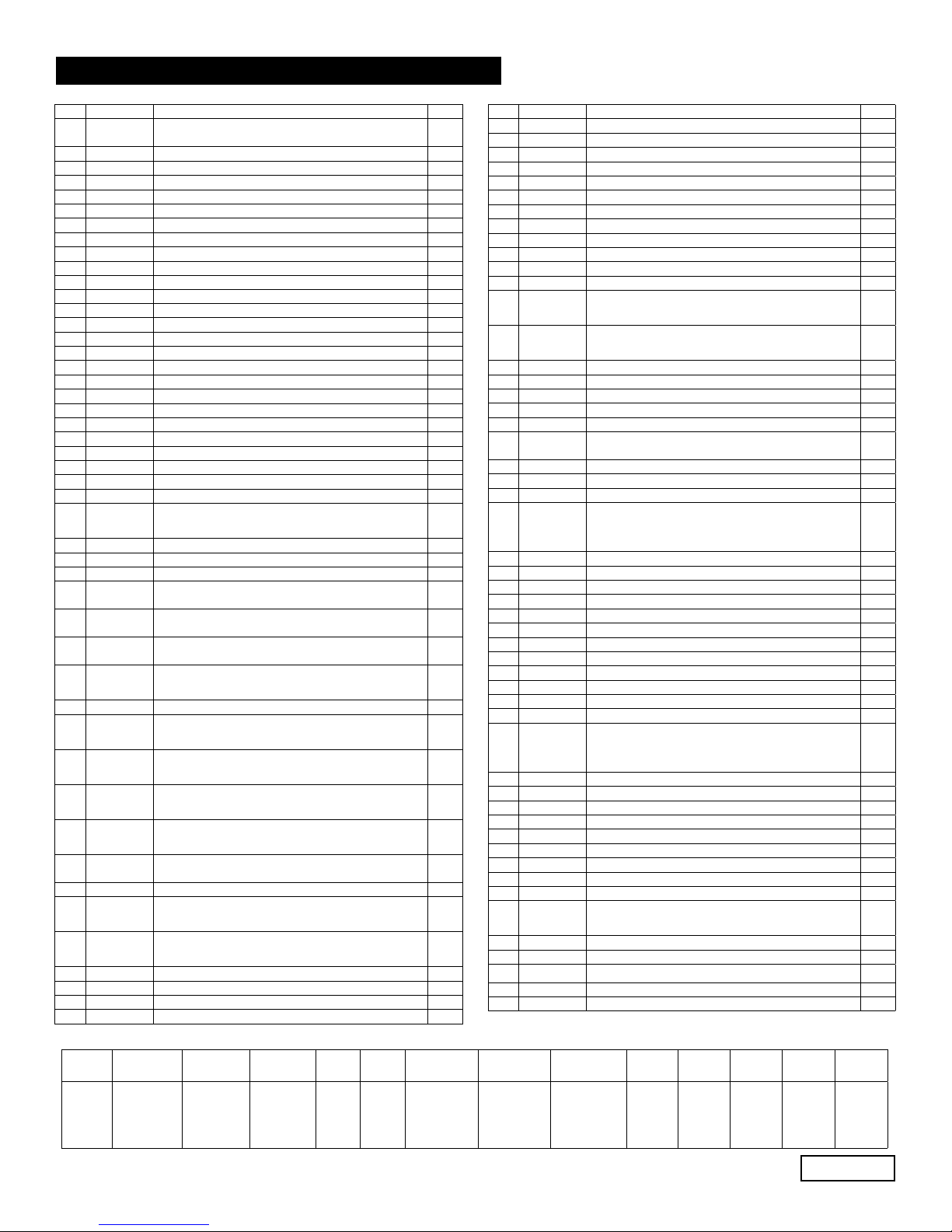

Page 20

GENERAL PUMP A member of the Interpump Group

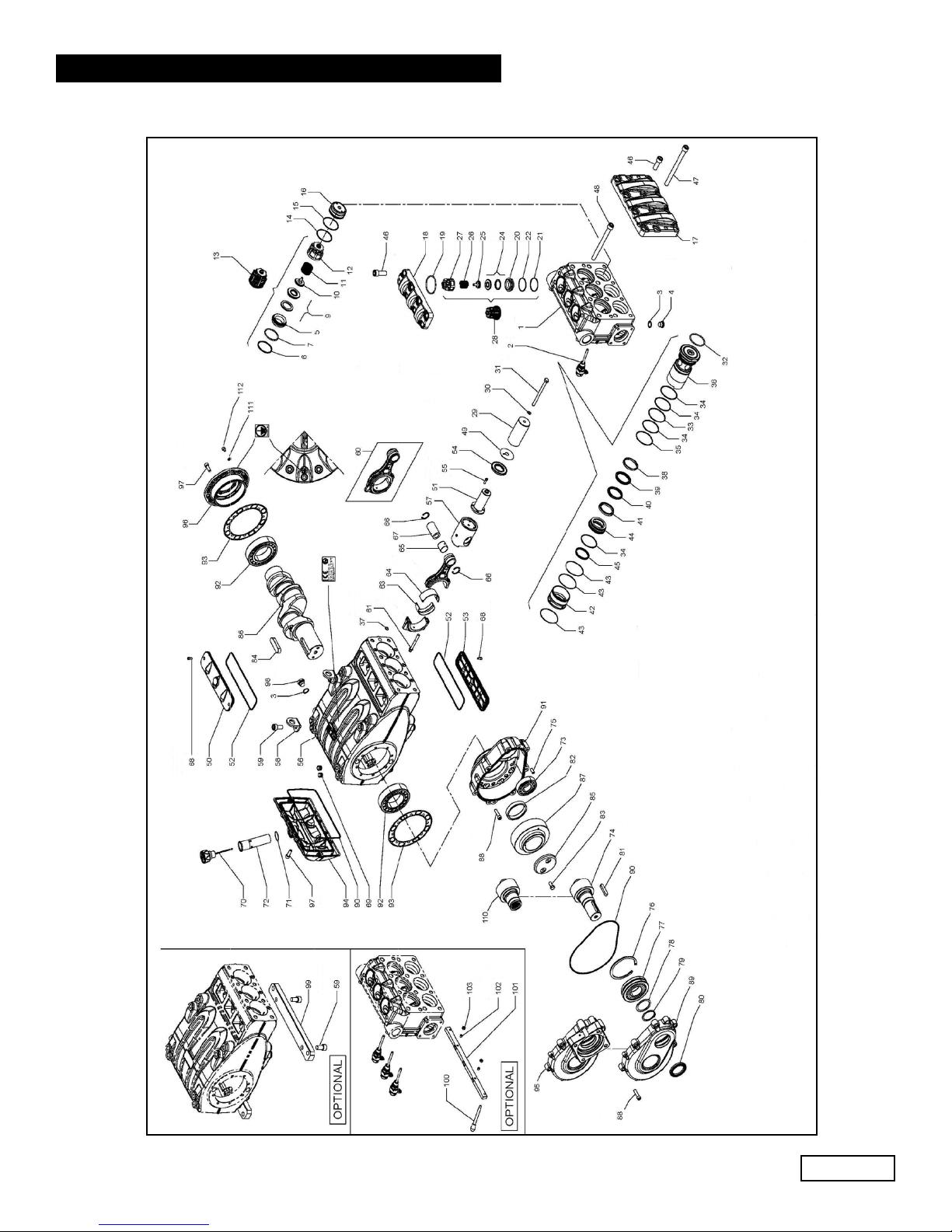

MF45/50/55 SERIES

REPAIR KITS

Item Part # Description QTY.

50 F73150022 CLOSED INSPECTION COVER 1

51 F73050636 PLUNGER GUIDE ROD 3

52 F90414800 OR Ø 202.8X3.53 2

53 F73150122 OPEN ISPECTION COVER 1

54 F90168500 RAD. RING Ø 40.0X72.0X7.0/8.5 3

55 F99188400 SCREW M6X20 12

56 F73010213 PUMP CASING 1

57 F79050443 PLUNGER GUIDE 3

58 F73210674 LIFTING BRACKET 2

59 F99513000 SCREW M16X30 4

60 F73030301 CONNECTING ROD ASSY. 3

61 F99378800 CONNECTING ROD SCREW 6

63

F90928300

F90928100

F90928200

CONROD HEAD SEMI-BUSHING LOWER - INF

CONROD HEAD SEMI-BUSHING LOWER +0.25

CONROD HEAD SEMI-BUSHING LOWER +0.50

3

64

F90928000

F90928400

F90958500

CONROD HEAD SEMI-BUSHING UPPER - INF

CONROD HEAD SEMI-BUSHING UPPER +0.25

CONROD HEAD SEMI-BUSHING UPPER +0.50

3

65 F90917300 CONROD BUSHING 3

66 F90069700 STOP RING Ø 35 6

67 F97745000 SPINDLE 3

68 99183700 SCREW M6X14 4

69 98206000 HOLE PLUG Ø 15 6

70 F98233500

F98233600

OIL FILLING PLUG G1”

OIL FILLING PLUG G1” - ATEX 1

71 90361600 OR Ø 34.65X1.78 1

72 F73210295 TUBE FOR OIL FILLING PLUG, G1” 1

73 F91854000 CY. ROLLER BEARING 1

74

F10076735

F10076835

F10076935

F10082255

PINION, Z24 Ø 1.875, HELICOL

PINION, Z21 Ø 2.238, HELICOL

PINION, Z18 Ø 2.722, HELICOL

PINION, Z19 Ø 3.211, HELICOL

1

75 F97623000 TMP. CYL PIN. Ø 10.0X24.0 2

76 F90101000 STOP RING Ø 120 1

77 F91859900 ADJUST. ROLLER BEARING 1

78 F73210455 BEARING SUPPORT RING 1

79 F90081000 STOP RING Ø 55 1

80 F90172400 RAD. RING, Ø 55.0X75.0X8.0, VITON 1

81 F91500500 TAB, 14.0X9.0X60.0 1

82 F73210589 RING GEAR SUPPORT RING 1

83 9936700 SCREW M10X25 2

84 F91511000 TAB, 22.0X14.0X80.0 1

85 F74213255 RING GEAR STOP 1

86 F73020035 CRANKSHAFT C.70 1

87

F10077035

F10077135

F10077235

F10082355

RING GEAR, Z46 R.1.875 HELICAL

RING GEAR, Z47 R.2.238 HELICAL

RING GEAR, Z49 R.2.722 HELICAL

RING GEAR, Z61 R.3.211 HELICAL

1

88 F99371000 SCREW M10X40 15

89 F73210113 REDUCTION GEAR COVER 1

90 F90415000 OR, Ø 253.6X3.53 2

91 F73210013 REDUCTION GEAR BOX 1

92 F91881000 CY. ROLLER BEARING 2

93 F73210384 SIDE SEAL 2

94 F73160022 CASING COVER 1

96 F73150222 BEARING COVER 1

97 F99368600 SCREW M10X30 14

98

F98218700

F98218700

F98208150

PLUG G1/2”X10

PLUG G1/2”X10 - ATEX

PLUG G1/2”X13 - ATEX

2

1

1

99 F73200064 FOOT 2

100 F94540000 LEVER M8X107 1

101 F73215864 VALVE LIFTER BRACKET 1

102 F99301800 SCREW M8X10 2

103 F92221800 SCREW M8X1.5X5X13 2

Item Part # Description QTY.

1F73121115

F73121215

MANIFOLD (45-50)

MANIFOLD (55) 1

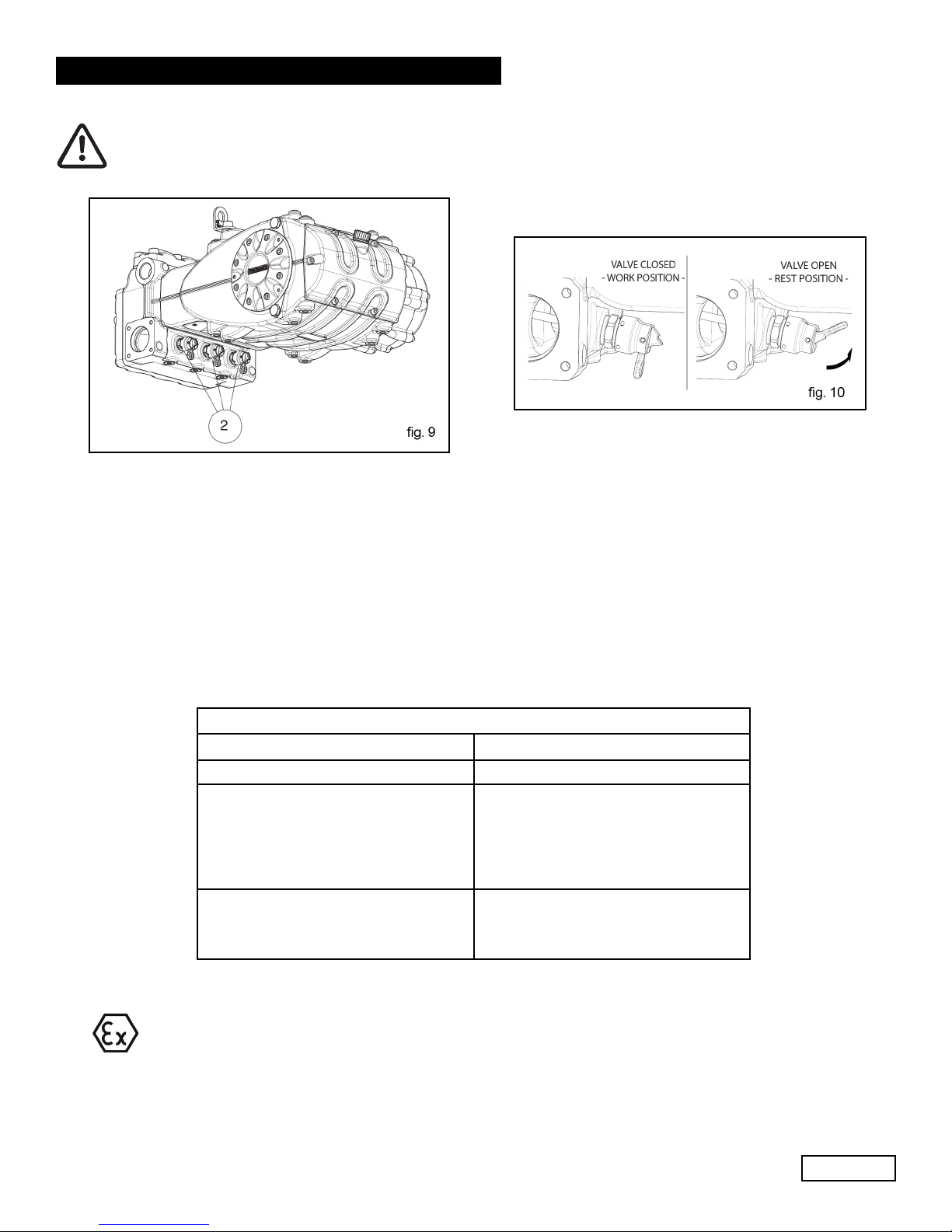

2 F10755401 VALVE OPENING DEVICE 3

3 96751400 WASHER Ø 21.5X27X1.5 5

4 F98218500 STEEL PLUG 3

5 F36206666 INLET VALVE HOUSING 3

6 F90527000 ANTI-EXTRUSION RING, Ø 61.2X67X2 3

7 F90410500 OR Ø59.62X3.53 3

9 F36208701 BALL VAVLE ASSY. 3

10 F36208951 INTERNAL VALVE GUIDE 3

11 F94769800 SPRING, Ø 41.5X37.9

3

12 F36206005 INLET VALVE GUIDE 3

13 F36715001 INLET VALVE UNIT 3

14 F90391100 OR Ø 66.35X2.62 3

15 F90528200 ANTI-EXTRUSION RING, Ø 68.0X72.0X1.5 3

16 F73221556 INLET VALVE PLUG 3

17 F73221415 INLET VALVE COVER 1

18 F73210915 OUTLET VALVE COVER 1

19 F90412000 OR, Ø 68.28X3.53 3

20 F36206766 OUTLET VALVE HOUSING 3

21 F90526000 ANTI-EXTRUSION RING Ø 51.5X56.0X1.5 3

22 F90389000 OR Ø 50.47X2.62 3

24 F36208801 BALL VALVE ASSY. 3

25 F36206766 INTERNAL VALVE GUIDE 3

26 F94760500 SPRING Ø28.5X32 3

27 F36206105 OUTLET VALVE GUIDE 3

28 F36207701 OUTLET VALVE UNIT 3

29

F73040309

F73040409

F73040509

PLUNGER Ø 45X117

PLUNGER Ø 50X117

PLUNGER Ø 55X117

3

30 F96710500 WASHER , Ø 10.0X18.0X0.9 3

31 F99383000 SCREW M10X140 3

32 F90411500 OR Ø 63.5X3.53 3

33 F90528550

F90527000

ANTI-EXTRUSION RING, Ø 72.9X77.0X1.5 (MF45-50)

ANTI-EXTRUSION RING, Ø 79.8X80.0X1.5 (MF55) 3

34 F90391400

F90391350

OR, Ø 72.69X2.62 (MF55)

OR, Ø 71.12X2.62 (MF45-50) 12

35 F90528650

F90528400

ANTI-EXTRUSION RING, Ø 74.9X79.0X1.5 (MF55)

ANTI-EXTRUSION RING, Ø 71.9X76.8X1.5 3

36

F73221856

F73221956

F73222056

CYLINDER SEAL Ø 45

CYLINDER SEAL Ø 50

CYLINDER SEAL Ø 55

3

37 701111 OR, Ø 10.78X2.62 6

38

F74100192

F74100292

F74100392

PISTON HEAD RING, Ø 45

PISTON HEAD RING, Ø 50

PISTON HEAD RING, Ø 55

3

39

90285000

F90286300

F90287300

SEAL RING, Ø 45.0X60.0X4.5/7.5 HP

SEAL RING, Ø 50.0X65.0X7.5/4.5 HP

SEAL RING, Ø 55.0X70.0X5.0/4.5 HP

3

40

F90284800

F90286500

F90287500

RESTOP RING, Ø 45

RESTOP RING, Ø 50

RESTOP RING, Ø 55

3

41

F73222170

F73222270

F73222370

CENTERING RING Ø 45

CENTERING RING Ø 50

CENTERING RING Ø 55

3

42 F73221691

F73221791

CENTERING HEAD BUSHING Ø 45-50

CENTERING HEAD BUSHING Ø 55 3

43 F90371000 OR, Ø 81.0X2.0 9

44

F73080056

F73080156

F73080256

BOTTOM RING Ø 45

BOTTOM RING Ø 50

BOTTOM RING Ø 55

3

45

F90284600

F90286000

F90287000

SEAL RING, Ø 45.0X53.0X5.5 LP

SEAL RING, Ø 50.0X58.0X5.5 LP

SEAL RING. Ø 55.0X63.0X5.5 LP

3

46 F99514200 SCREW M16X45 14

47 F99522500 SCREW M16X200 6

48 F99522200 SCREW M16X180 2

49 F96735500 WASHER Ø 16.0X65.0X1.0 3

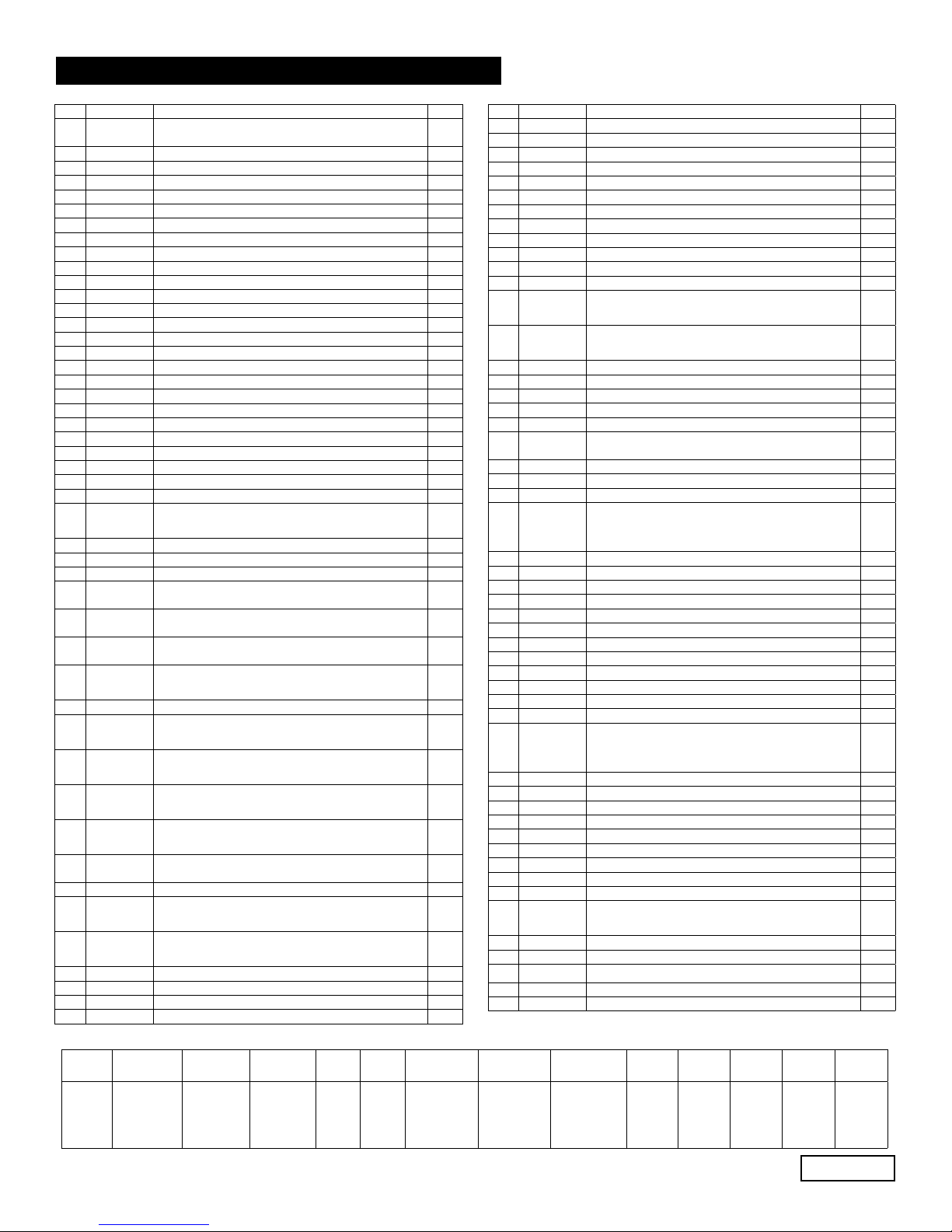

KIT

NUMBER

F2312 (MF45)

Plunger Pack.

F2313 (MF50)

Plunger Pack.

F2314 (MF55)

Plunger Pack.

F2142

Inlet

Valve

F2062

Outlet

Valve

F2315 (MF45)

Complete Seals

F2316 (MF50)

Complete Seals

F2317 (MF55)

Complete Seals

F2150

Conn. Rod

F2151

Conn. Rod

F2153

Conn. Rod

F2152

Mounting

Feet

F2189

Valve lifter

junction

Positions

Included

32, 33, 34,

35, 37, 39, 40,

43, 45

32, 33, 34,

35, 37, 39, 40,

43, 45

32, 33, 34,

35, 37, 39, 40,

43, 45

13 28

6, 7, 14, 15,

19, 21, 22, 32,

33, 34, 35, 37,

39, 40, 43, 45,

52, 54, 71, 80,

90, 93

6, 7, 14, 15,

19, 21, 22, 32,

33, 34, 35, 37,

39, 40, 43, 45,

52, 54, 71, 80,

90, 93

6, 7, 14, 15,

19, 21, 22, 32,

33, 34, 35, 37,

39, 40, 43, 45,

52, 54, 71, 80,

90, 93

63, 64 63, 64 63, 64 59, 99 101, 102,

103

Ref 310069 Rev. B

07-18