Super Floss

Model 3038EDX

4

Controls And Functions

Main Switch - Turns motor "on" or "off" and supplies current to the heat switch.

Heat Switch - Turns current to the heating element "on" or "off."

Heat Control - Increases or decreases voltage percentage to the tubular wire heating element.

Operating Instructions

Gold Medal FLOSSUGAR is the preferred sugar for your new cotton candy machine. Our

FLOSSUGAR comes in 8 flavors and can change colors for a large variety of combinations to

achieve the best sales. It is packed in handy half-gallon sealed cartons, with an E-Z pour spout for

filling your machine. If you want to “Mix Your Own”— use our FLOSSINE mix and follow the

directions provided.

Most sugar manufactured today is “Extra Fine Granulated” which does have some small particles

which can slip through the openings on the floss band without being melted. If this becomes

objectionable, you can seek out Medium Coarse, or sanding sugars. The larger crystal size will

require more heat to melt. Check the label on the bag of sugar — we commonly see “Free Flowing”

sugar for restaurants, and it contains cornstarch which will burn onto the floss band and clog the

opening. We have also seen some lower priced off-brand “sugar” which is a blend of sugar and

dextrose or corn syrup. This product makes very poor cotton candy. Please make sure you use

quality sugar for your cotton candy machine.

Heat Control Setting Test And Operation

1. Follow the guidelines described on page 3 for supplying power to machine.

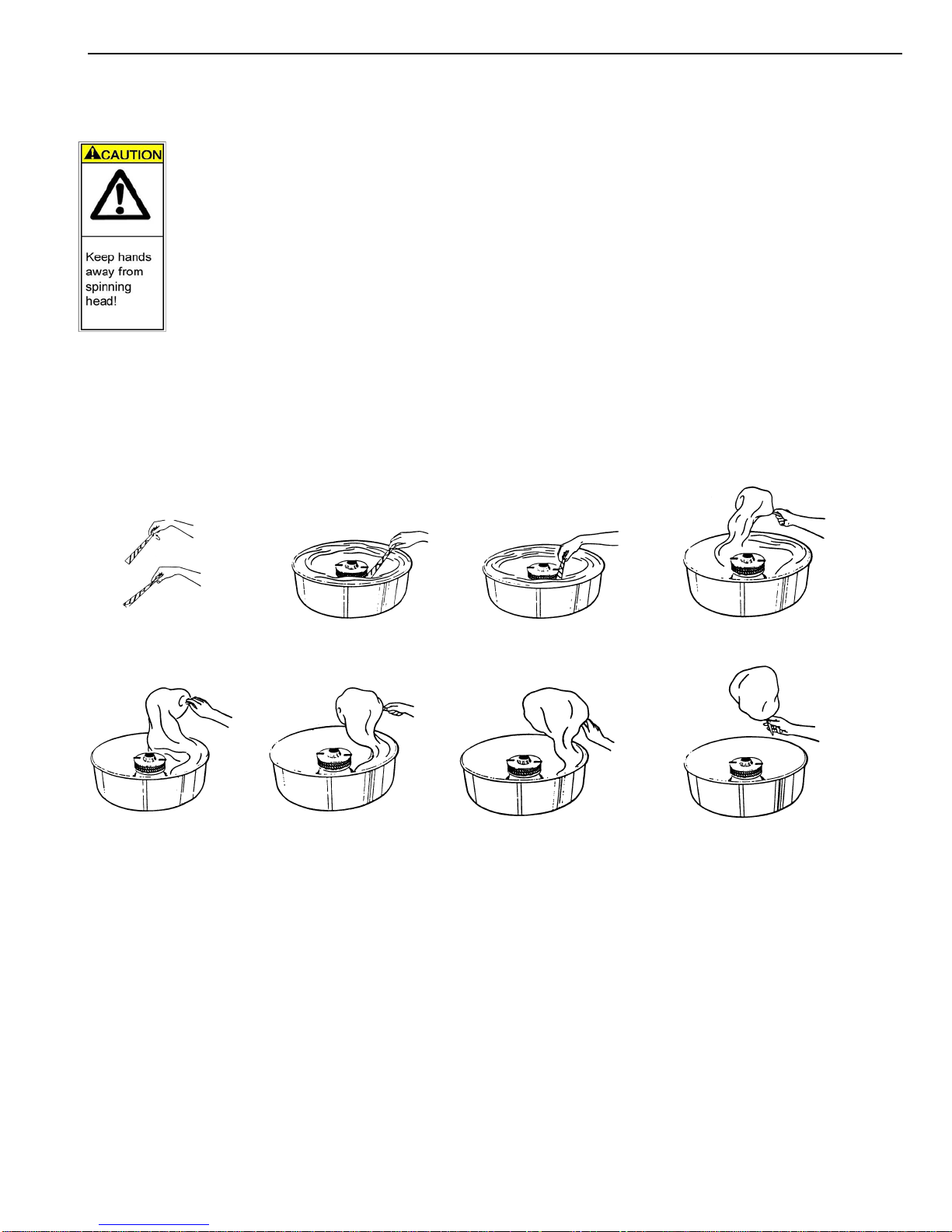

2. With main switch still OFF, fill floss head with sugar through top center opening. Always fill it 90%

full with sugar. This 90% level is necessary to obtain a balanced condition in the floss head. DO

NOT OVERFILL! Excessive vibration will occur if overfilled. Before turning the power on, manually

turn the head to balance out the sugar. Important: NEVER add sugar when motor is running.

3. Turn MAIN SWITCH and HEAT SWITCH "ON."

4. Turn heat control knob clockwise to maximum setting to initiate the fastest possible warm up.

5. The machine should start making floss in 45-50 seconds. When the unit starts making floss, you

must reduce the heat setting. Turn the heat control knob counter clockwise to eliminate smoking.

6. Once you find the ideal setting for the HEAT CONTROL, operate with the setting near this

position each time. If the incoming line voltage changes during the day, the control will

automatically adjust the power to the head to keep the power at the same level as the selected

percent power number.