Troubleshooting

10 333233D

4 Deviation High Temperature

The temperature of the system is near the maximum operation temperature. The

performance has been reduced to prevent the sprayer from completely shutting

down.

• Check fan operation. Clean fan and driver housing. Verify fuses are intact in junc-

tion box.

• Reduce pressure, duty cycle, or gun tip size.

• Move unit to a cooler location.

5 Alarm Motor Temperature Fault

Motor is running too hot. Allow unit to cool.

• Check fan operation. Clean fan and driver housing. Verify fuses are intact in junc-

tion box.

• Reduce pressure, duty cycle, or gun tip size.

• Move unit to a cooler location.

6 Alarm Board Temperature Fault

The control board is running too hot. Allow unit to cool.

• Check fan operation. Clean fan and driver housing. Verify fuses are intact in junc-

tion box.

• Reduce pressure, duty cycle, or gun tip size.

• Move unit to a cooler location.

7 Alarm Encoder Calibration Error

• Cycle power and check status indicator to see if error is still active.

• Calibrate the encoder (see page 17).

• Contact your Graco distributor or Tech Service for more information.

8 Alarm Encoder Error

• Cycle power and check the status indicator to see if the error is still active.

• Verify that the encoder cable is connected securely.

• The encoder may need to be replaced.

• Contact your Graco distributor or Tech Service for more information.

9 Alarm Software Versions Do Not Match

• Obtain software update token and follow Software Update procedure

(contact your Graco distributor or Tech Service for more information).

10 Alarm Circuit Board Communication Failure

• Cycle power and check status indicator to see if error is still active.

• Contact your Graco distributor or Tech Service for more information.

11 Alarm Internal Circuit Board Hardware Failure

• Cycle power and check status indicator to see if error is still active.

• Contact your Graco distributor or Tech Service for more information.

12, 13 Alarm Internal Software Error

• Cycle power and check status indicator to see if error is still active.

• Contact your Graco distributor or Tech Service for more information.

Fast Flash Deviation See Power Saving Mode, page 9.

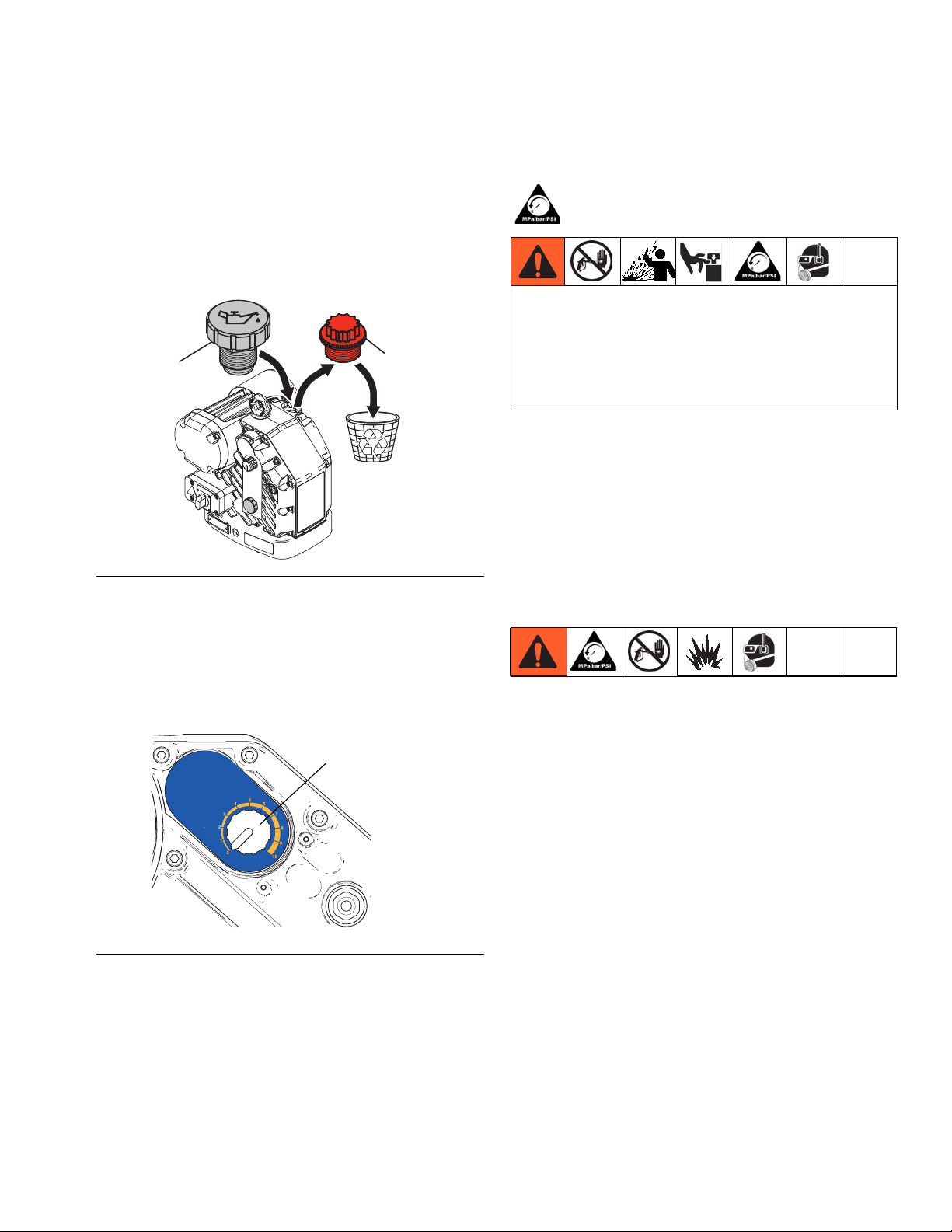

Blink Code Error Type Troubleshooting Steps