6

GENERAL OPERATING INSTRUCTIONS

1. ATTACH MINIMUM 5/8” DIA. GARDEN HOSE TO WATER FAUCET AND FLUSH HOSE.

2. CLOSE WATER FAUCET.

3. ATTACH GARDEN HOSE TO WATER INLET VALVE AT THE PUMP.

4. CONNECT JETTER HOSE TO REEL OR PUMP DISCHARGE CONNECTOR.

NOTE: ONLY THE LARGER DIAMETER HOSE IS CONNECTED TO THE REEL. THE SMALL DIAMETER

HOSE MUST BE COMPLETELY REMOVED FROM THE REEL BEFORE ANY CONNECTIONS CAN BE MADE.

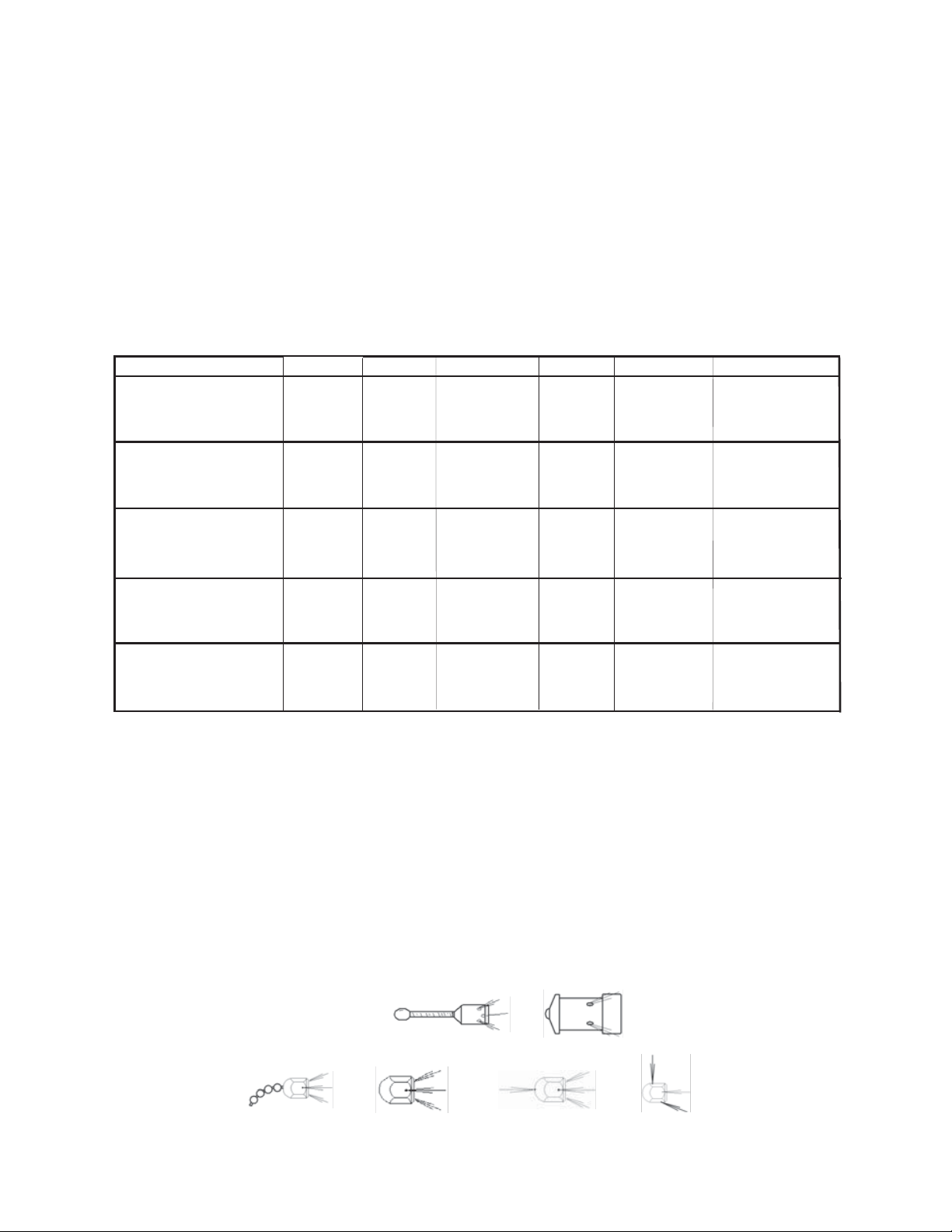

5. ATTACH NOZZLE FINGER TIGHT PLUS TURN 1/2 TURN MAX. WITH WRENCH.

CAUTION: OVER TIGHTENING MAY BLOCK JETS AND INTERFERE WITH WATER SUPPLY.

6. APPROXIMATELY 6 FEET FROM NOZZLE MARK HOSE WITH ELECTRICAL TAPE, ETC.

7. OPEN WATER INTAKE AND DISCHARGE VALVES AT PUMP.

8. OPEN WATER FAUCET AGAIN TO PRIME PUMP, FLUSH JETTER HOSE AND NOZZLE.

NOTE: AN EQUAL AMOUNT OF WATER MUST ESCAPE FROM EACH NOZZLE ORIFICE.

9. PUSH JETTER HOSE INTO THE DRAIN PIPE UNTIL HOSE MARKER DISAPPEARS, IF POSSIBLE.

10. START THE MOTOR/ENGINE.

● MOTOR STARTING PROCEDURE FOR ELECTRIC DRIVEN MODELS:

A. PLUG CORD INTO A GROUNDED 110 VOLT RECEPTACLE.

B. MOVE SWITCH TO “ON” POSITION.

● ENGINE STARTING PROCEDURE FOR GASOLINE POWERED MODELS WITH RECOIL STARTER:

A. TURN THE FUEL VALVE TO THE ‘ON” POSITION.

B. MOVE THE CHOKE LEVER TO THE “CLOSE” POSITION.

C. MOVE THE THROTTLE LEVER SLIGHTLY TO THE “LEFT”.

D. TURN THE ENGINE SWITCH TO THE “ON” POSITION.

E. PULL STARTER GRIP LIGHTLY UNTIL RESISTANCE IS FELT, THEN PULL BRISKLY. RETURN GRIP GENTLY.

F. GRADUALLY MOVE THE CHOKE LEVER TO THE :OPEN” POSITION.

G. MOVE THE THROTTLE LEVER TO THE DESIRED ENGINE SPEED.

● ENGINE STARTING PROCEDURE FOR GASOLINE POWERED MODELS WITH ELECTRIC STARTER:

A. TURN THE FUEL VALVE TO THE ‘ON” POSITION.

B. MOVE THE CHOKE LEVER TO THE “CLOSE” POSITION.

C. MOVE THE THROTTLE LEVER SLIGHTLY TO THE “LEFT”.

D. TURN THE ENGINE SWITCH TO THE “START” POSITION AND HOLD IT THERE (5 SECONDS MAX.)

UNTIL ENGINE STARTS. AFTER THE ENGINE STARTS, ALLOW THE ENGINE SWITCH TO

RETURN TO THE “ON” POSITION.

E. GRADUALLY MOVE THE CHOKE LEVER TO THE “OPEN’ POSITION.

F. MOVE THE THROTTLE LEVER TO THE DESIRED ENGINE SPEED.

● ENGINE STARTING PROCEDURE FOR PROPANE POWERED MODELS WITH ELECTRIC STARTER:

A. CONNECT PROPANE HOSE TO TANK.

B. OPEN TANK VALVE.

C. MOVE THE THROTTLE LEVER SLIGHTLY TO THE “LEFT”.

D. PUSH PRIMER BUTTON FOR APPROXIMATELY 3 SECONDS.

E. TURN THE ENGINE SWITCH TO THE “START” POSITION AND HOLD IT THERE ( 5 SECONDS MAX.) UNTIL

ENGINE STARTS. AFTER THE ENGINE STARTS, ALLOW THE ENGINE SWITCH TO RETURN TO THE

“ON” POSITION.

F. MOVE THE THROTTLE LEVER TO THE DESIRED ENGINE SPEED.

NOTE: FOR ADDITIONAL INFORMATION ON HOW TO START YOUR ENGINE REFER TO THE ENGINE

OPERATING MANUAL SUPPLIED BY THE MANUFACTURER.

11. ADJUST PRESSURE WITH THE PRESSURE REGULATOR KNOB.

12. START JETTING.

TO NEGOTIATE TIGHT PIPE TURNS OR DIFFICULT WASTE LINE BLOCKAGES IT MAY BE NECESSARY

TO ROTATE OR TWIST THE HOSE NEAR THE DRAIN OPENING. ONCE YOU HAVE CUT THROUGH

THE BLOCKAGE, PULL HOSE BACK SEVERAL FEET. PASS HOSE AGAIN THROUGH SAME STOP-

PAGE LOCATION AND ADVANCE TO NEXT LARGER DRAIN LINE CONNECTION. SLOWLY RETRIEVE

HOSE FROM DRAIN PIPE TO ALLOW A THOROUGH CLEANING JOB.