Goldenman Petroleum Equipment Co., Ltd

Warning

XQ140/30 tubing power tong is a kind of high mechanical torque wrench. To ensure safety,

operator should follow the safety information described in this manual.

1.

Safety Information

1.1

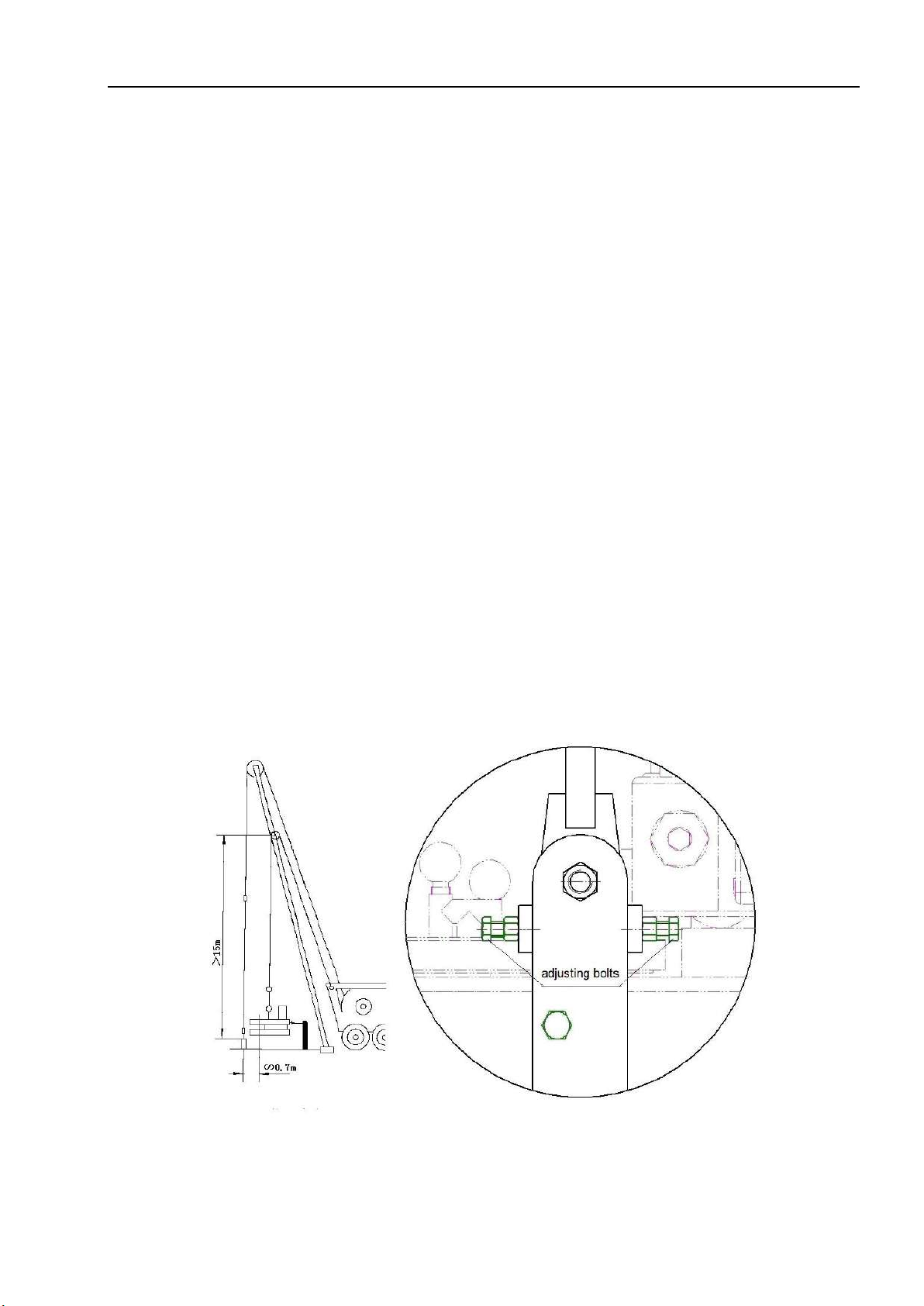

Hanging of power tong

Use a wire rope not less than 1/2in (dia.) as hanging and fixing rope.

Warning: Prior to hang the tong, check wire rope, pulley, shackle and other attachments if worn or

damaged, if well maintained, and lock device if effective. It will cause serious damage on man and

rig equipment in the process of handing the power tong if failure of hanging happens.

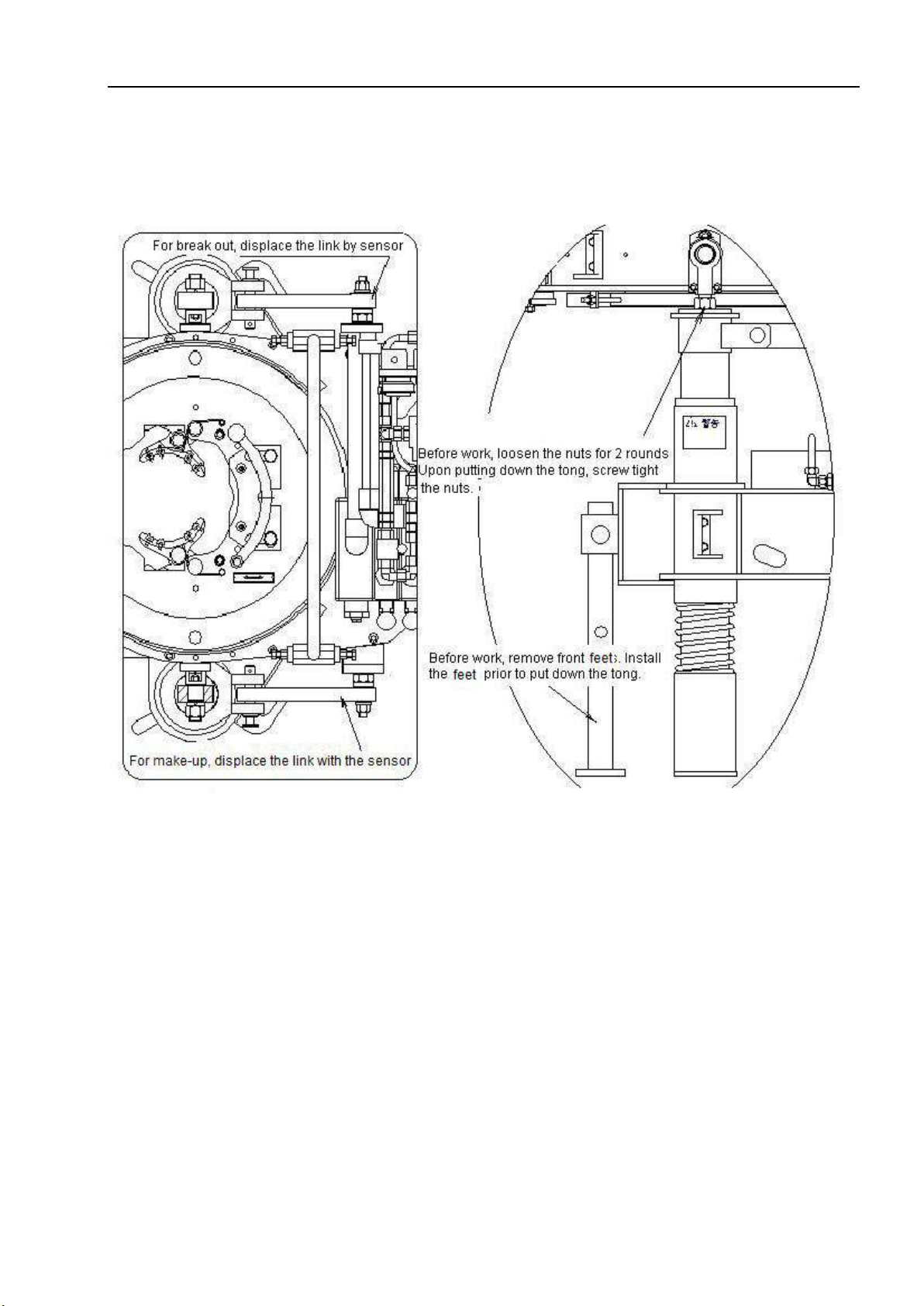

1.2

Fixing of safety rope

Use a wire rope not less than 5/8in(dia.) to connect the tong tail, as safety rope.

Warning: During working, the tong tail part is easy to impact. It is necessary to attach a safety rope

against sliding of backup tong. Bearing connecting, check the rope and its attachments such as

shackles for worn and damage, and check lock device if effective. Failure of wire rope in the

process of handling the power tong will cause severe personal injury and equipment damage.

1.3

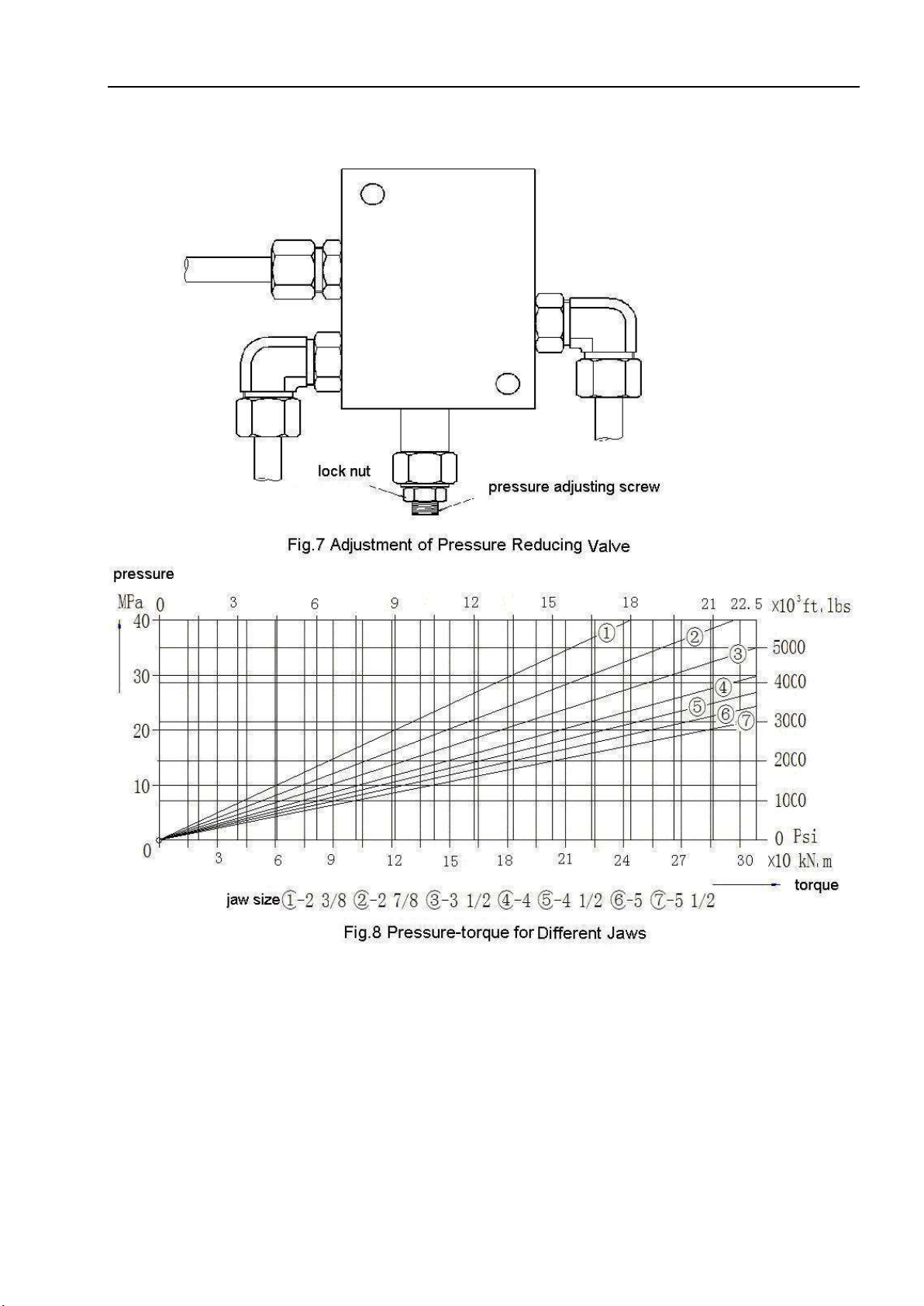

Connecting of hydraulic hoses

Warning: Ensure joints completely sealed. Improper maintenance and operation may cause leaking

of hoses, which will cause environmental pollution. Operators should be familiar with the operation

procedures and

1.4

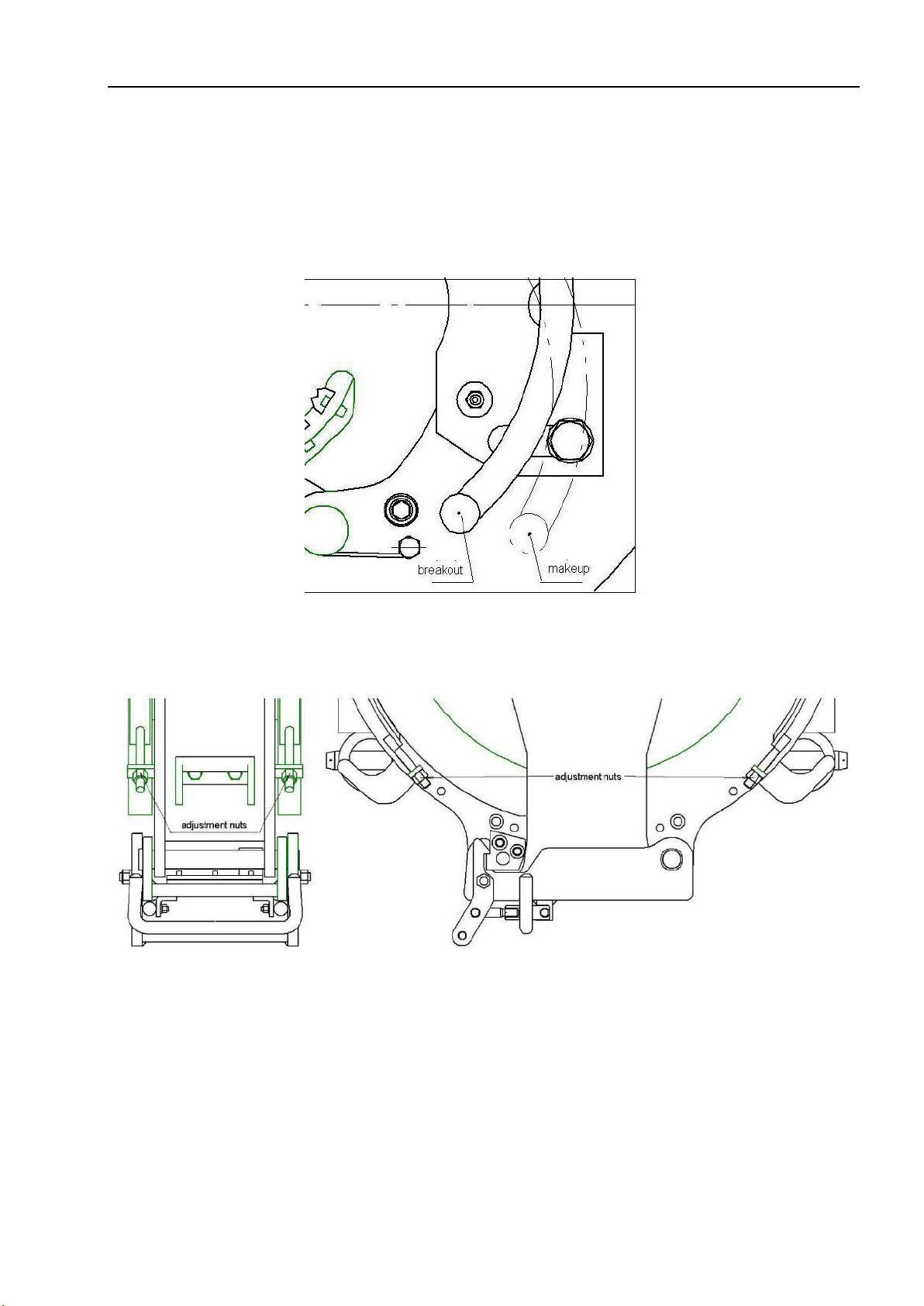

Operating of power tong

Warning: Avoid any part of human body or clothes near the rotating area of the power tong.

Operator and other people should keep away from tong tail power direction to prevent personal

injury and equipment damage.

Warning: Do remember to shut off power unit when replacing jaws of the power tong.

Warning: Never allow to operate the tong when the tong door is open.

Warning: Do not put the tong operation handle at the same location under any situation, or the tong

will fail to control.

1.5

Others

Warning: Do not adjust, maintain, dismantle or lubricate the power tong when the power unit is n.

Warning: Hydraulic hose and seal rings for replacing should be proof pressure tested under 21MPa

(3000psi).

Warning: Remember to use genuine parts manufactured by Goldenman Company.

2.

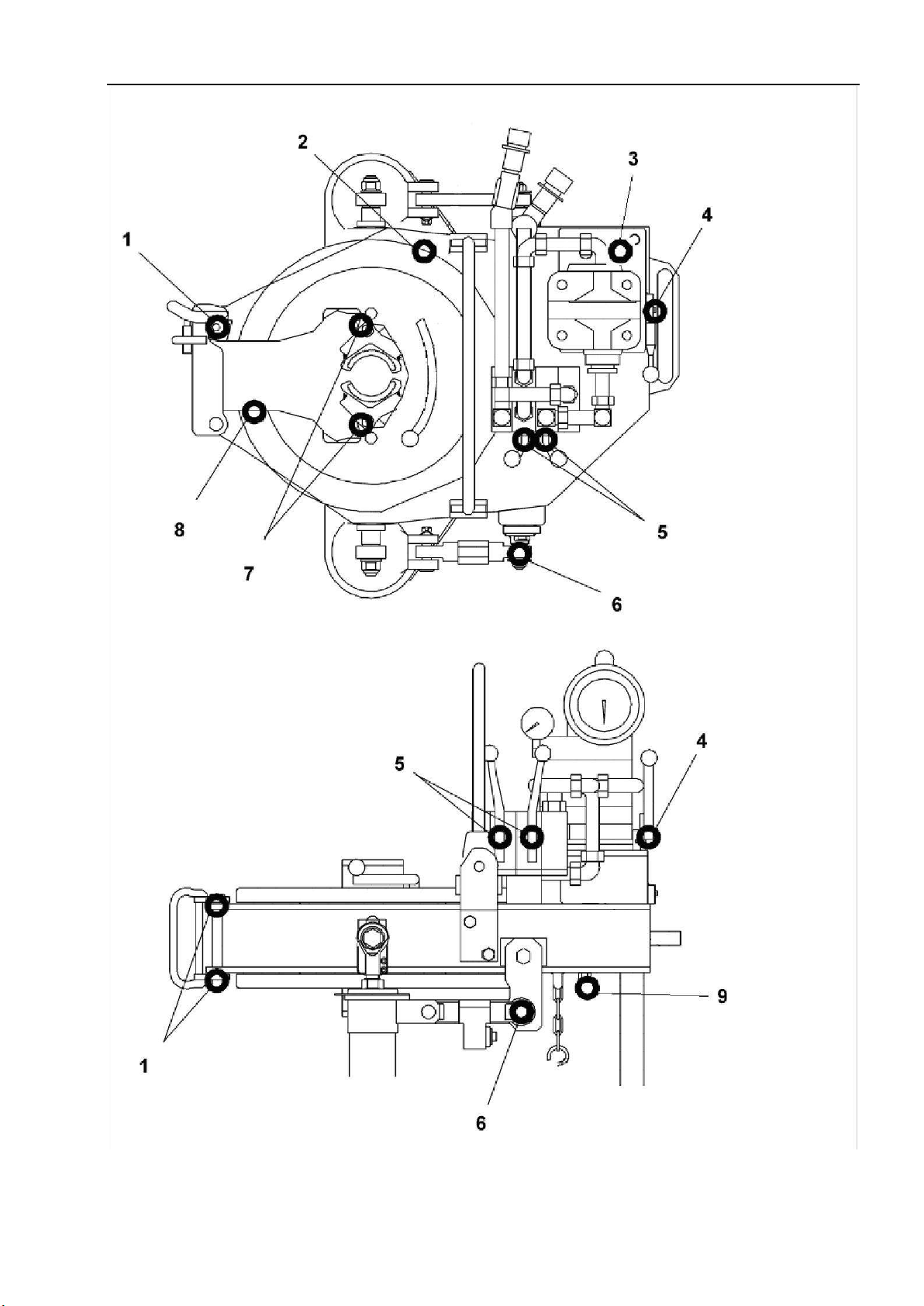

Overview

As one kind of open throat power tong used for making up and breaking out pips in the well