2

WARNING! FOR THE SAFETY OF PERSONS IT’S IMPORTANT

TO FOLLOW THIS INSTRUCTIONS!

KEEP CAREFULLY THIS INSTRUCTIONS!

The present manual instruction is headed to installers and specia-

lized stuff of “Energy utilization devices”, with the knowledge of

construction parameters and of protection against accidents for

automated gates. The materials used must be certified and fit the

usage conditions of the automation.

Keep away children from command devices of the gate (remote

control, pushbuttons,...).

Don’t let that children or animals play nearby the gate.

Periodically check the gate, verifying that there are not present

unbalancing, signs of usury or damage. In this case stop the

usage of the gate as his functioning, in such conditions, could be

source of damages to things or persons.

Before any installation, regulation or cleaning operation on the

gate and of his components, unplug feeding line by the proper

thermo-magnetically switch, set before the installation, and dis-

connect also any battery.

Control board must be connected to feeding line by an Omni-polar

switch, with opening distance between contacts not lower then

3mm. Such device must be protected from accidentally reactiva-

tion (installation on a lockable box).

Hang signs, easily visible, that inform of the presence of a moto-

rized gate.

WARNING! A NOT CORRECT INSTALLATION CAN CAUSE

SERIOUS DAMAGES!

FOLLOW ALL THE INSTALLATION INSTRUCTION!

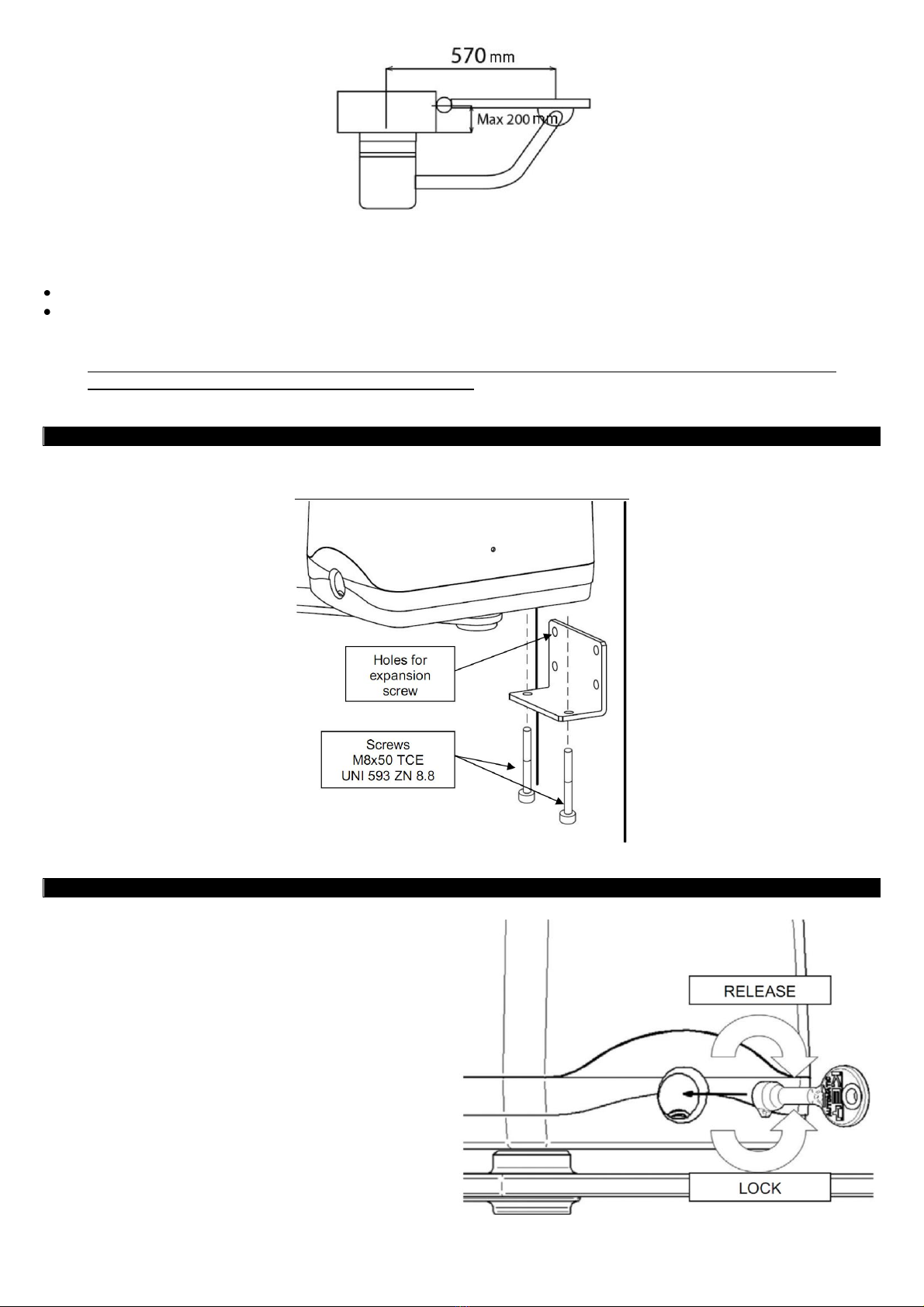

The motor is destined to motorize swinging gates with a maximum

length of 2m. The motor can be installed even at the right then at

the left side of the gate.

The device must be destined exclusively to the usage it was con-

ceived for. Any other usage is to be considered improper and

therefore dangerous.

Control pushbuttons have to be installed at an height between

1.5m and 1.8m, in a position not accessible by children or under

age, in direct view of the gate but distant of it. They must be pro-

tected by unauthorized usage and set up in order to avoid any ac-

cidentally activation.

Not observing the described notes could cause damages to persons, animals or objects. In such

case the producer can’t be considered responsible.

Fix advising labels against crushing in a visible position or in proximity of fixed commands.

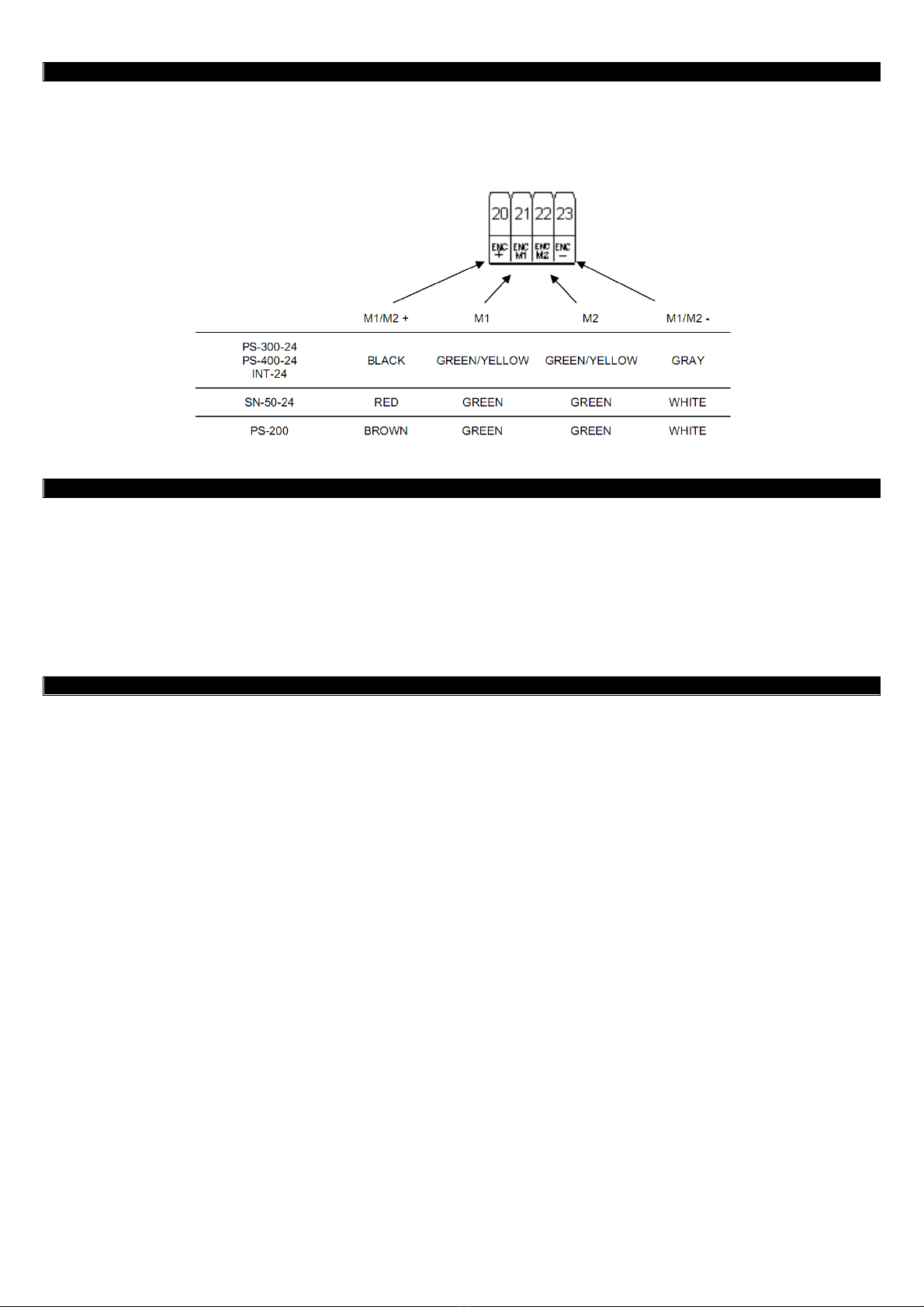

Permanently fix labels relative to the manual release and put them close to the manoeuvre device.

The dicitures must be visible also after the installation of equipment. Otherwise if the diciture can turn out hidden after the installation, it must be

mention in the instructions.

Movement motors must be supplied by a label that indicate to keep children far from the door during motion, or put the appropriate symbol (ISO

3864, see symbol).

Hold the transmitter far away from children and don’t allow them to play with command devices.

Complete the system by installing safety devices like: photocells and rubber edges.

It’s absolutely necessary that, before the installation of motors, the door is supplied by leafs mechanical stops.

Motors with systems sensible to pressure must be supplied with a label that indicate: ATTENTION CRUSHING RISK.

3

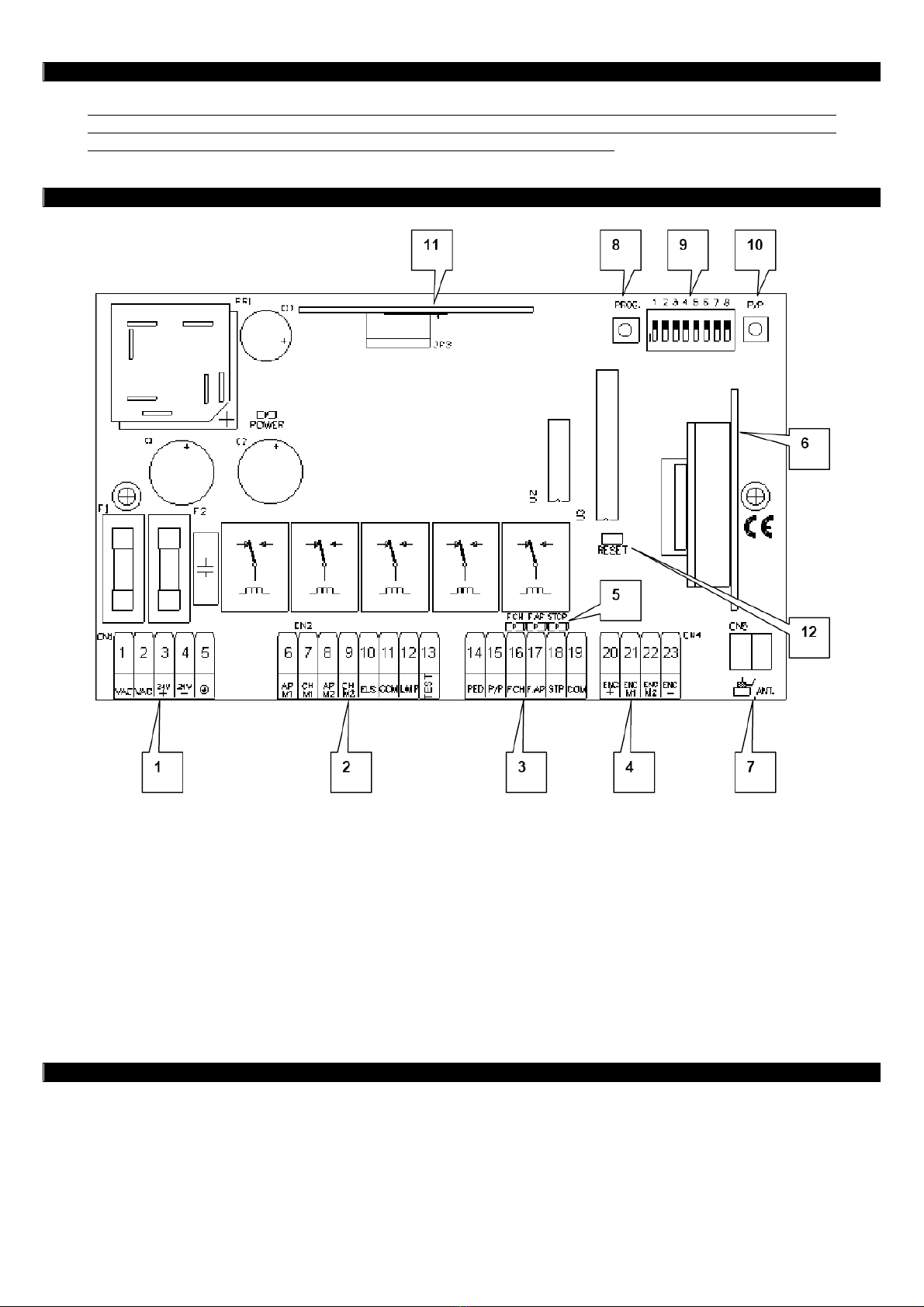

FIXING TO THE GATE AND PRELIMINARY CHECKS