2

S

HIPPING

I

NSPECTION

All units are securely packed in shipping containers tested

according to ISTAspecifications. The carton must be checked

upon arrival for external damage. If damage is found, a

request for inspection by carrier’s agent must be made in

writing immediately.

Inspect the kit carefully on arrival for damage and screws

or wires which may have come loose in transit. In the event

of damage the consignee should:

1. Make a notation on delivery receipt of any visible

damage to shipment or container.

2. Notify carrier promptly and request an inspection.

3. With concealed damage, carrier must be notified as soon

as possible - preferably within five days.

4. File the claim with the following support documents

within a nine month statute of limitations.

• Original or certified copy of the Bill of Lading, or

indemnity bond.

• Original paid freight bill or indemnity in lieu thereof.

• Original or certified copy of the invoice, showing

trade and other discounts or reductions.

• Copy of the inspection report issued by carrier’s

representative at the time damage is reported to

carrier.

The carrier is responsible for making prompt inspection of

damage and for a thorough investigation of each claim. The

distributor or manufacturer will not accept claims from

dealers for transportation damage.

S

TANDARD

A

IR

HANDLER

I

NSTALLATION

HKS

ELECTRIC

HEATER

KITS

MAY

ONLY

BE

INSTALLED

IN

ARUFXX14YY,

ARPTXX14YY, ASUFXX14YY, ASPTXX14YY, AVPTXX14YY,

DVXXPTC14YY

MODELS

(

WHERE

XX

IS

THE

TWO

-

DIGIT

SIZE

AND

YY

ARE

REVISION

LETTERS

).

WARNING

ONLY

INSTALL

HEATER

KITS

INTO

AN

AIR

HANDLER

THAT

ARE

LISTED

AS

APPROVED

ON

THE

RATING

PLATE

OF

THE

AIR

HANDLER

.

WARNING

T

O

PREVENT

PERSONAL

INJURY

OR

DEATH

WHEN

INSTALLING

IN

A

GARAGE

,

THE

ELEMENT

MUST

BE

AT

LEAST

18”

ABOVE

THE

FLOOR

.

WARNING

T

O

AVOID

PROPERTY

DAMAGE

OR

PERSONAL

INJURY

DUE

TO

FIRE

,

USE

ONLY

COPPER

CONDUCTORS

.

CAUTION

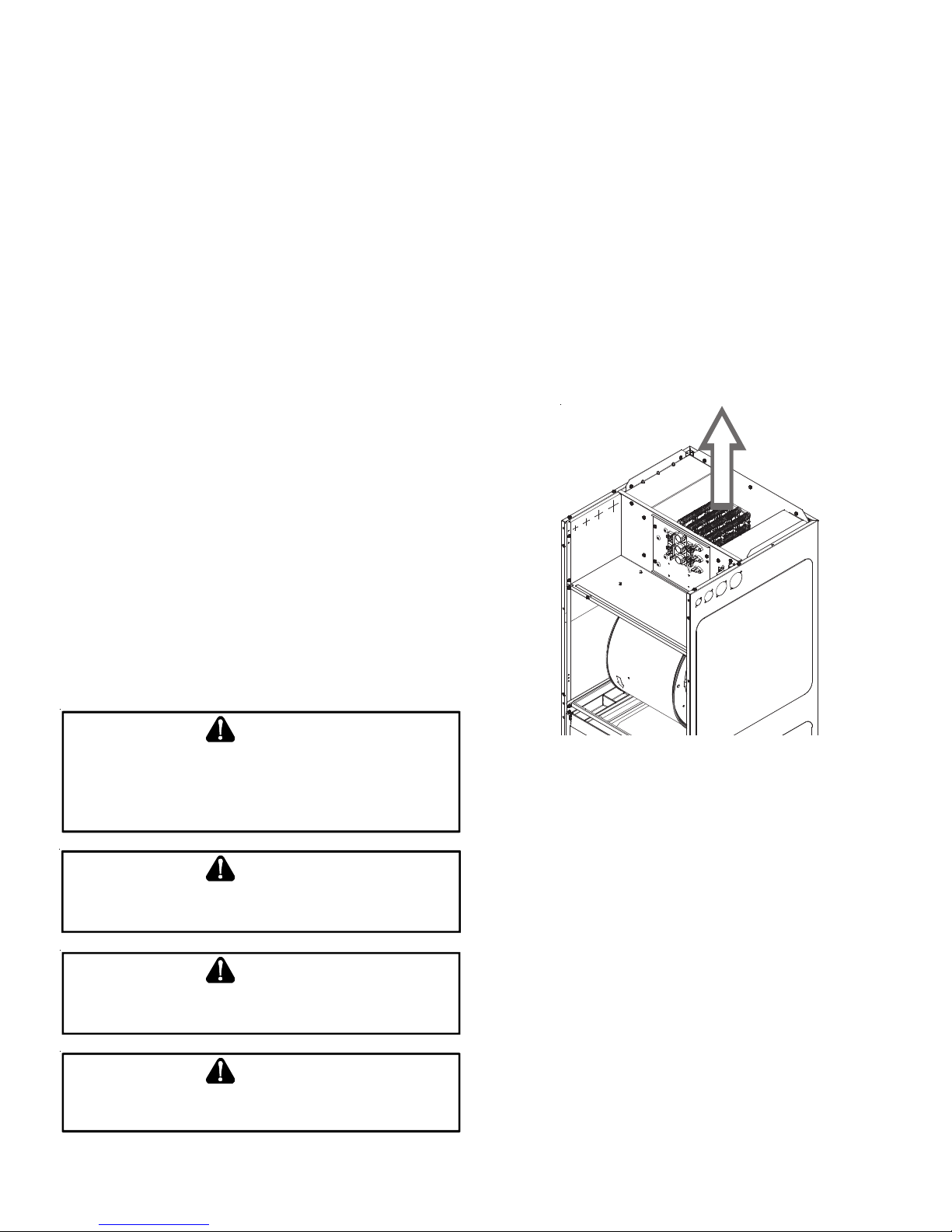

1. Remove the upper access panel from the air handler.

2. Remove and retain the four (4) screws securing the cover

plate. Remove and discard the cover plate.

3. For electric heat kits with circuit breakers, remove the

two screws securing the circuit breaker mounting plate

to the electric heat face plate.

NOTE: The circuit breakers for the 25kW are placed

separately in the carton and are not attached to the

heater plate.

4. Slide the electric heat kit into the opening in the air

handler, making sure the direction of airflow decal

attached to the electric heat face plate is pointing in

the correct direction, and secure the electric heat face

plate using the screws removed in Step 2. Use caution

to not bend or damage the electric heating elements,

the limit switches or fuses during this process. See Figure

1.

Airflow

Direction

Figure 1

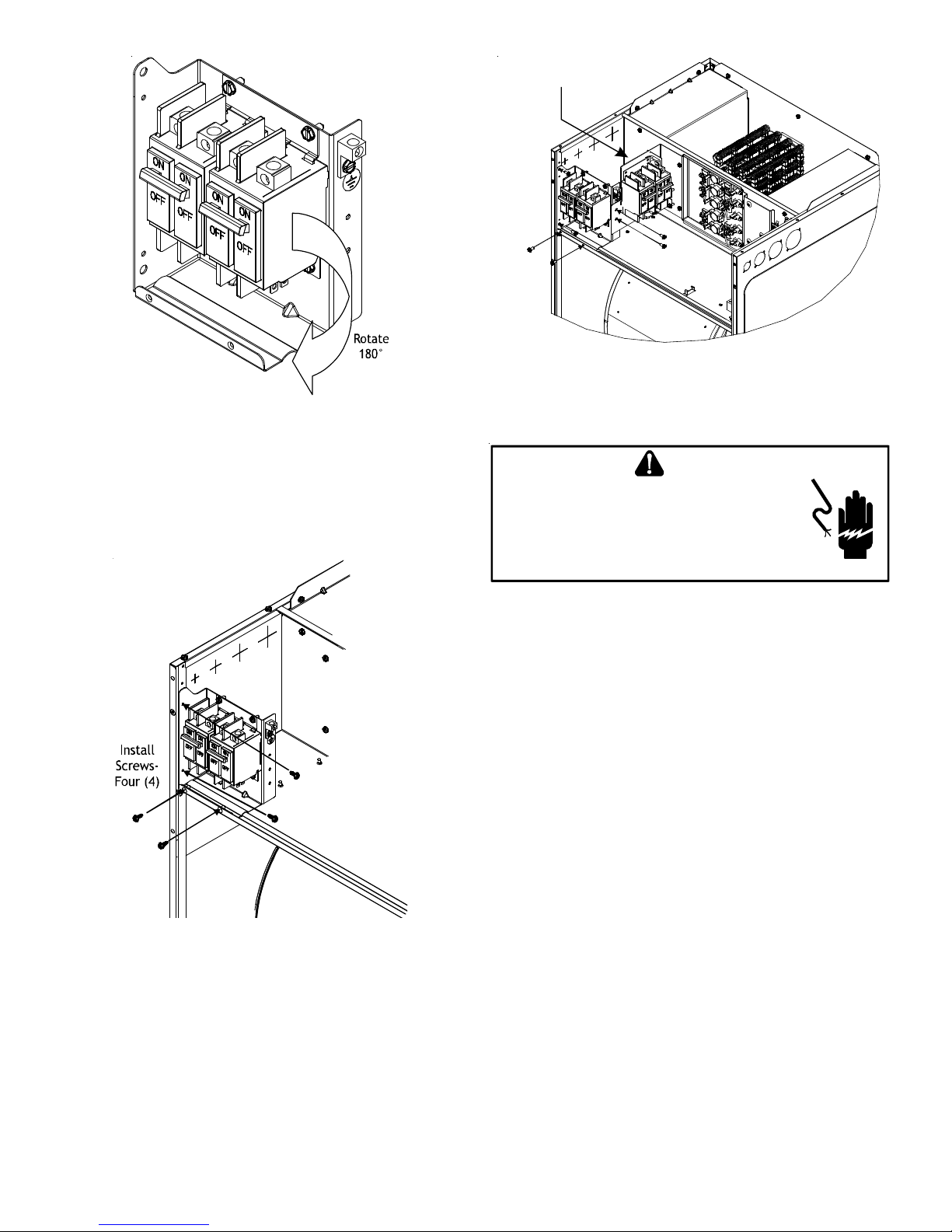

5. For downflow applications with electric heat kits that

have circuit breakers, the circuit breakers must be

rotated 180 degrees (such that the ON position will

be with the circuit breaker handles up). To do so,

remove and retain the 2 screws securing the circuit

breaker clamps, rotate the circuit breakers and

clamps 180 degrees, then use the same 2 screws to

re-secure the circuit breakers. See Figure 2.