Table of Contents

1. Tools Required to Install Product 10

2. Required Steps Before Installation 11

3. Different Mounting Applications 11

11

11

12

13

14

15

15

15

15

16

16

16

16

17

17

17

17

18

18

18

18

18

19

19

19

19

20

20

21

21

22

23

24

25

26-27

28-28A

29-30

31

32

33

34

35

36-42

43-46

“I” Beam Mounting Fig.2

Bottom Chord Angle Iron Mount Fig.3

Top Chord Angle Iron Mount Fig.4

"L - Bracket" Mounting Fig. 5

"Z - Purlin" Mounting Fig. 6

4. Standard Mount

What is included in the mount package

What standard mounts are available Fig.7

How to install the standard mount Fig.8

5. Down Tube

What is included in the down tube package

How to install the down tube, upper safety cable, and lower yoke assembly

Typical safety cable routing Fig. 11

6. Main Hub and Drive Assembly

What is included in the main hub and drive assembly Fig. 12

How to install the assembly Fig. 13

Installing the lower safety cable (Reference Fig. 11 page #11)

7. Guy Wires

How to install the guy wires:

Fig. 14

Fig. 15

Fig. 16

Fig. 17

8. Blade Assembly

What is included with the blades

How to install the blades Fig. 18

9. Leveling the fan & Removing the Oil Vent Plug on the Motor

Fig.19

10. Electrical Installation

Safety Precautions

Wire Requirements

Maximum Power Cable Length

Power Requirements

Wire Locations & VFD Connections

ESFR Wire Connections

Wire Connections (Motor)

Operation Instructions for the VFD (3 phase & 1 phase applications)

Locate Your GFY

® Fan (Recommended Clearances) 09

Fan Operation Best Practices

Maintenance Schedule / Safety Precautions

Clearance Requirements

GFY Annual Performance Plan

Recommended Maintenance Checklist

Troubleshooting Guides

Warranties and Liabilities

| 8

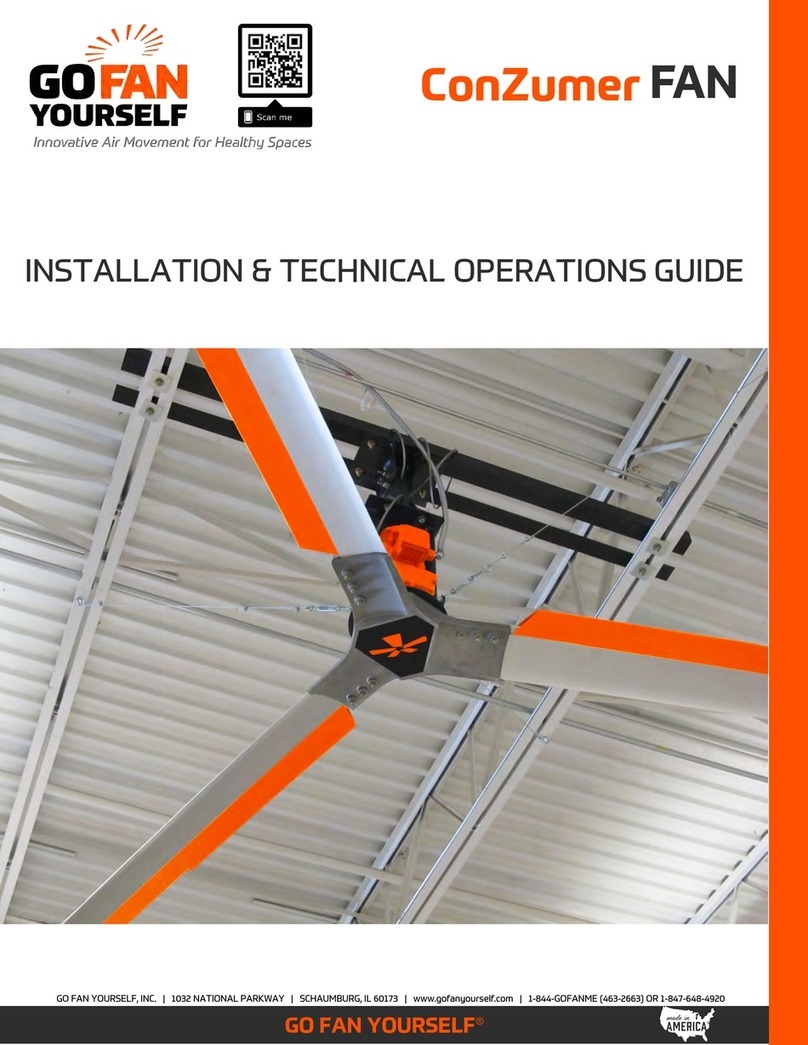

Z-TECH™ FAN

Installation and Technical Operations

®

GO FAN YOURSELF

What is included in the guy wires: