Hydrohansu – 11/2022 – v2.2 3

Table of contents

Disclaimer........................................................................................................................................................................................2

Version history.................................................................................................................................................................................2

Preface............................................................................................................................................................................................2

Table of contents .............................................................................................................................................................................3

Safety ..............................................................................................................................................................................................4

General safety instructions ....................................................................................................................................................................4

In case of emergency ............................................................................................................................................................................4

Damage by magnetic field .....................................................................................................................................................................4

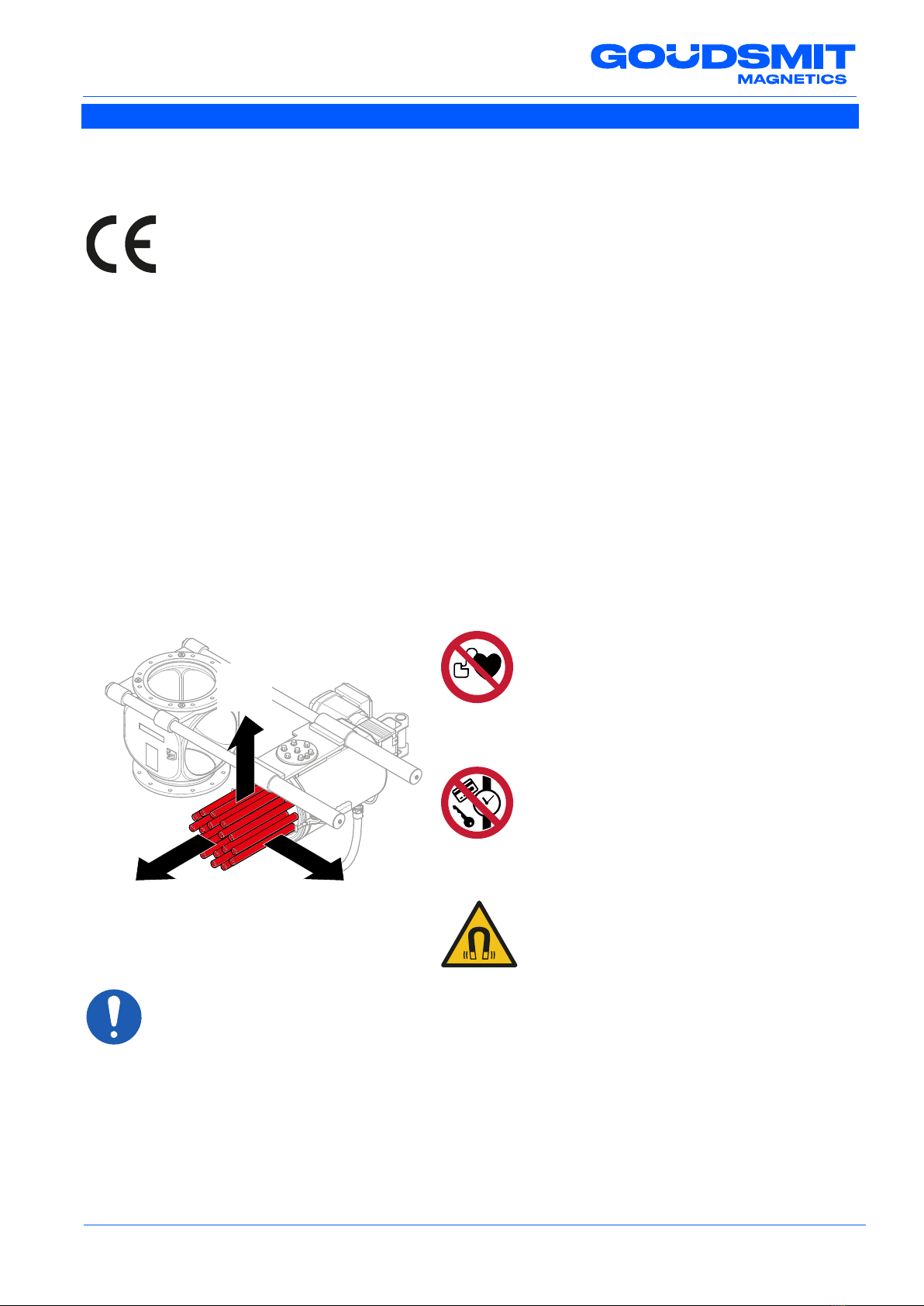

Product Standards and Directives ...................................................................................................................................................5

CE marking............................................................................................................................................................................................5

Directives ..............................................................................................................................................................................................5

Occupational and public exposure limit values for (electro) magnetic fields ...........................................................................................5

General information .........................................................................................................................................................................6

Warranty conditions for previously delivered devices without a corresponding control unit.....................................................................6

Notes.....................................................................................................................................................................................................6

Specifications ..................................................................................................................................................................................7

Design ...................................................................................................................................................................................................7

Function description ..............................................................................................................................................................................7

Scope of application ..............................................................................................................................................................................7

Food contact application – use in food flows..........................................................................................................................................7

Temperatures ........................................................................................................................................................................................7

Supply voltage.......................................................................................................................................................................................7

Air pressure ...........................................................................................................................................................................................8

Nitrogen.................................................................................................................................................................................................8

Air quality ..............................................................................................................................................................................................8

Air purge on seal (air purity requirements) ........................................................................................................................................8

Compressed air ................................................................................................................................................................................8

ATEX...............................................................................................................................................................................................9

Markings................................................................................................................................................................................................9

Description of the ATEX options ..........................................................................................................................................................10

ATEX measures ..................................................................................................................................................................................10

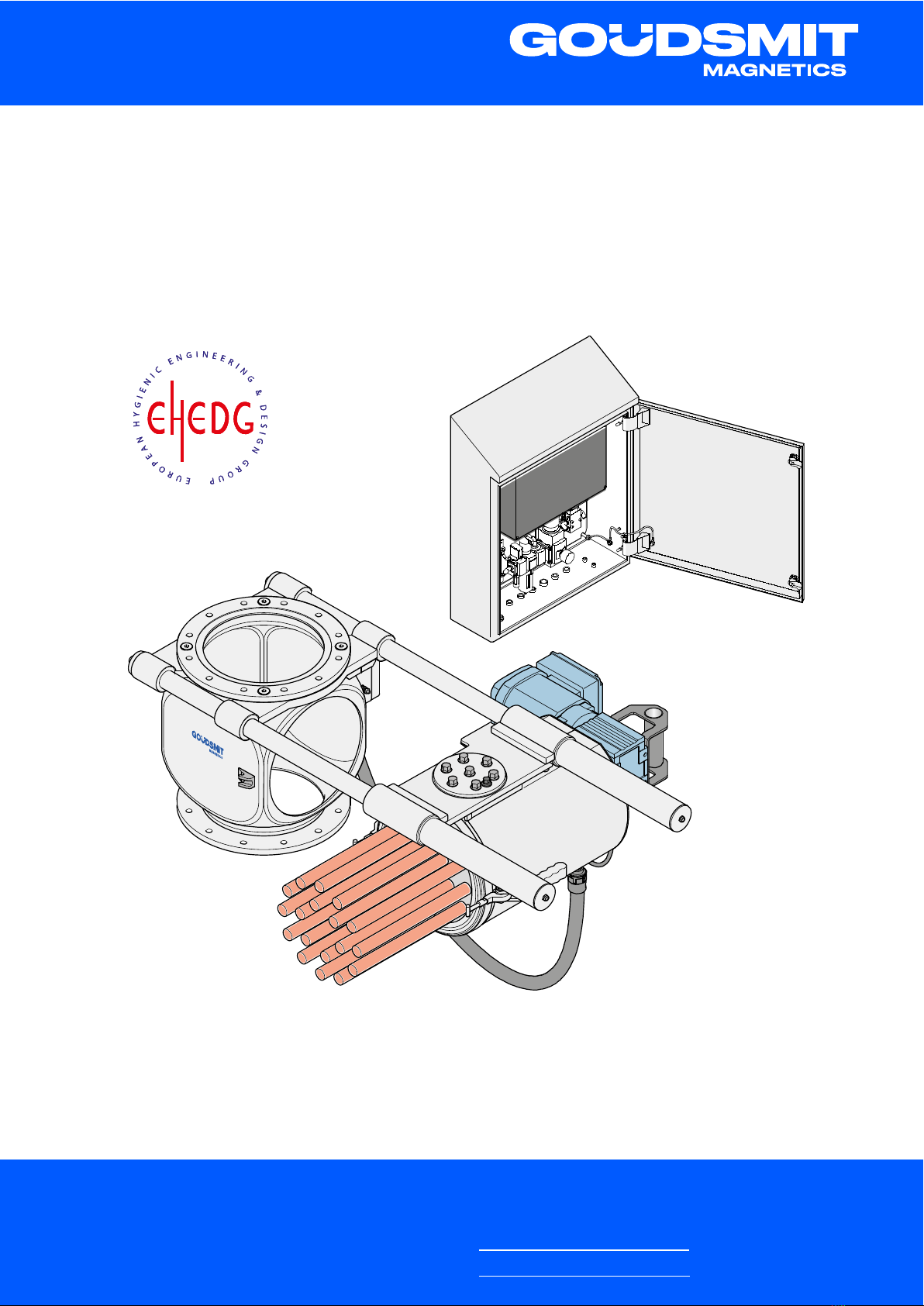

Device overview ..................................................................................................................................................................................11

Scope of delivery .................................................................................................................................................................................11

Identification plate................................................................................................................................................................................12

Endurance test ....................................................................................................................................................................................12

Accessories .........................................................................................................................................................................................12

Transport and installation ..............................................................................................................................................................13

Transport.............................................................................................................................................................................................13

Installation of the device ......................................................................................................................................................................13

Preventing electrostatic discharge .......................................................................................................................................................14

Working principle...........................................................................................................................................................................15

Maintenance and inspection ..........................................................................................................................................................16

Cleaning instructions ...........................................................................................................................................................................16

Cleaning of the magnetic bar tubes.................................................................................................................................................17

Cleaning the O-ring with housing ....................................................................................................................................................18

Flux density measurement of the magnetic bars ..................................................................................................................................19

Sensor adjustment “magnetic bars in cleaning mode”..........................................................................................................................20

Control box ....................................................................................................................................................................................21

Malfunctions ..................................................................................................................................................................................22

Service, storage and disassembly .................................................................................................................................................23

Customer service.................................................................................................................................................................................23

Spare parts..........................................................................................................................................................................................23

Storage and disassembly (recycle) ......................................................................................................................................................23