5/8

Have your chimney swept mechanically by a professional sweeper at least twice a year, including once during the heating season.

The sweeper should give you a certificate. It is also possible to maintain the ducts with special products. However, it does not

prevent you from having necessary mechanical sweeping.

Check the appliance condition and make sure the door seals are in good condition, replace them if necessary.

Clean completely the inside of the appliance including the smoke flues.

Clean the glass with GODIN NET product for glass (product code 0009).

In case of a chimney fire, close the air regulator and call firemen.

Have the appliance checked by a competent person at least once a year.

WARNING

AT THE BEGINNING OF USING THE APPLIANCE, IT IS NECESSARY TO MAKE IT RUN IN A MODERATE

WAY, TO ENABLE NORMAL DILATATION OF THE PARTS.

HANDLES ARE HOT WHILE IN USE. USE THE GLOVE (if it is supplied).

THE GLOVE SHOULD BE USED ONLY TO TURN THE HANDLE. IT IS NOT MADE FOR HANDLING BURNING

OBJECTS. IT IS NOT WATERTIGHT. DO NOT USE IT FOR HANDLING CHEMICAL PRODUCTS.

AFTER EACH USE, YOUR GLOVE SHOULD BE PLACED ON A COLD SURFACE WITHOUT ANY

COMBUSTION RESIDUES (ashes).

Do not worry if at the beginning of using the appliance, smoke and acrid smells are emitted, this is due to paints of different parts.

This phenomenon can last a few days.

Maintenance of cast-iron and steel

Any steel or cast-iron stove needs some maintenance after each winter, during the warm season, in order to last a long time. As a

matter of fact, when a stove is in use, there is no possibility for its parts to get oxidised. It is only possible during a long period without

using it.

Cast-iron parts are to be maintained with a black paste (product code 0012). It should be applied cold, then waxed and, when it is dry,

polished with a soft cloth.

Hot temperature spray paint (cast-iron grey, product code 0001) can also be used for neater finish on the outside parts of the stove.

Before applying the paint, make sure that all the oxidation marks have been removed with thin grain emery cloth.

Cast-iron stoves with an enamelled outside finish need their inside firebox to be maintained.

This maintenance is necessary even more in case of appliances installed in houses that are infrequently inhabited.

All our maintenance products are described in our general catalogue (paste, paint, glass cleaning product, sweeping products, etc.).

You may buy them at our retailers.

Specific warning concerning the stove door :

Our doors are hinged upon cone point screws or lock washers.

PLEASE NOTE: In the event that your fitter removes the stove door (to replace the glass, for example), it is important to fit new lock

washers and/or the original cone point screws to the door in question.

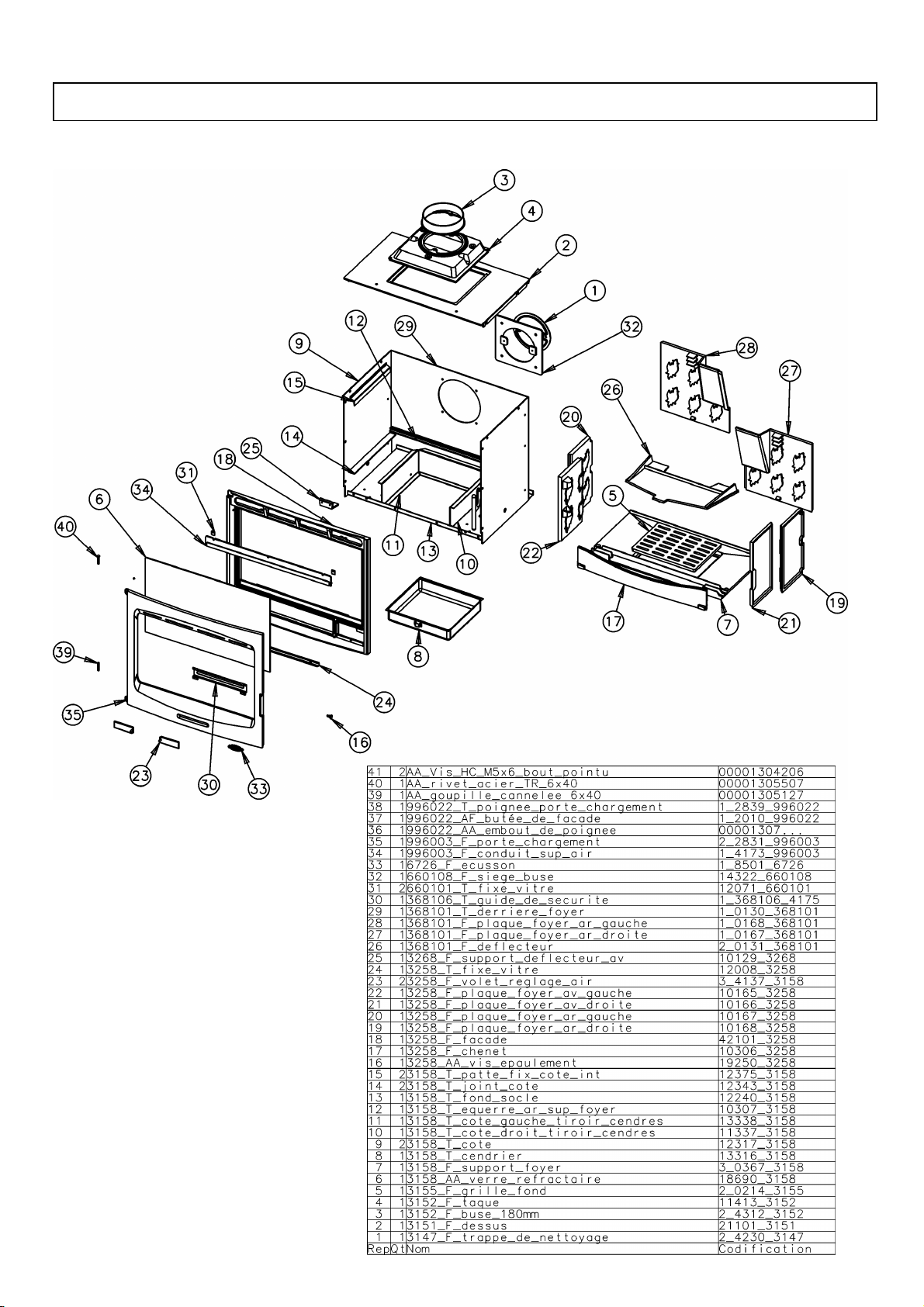

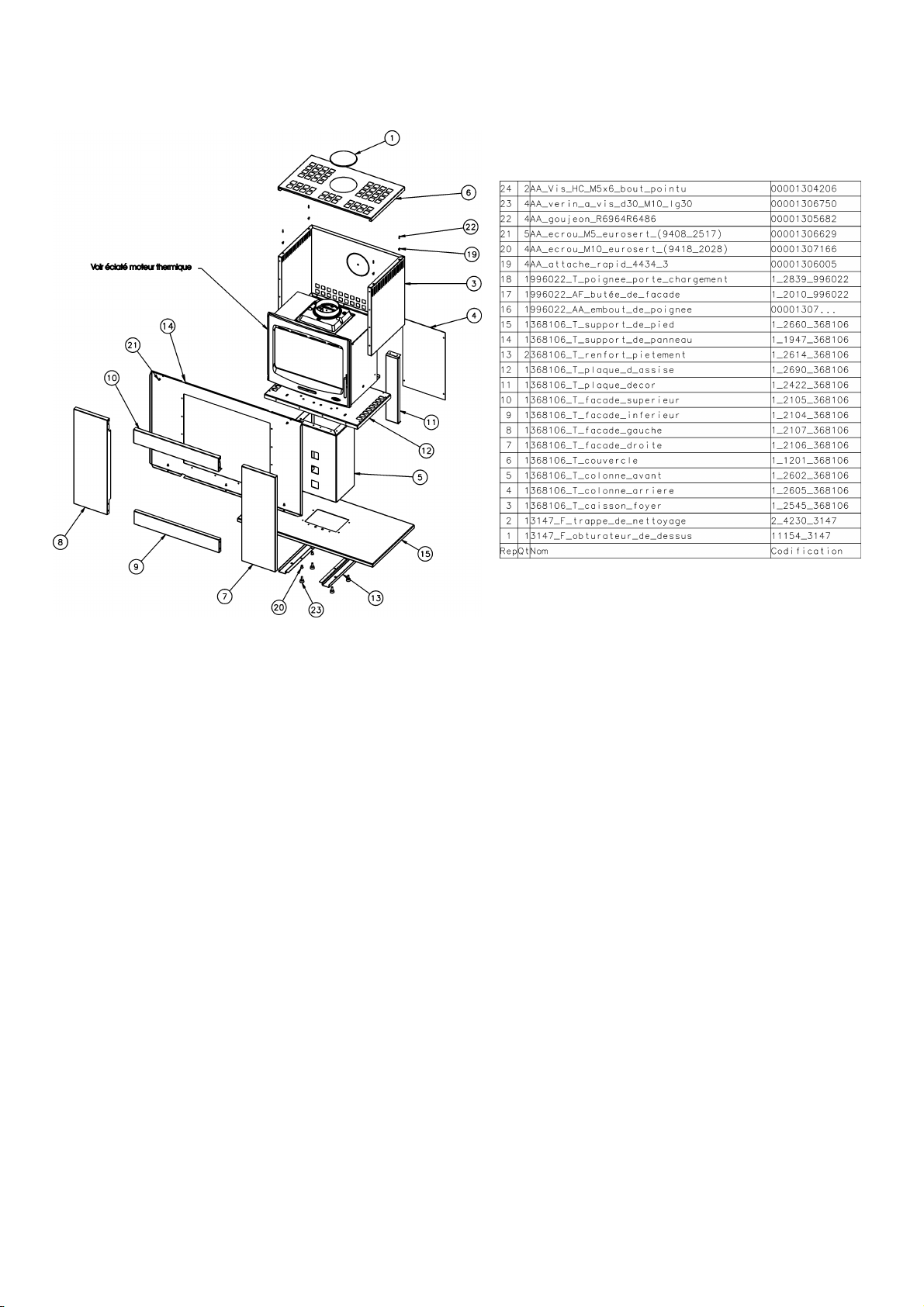

If after a number of years of using your appliance, some parts may need to be replaced, contact your SUPPLIER or any other

PROFESSIONAL AGENT OF OUR TRADEMARK.

You should give him the information written on your INFORMATION PANEL that is situated AT THE BACK OF THE APPLIANCE or in

your GUARANTEE BOND that should be kept even beyond its validity period.

Having all the nomenclature and technical documentation in relation with our products, he will be able to supply quickly any spare part

and carry out necessary repairs.

Never use any spare part that is not supplied by GODIN SA.

Never modify the appliance without prior authorisation.

We remind you that the maker’s liability is limited to the product as it is sold, and that fitting out and

installation service is under the entire responsibility of the fitter who will have to intervene, according to

the rules of good practice and according to the prescription given in the instructions.

In order to constantly improve its products quality, GODIN reserves the right to modify its appliances

without prior notice.