Table of contents

4

Table of contents

Disclaimer .................................................................................................................................................................................2

Revision history........................................................................................................................................................................2

Introduction...............................................................................................................................................................................3

Table of contents ......................................................................................................................................................................4

General ......................................................................................................................................................................................5

Working principle..................................................................................................................................................................5

Terms and conditions of sale and warranty...........................................................................................................................6

Delivery......................................................................................................................................................................................7

General ................................................................................................................................................................................7

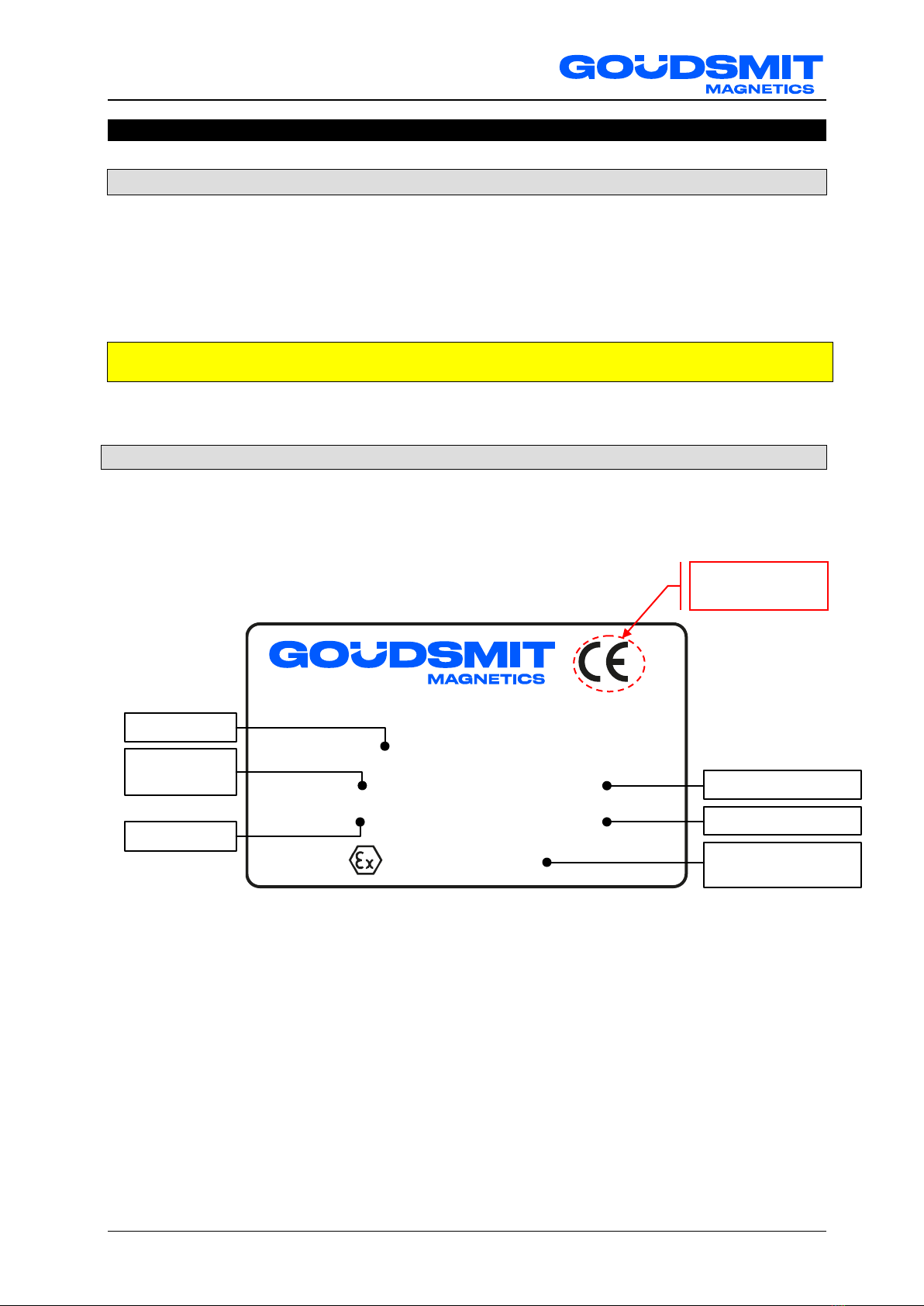

Identification plate ................................................................................................................................................................7

ATEX Markings (if applicable) ........................................................................................................................................8

ATEX explosive zone measures .....................................................................................................................................9

Safety.......................................................................................................................................................................................10

General ..............................................................................................................................................................................10

Danger of dust explosion ....................................................................................................................................................10

Danger of magnetic field.....................................................................................................................................................10

Separator specifications ........................................................................................................................................................12

Intended use / user indications ...........................................................................................................................................12

Separator specifications .....................................................................................................................................................13

Working principle................................................................................................................................................................14

Construction .......................................................................................................................................................................15

Magnet bar cleaning / Fe disposal ......................................................................................................................................17

Installation...............................................................................................................................................................................18

Transport and placing procedures ......................................................................................................................................18

Magnet bar protection.........................................................................................................................................................19

Gasket material / grounding................................................................................................................................................19

Electrical connections & EX .........................................................................................................................................19

Start-up....................................................................................................................................................................................20

Maintenance............................................................................................................................................................................21

Magnet bars .......................................................................................................................................................................21

Cleaning & ATEX................................................................................................................................................................21

Malfunctions/Service..............................................................................................................................................................22

Spare parts..............................................................................................................................................................................23

Storage and Dismantling........................................................................................................................................................24