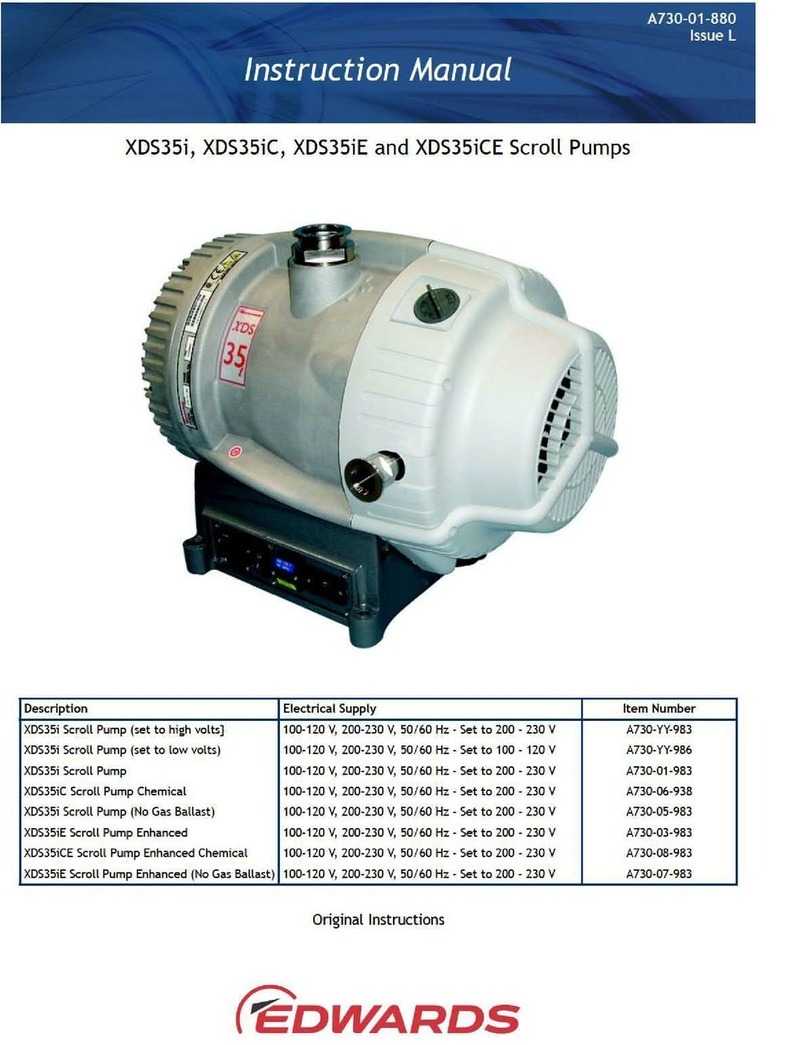

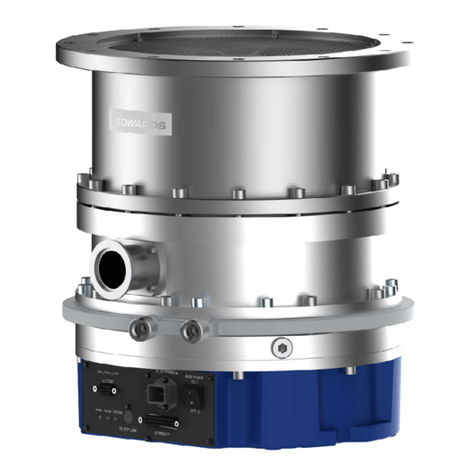

The pump has an NW40 (item 1) inlet and inlet strainer.

The pump mechanism is driven directly by a three‑phase electric motor. The motor is

controlled by a drive, which manages the supply of current to the motor in accordance

with operang condions and allows the pump to be connected to a single phase

supply. The voltage changeover switch beneath the voltage changeover switch cover

(item 8) must be set to the correct posion in accordance with the power supply being

used, refer to Connect the pump to the electrical supply on page 20.

The pump is designed to run from atmospheric pressure however, if the inlet pressure

exceeds 100 mbar for an extended period, the inverter may reduce the motor speed.

The pump will speed up again aer the pressure is reduced. Maximum rated connuous

operang pressure at 40 °C ambient is 40 mbar.

The enhanced pump versions (XDS35iE and 35iCE) are equipped with patented

technology which prevents over‑compression within the scroll mechanism at high

operaonal pressure and large throughput applicaons. Twin by‑pass valves release

suciently compressed gas directly to the pump exhaust, increasing pump eciency,

lowering power consumpon and enhancing pumping speed. Valve operaon occurs at

inlet pressures greater than 300 mbar, meaning the pump is tailored towards

applicaons which dwell at higher pressure. The eliminaon of over‑compression at high

operaonal pressure, reduces power consumpon and diminishes bearing loads,

extending bearing life. Consequently, the enhanced versions are capable of operaon

without limitaons to both the size of vacuum chamber, or the frequency of pump down

on cyclic dues.

Note:

The pump modicaons within the enhanced version have a small adverse eect on the

ulmate vacuum achieved however, the pump has a larger tolerance to operang

altude and ambient temperature.

The pump is air‑cooled by a fan (item 3) mounted at the opposite end to the motor. The

fan will connue to run for one minute aer the pump is switched o. The pump

incorporates a thermal protecon device that will stop the motor in the event of thermal

overload, for example, high ambient temperature. The pump will restart aer cooling

down.

2.4 Gas ballast control

To pump high vapour loads, gas ballast can be delivered into the pump to prevent

condensaon of the vapour carried by the pumped gases.

Air can be introduced to the low vacuum stages through the gas ballast control (item 2)

(not ed on the No Gas Ballast variant). Alternavely, an inert gas such as nitrogen can

be supplied through a suitable external valve and by using the appropriate adaptor,

available as an accessory, refer to Gas ballast adaptor on page 34.

The gas ballast control has three posions:

▪Closed (posion '0')

▪Low ow (posion 'I')

▪High ow (posion 'II')

Page 10

A73001880_M - Introducon