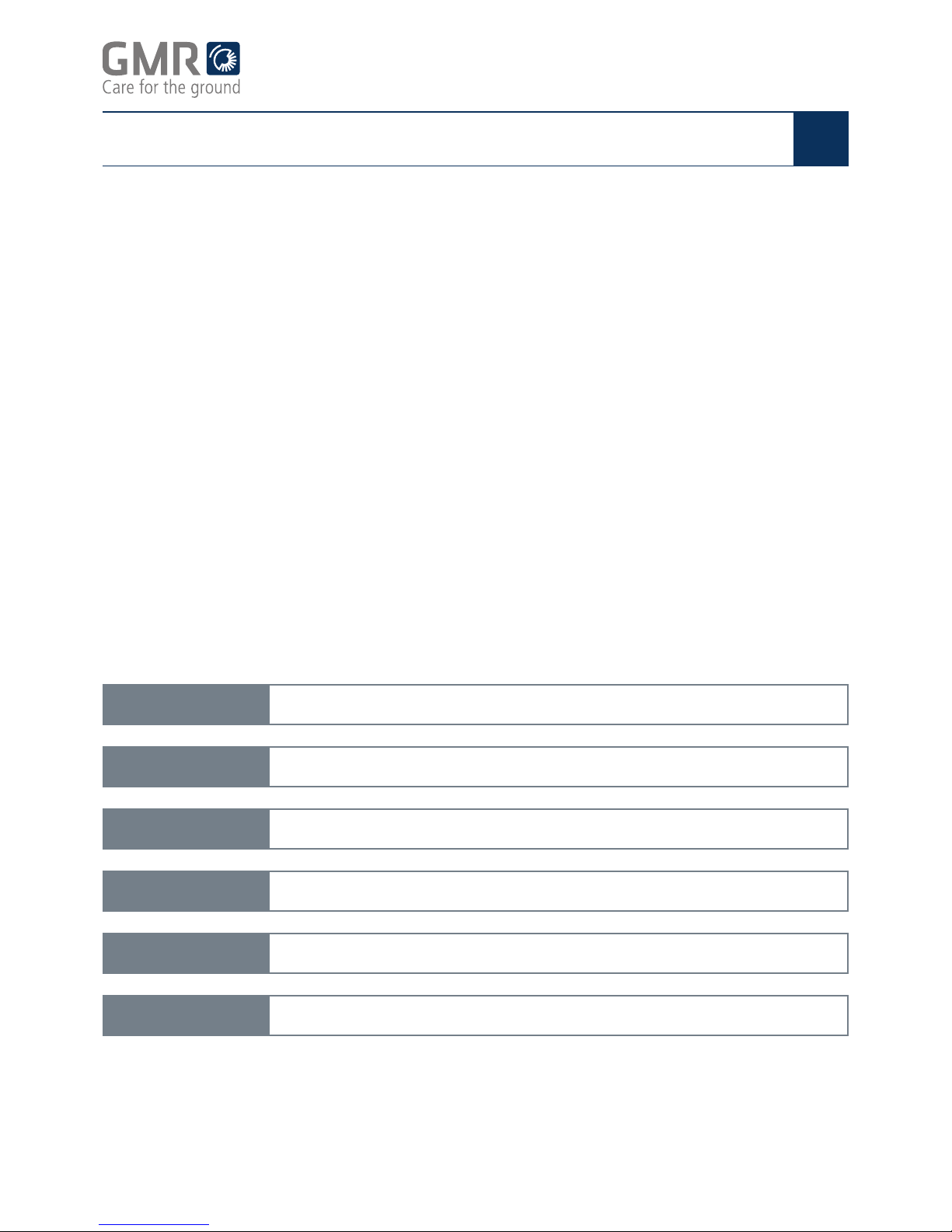

Error code:

14 Main relay does not crank due to pump start

16 / 22 Electronics overheating

28 Operating motors overheating

17 / 23 Battery voltage low

39 Main relay does not crank

47 Error in start sequence, forward/reverse selector switch

and accelerator, seat switch released

To cancel the error, try switching the forward/reverse selector switch to

neutral. Then switch the ignition switch to OFF and restart. If there is an

alarm code in the display all the time, you must contact an authorised

workshop.

For a full list of error codes in English, contact GMR maskiner.

The hydraulic system is generally maintenance-free. However, you

should replace hydraulic uid once a year or after 500 operating hours.

We recommend Shell Tellus Artctic 32 Hydraulic uid.

Hydraulic system

Gear motor

Lubricating mechanical

parts

Grease the ball bearings about six times a year.

Type SAE 80W90 gear oil must be changed after 500 hours of

operation or at least once a year.

Micro, Parker and Mini 0.25 litres

Multi, Evo and Maxi 0.50 litres