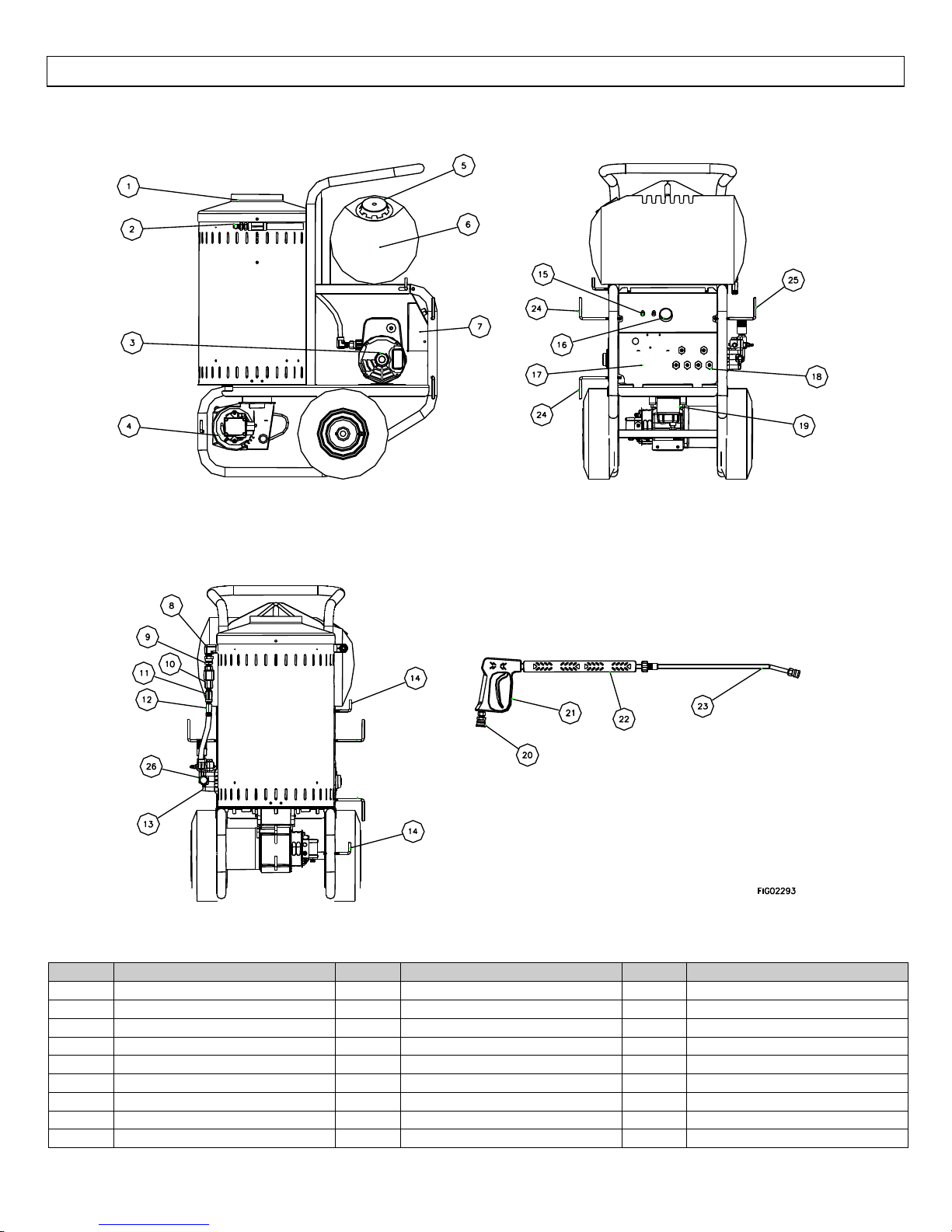

Operating Instructions

Follow these instructions every time you use the pressure washer.

I.) Pre-Operation

A.) Position the machine for easy access to all

controls.

B.) Position the machine on a solid surface, with

less than a three degree slope and so it is

protected from external damage.

C.) Position the machine so that ambient lighting is

sufficient for the surface you are cleaning to be

seen with ease. Use artificial light if needed.

D.) Check hoses, fittings, wand, trigger gun and fuel

connections for signs of wear, cracks and

looseness and replace as required.

E.) Check and clean the nozzle orifice.

F.) Check and clean the water inlet screen and filter.

G.) Read entire manual, especially the important

safety instructions listed on page 2.

H.) Check and maintain proper oil level in the pump.

II.) Check Your Water Supply

A.) Make sure the water supply is clean. Debris can

cause excess pump wear and reduce

performance.

B.) An insufficient water supply will damage your

pump. Make sure the water supply is steady and

is 20% over the rated flow of your pump. Use a

stopwatch to time how long it takes to fill a 5

gallon bucket with your garden hose.

Example: If the rated flow is = 3 gpm

Then required flow = 3 x 1.20 = 3.6 gpm

5 gallons / 3.6 gpm = 1.39 minutes

1.39 min x 60 sec/min = 83 seconds

Therefore, you must be able to fill a

5 gallon bucket in 83 seconds or faster.

C.) The water supply garden hose must have an

inside diameter of at least 5/8”. If the hose is

more than 100 ft. long, the diameter must be at

least 3/4”.

D.) Never use a reservoir tank as a water source.

This pressure washer is designed for a

pressurized water source such as a city water

faucet. Sucking water out of a tank may cause

pump cavitation and damage to your pump.

However, the inlet pressure of the pump must

not exceed 115 psi (8 bar).

E.) Always use a flexible rubber hose for your water

supply. Do not use rigid piping.

F.) Do not pump flammable liquids or liquids

containing incompatible chemicals or solvents.

III.) Before Starting

WARNING: Make sure all switches and controls are

in the OFF position prior to plugging in the cord.

DO NOT stand in water while plugging or unplugging

electrical cord.

WARNING: Use a UL recognized receptacle

protected by a ground fault interrupter and

extension cord of proper voltage and amperage at all

times.

1. Connect electrical cord to specified NEMA receptacle.

See page 4.

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness. Replace as required.

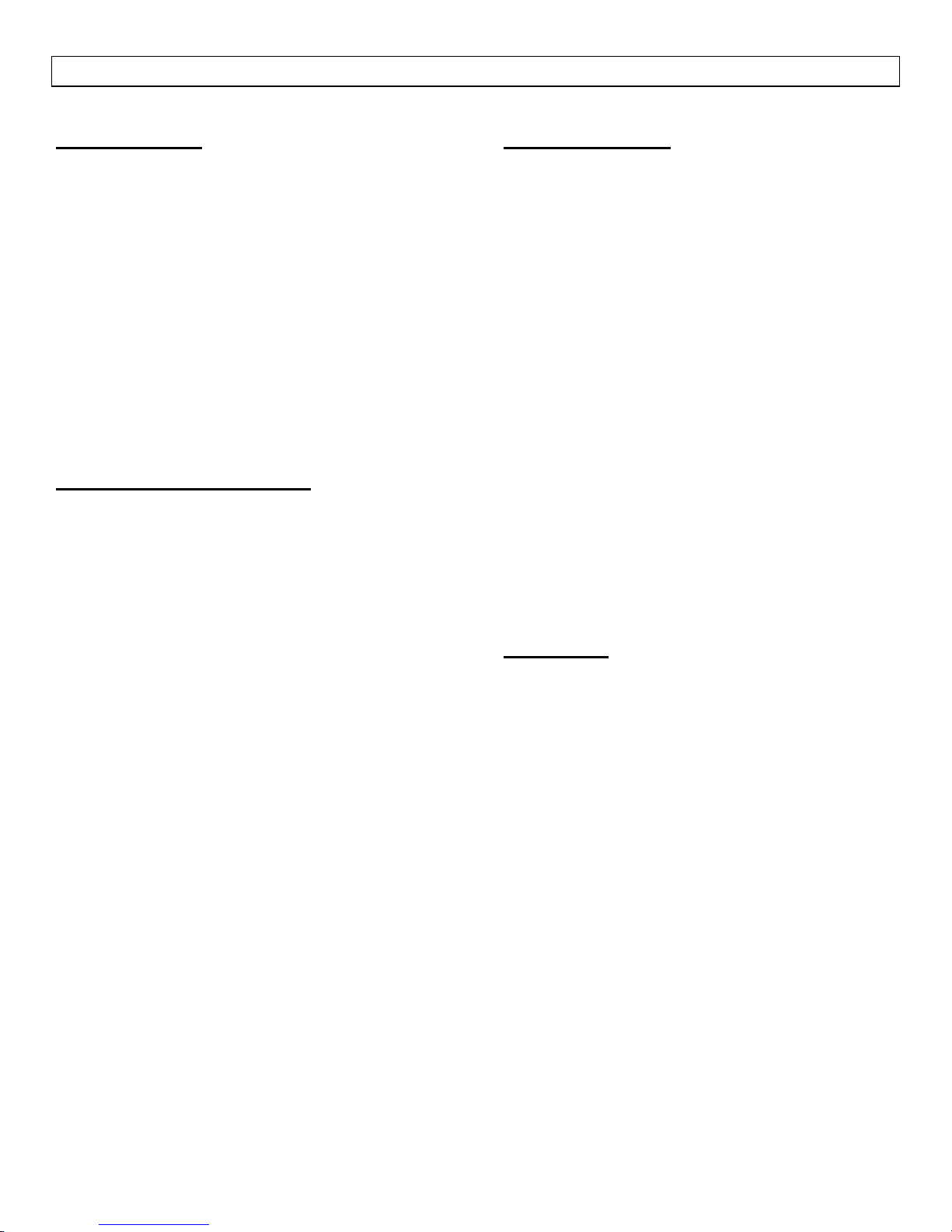

2. Connect water supply hose to the garden hose

connector located on the pump.

3. Fill the burner fuel tank. We recommend kerosene

because it burns cleanest. #1 grade home heating

oil, #1 or #2 diesel can also be used. DO NOT USE

GASOLINE OR CRANKCASE OIL.

4. If detergents will be used, only use detergents

intended for pressure washers. Follow instructions on

the detergent container.

IV.) To Start

DANGER: Do not point the spray wand at yourself or

at any person. Bodily injury may result from water

under high pressure.

WARNING: Wear eye, ear, hand, foot and skin

protection at all times while operating this pressure

washer.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

1. Turn water supply ON.

2. Squeeze the trigger to allow air to purge from the

system. (This step goes faster with the pressure nozzle

removed)