2 3A8478A

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Requirements . . . . . . . . . . . . . . . . . . . . . 7

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Install Vented Oil Cap Before Using Equipment . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

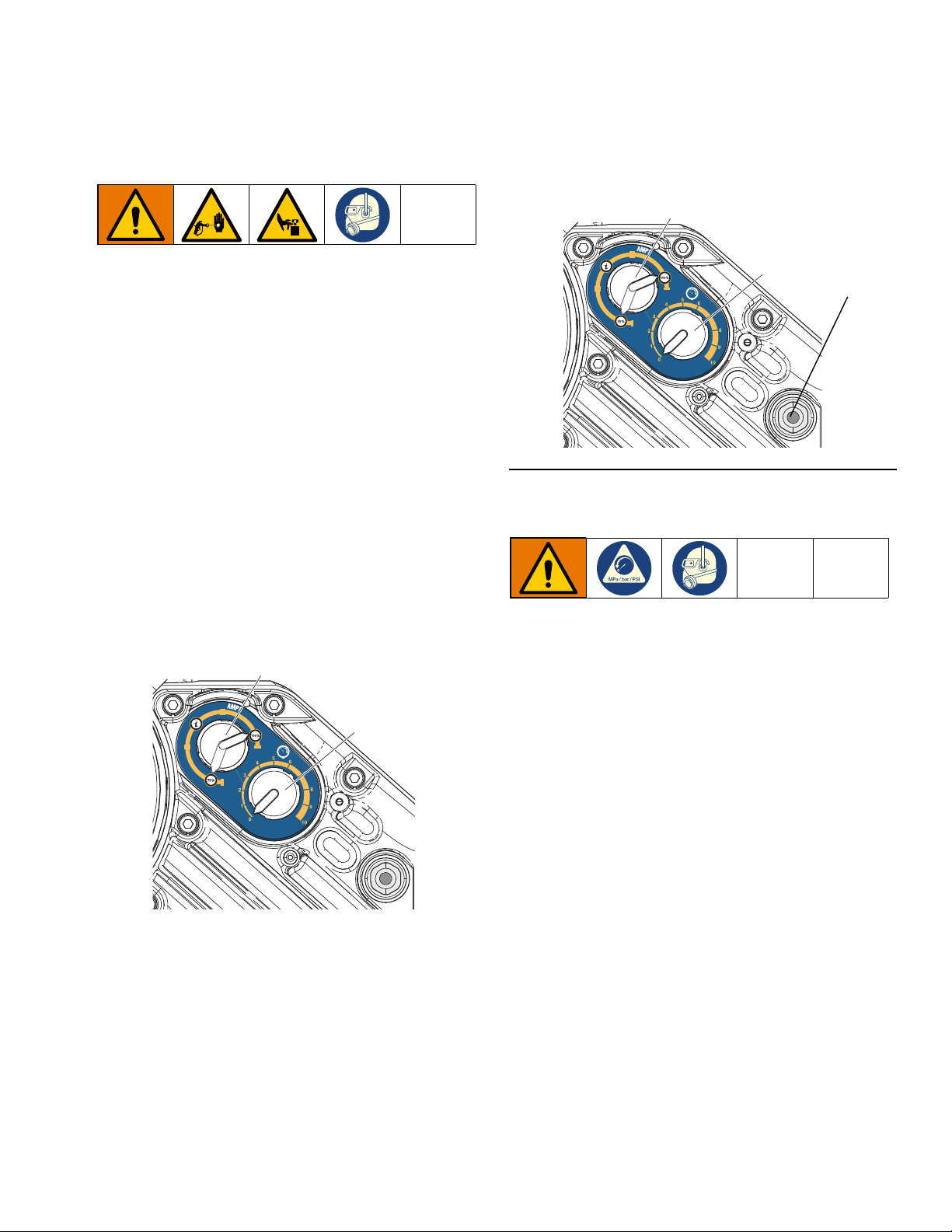

Driver Operation . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preventative Maintenance Schedule . . . . . . . . 11

Change the Oil . . . . . . . . . . . . . . . . . . . . . . . . . 11

Check Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bearing Pre-Load . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Error Code Troubleshooting . . . . . . . . . . . . . . . 12

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Error Codes Table . . . . . . . . . . . . . . . . . . . . . . . 12

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replace Output Seal Cartridge . . . . . . . . . . . . . 14

Replace Fan Fuses . . . . . . . . . . . . . . . . . . . . . . 14

Remove Fan Shroud . . . . . . . . . . . . . . . . . . . . . 15

Disconnect Fan Wires . . . . . . . . . . . . . . . . . . . . 15

Reinstall Fan Wires . . . . . . . . . . . . . . . . . . . . . . 16

Replace Electronics Cover . . . . . . . . . . . . . . . . 16

Replace Stroke Position Sensor . . . . . . . . . . . . 19

Replace Encoder . . . . . . . . . . . . . . . . . . . . . . . . 20

Repair Token Cable . . . . . . . . . . . . . . . . . . . . . . 22

Software Update Procedure . . . . . . . . . . . . . . . 23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electric Driver . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts List - Electric Driver (25P291) . . . . . . . . . 25

Mounting Hole Pattern . . . . . . . . . . . . . . . . . . . . 26

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Technical Specifications . . . . . . . . . . . . . . . . . . . . 29

California Proposition 65 . . . . . . . . . . . . . . . . . . . 29

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . 29

End of Product Life . . . . . . . . . . . . . . . . . . . . . . 29

Graco Extended Warranty . . . . . . . . . . . . . . . . . . . 30

Related Manuals

Manuals are available at www.graco.com.

Models

Manual in

English

Description

3A8477 E70/E60 King Sprayer Manual

Part Series Description

25P291 B King Driver, Non-Haz Loc