| 8

Table of Contents

1. Tools Required to Install Product........................................................................................................................................10

2. Required Steps Before Installation .....................................................................................................................................10

3. Different Mounting Applications .........................................................................................................................................10

“I” Beam Mounting Fig.2................................................................................................................................................................11

Bottom Chord Angle Iron Mount Fig.3................................................................................................................................11

Top Chord Angle Iron Mount Fig.4.......................................................................................................................................12

“L-Bracket” Mounting Fig.5....................................................................................................................................................................13

“Z-Purlin” Mounting Fig.6..........................................................................................................................................................14

4. Standard Mount .............................................................................................................................................................................15

What is included in the mount package ......................................................................................................................................15

What standard mounts are available Fig.7................................................................................................................................15

How to install the standard mount Fig.8. .....................................................................................................................................15

5. Down Tube ........................................................................................................................................................................................16

What is included in the down tube package ...............................................................................................................................16

How to install the down tube, upper safety cable, and lower yoke assembly.....................................................16

Typical safety cable routing Fig11...................................................................................................................................................16

6. Main Hub and Drive Assembly ................................................................................................................................................ 17

What is included in the main hub and drive assembly Fig.12 ........................................................................................ 17

How to install the assembly Fig 13. ................................................................................................................................................. 17

Installing the lower safety cable (Reference Fig.11 page #11)........................................................................................ 17

7. Guy Wires .......................................................................................................................................................................................... .18

What is included in the guy wires ..................................................................................................................................................... 18

How to install the guy wires:

Fig.14 ...................................................................................................................................................................................................... 18

Fig.15 ...................................................................................................................................................................................................... 18

Fig.16 ...................................................................................................................................................................................................... 18

Fig.17 ....................................................................................................................................................................................................... 19

8. Blade Assembly ............................................................................................................................................................................... 19

What is included with the blades ....................................................................................................................................................................................... 19

How to install the blades Fig.18 ............................................................................................................................................................................................ 19

9. Leveling the fan & Removing the Oil Vent Plug on the Motor................................................................................... .20

Fig.19 ............................................................................................................................................................................................................................................................... .20

Electrical Installation ............................................................................................................................................................................... 21

Safety Precautions ............................................................................................................................................................................................................................ 21

Wire Requirements ........................................................................................................................................................................................................................... 22

Maximum Power Cable Length ........................................................................................................................................................................................... 23

Power Requirements ......................................................................................................................................................................................................................24

Wire Locations & VFD Connections.................................................................................................................................................................................. .25

ESFR Wire Connections......................................................................................................................................................................................................26-27

Wire Connections (Motor). .....................................................................................................................................................................28

Operation Instructions for the VFD (3 phase & 1 phase applications).................................................................29-30

Recommended Maintenance Schedule & Saftey Precautions....... ....................................................................................... 32

Fan Clearances......... .................................................................................................................................................................................. 33

VividAir Annual Performance Plan.....................................................................................................................................................34

VividAir Annual Performance Plan Record. ................................................................................................................................... 35

Warranties and Liabilities ...............................................................................................................................................................43-46

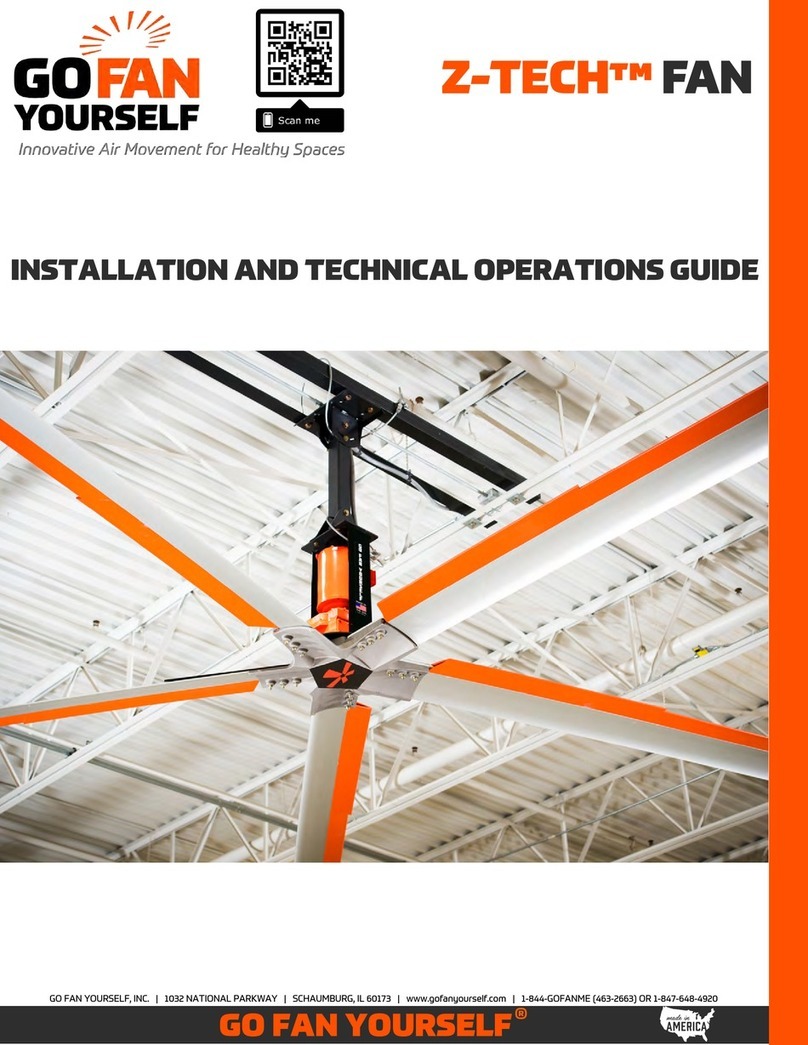

Z-TECH3™ FAN

Installation and Technical Operations

Troubleshooting Guides...................................................................................................................................................................36-42

Locate Your VividAir Fan (Recommended Clearances)................................................................................................9

Fan Operation Best Practices................................................................................................................................................................ 31

VIVIDAIR - ANYTHING ELSE IS STALE Invertek Controller Made In England

Blade Raw Material US or Canadian

ABB Controller Made Overseas - Final Assembly In US