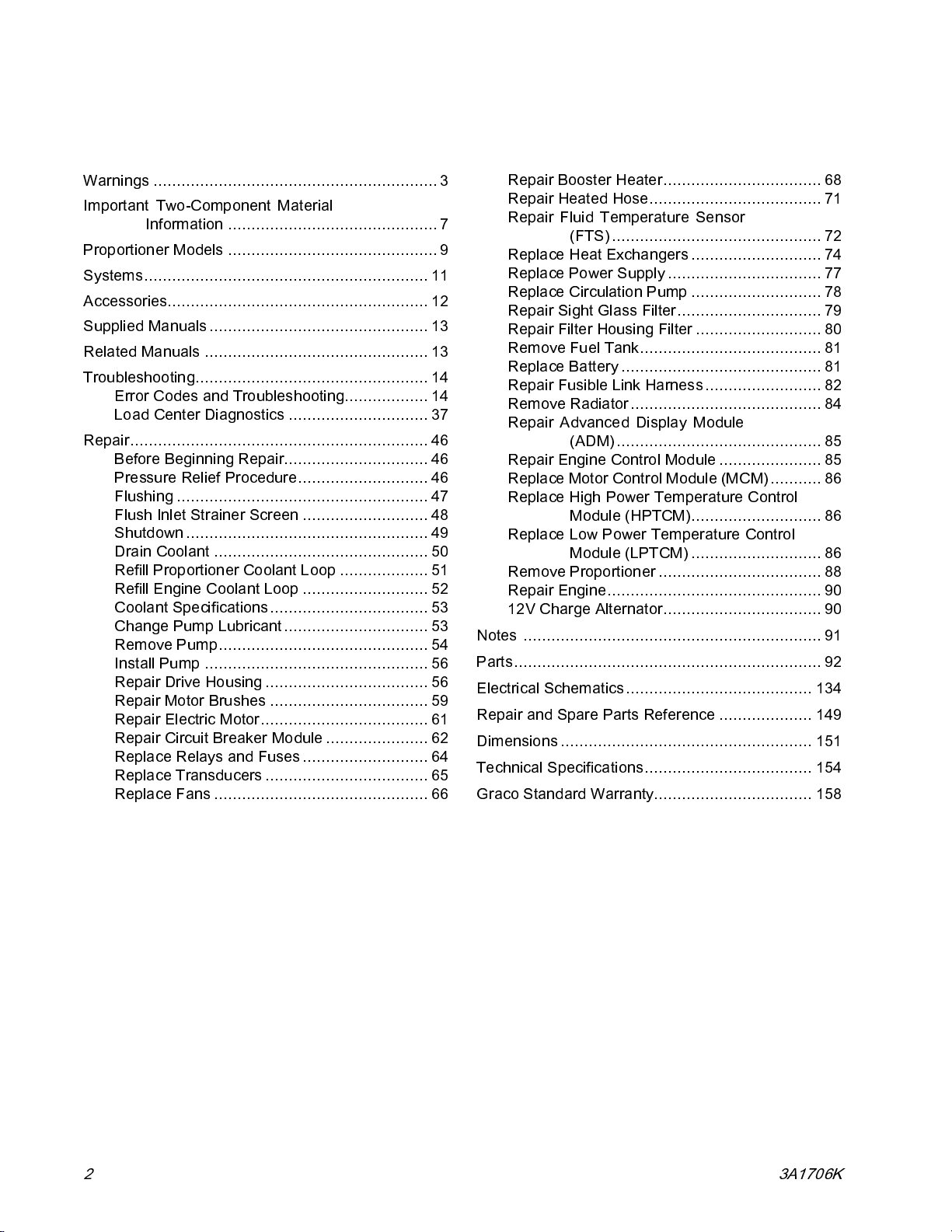

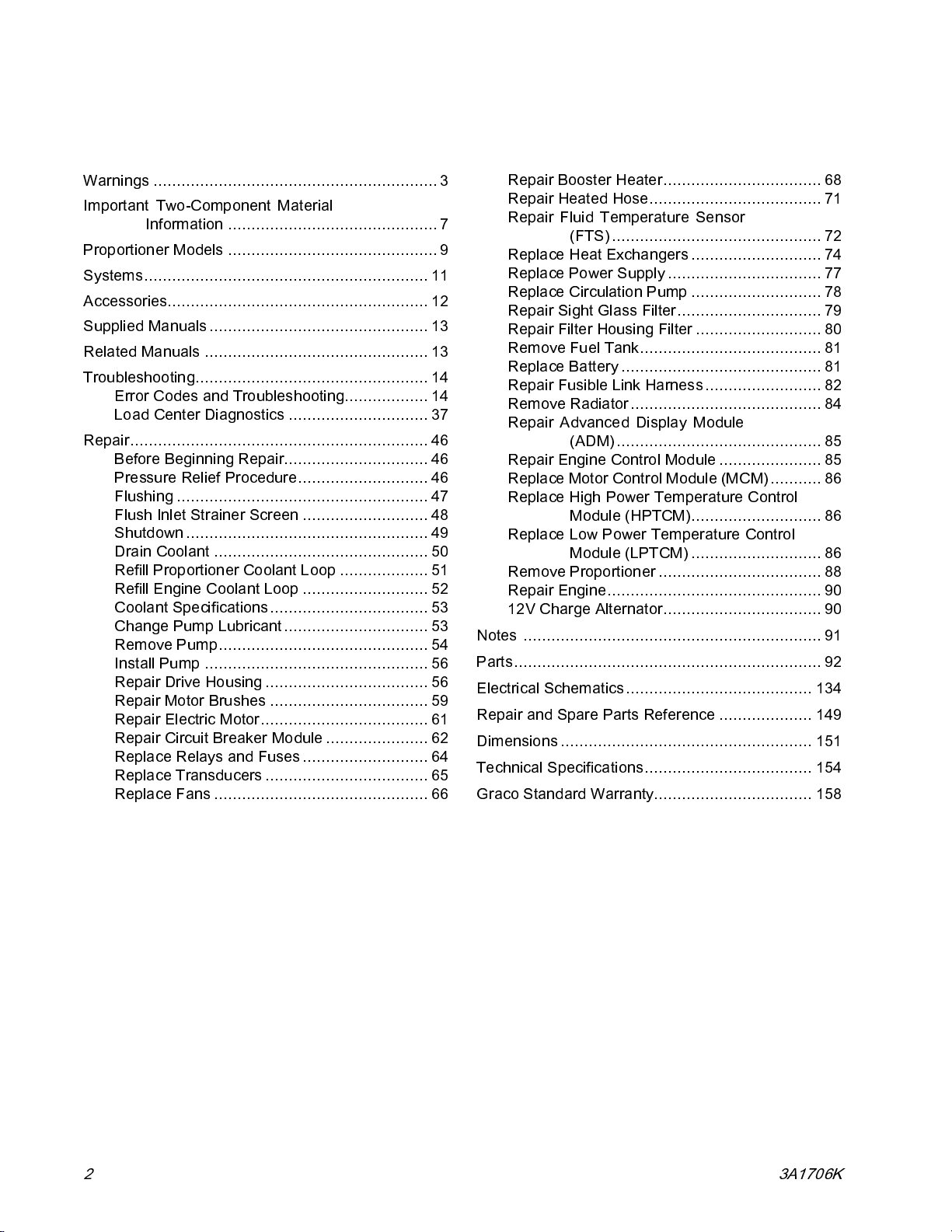

Contents

Warnings .............................................................3

Important Two-Component Material

Information .............................................7

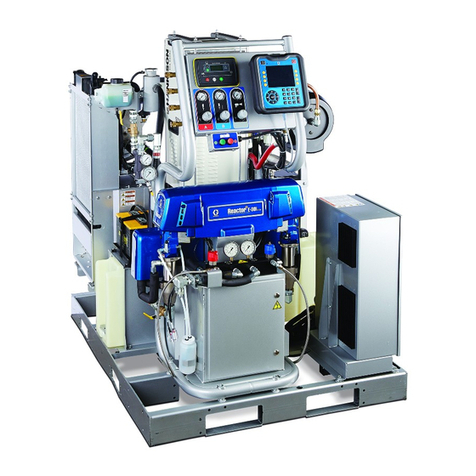

Proportioner Models .............................................9

S stems............................................................. 11

Accessories........................................................ 12

Supplied Manuals............................................... 13

Related Manuals ................................................ 13

Troubleshooting.................................................. 14

Error Codes and Troubleshooting.................. 14

Load Center Diagnostics .............................. 37

Repair................................................................ 46

Before Beginning Repair............................... 46

Pressure Relief Procedure............................ 46

Flushing ...................................................... 47

Flush Inlet Strainer Screen ........................... 48

Shutdown.................................................... 49

Drain Coolant .............................................. 50

Refill Proportioner Coolant Loop ................... 51

Refill Engine Coolant Loop ........................... 52

Coolant Specifications.................................. 53

Change Pump Lubricant............................... 53

Remove Pump............................................. 54

Install Pump ................................................ 56

Repair Drive Housing ................................... 56

Repair Motor Brushes .................................. 59

Repair Electric Motor.................................... 61

Repair Circuit Breaker Module ...................... 62

Replace Rela s and Fuses........................... 64

Replace Transducers ................................... 65

Replace Fans .............................................. 66

Repair Booster Heater.................................. 68

Repair Heated Hose..................................... 71

Repair Fluid Temperature Sensor

(FTS)............................................. 72

Replace Heat Exchangers ............................ 74

Replace Power Suppl ................................. 77

Replace Circulation Pump ............................ 78

Repair Sight Glass Filter............................... 79

Repair Filter Housing Filter ........................... 80

Remove Fuel Tank....................................... 81

Replace Batter ........................................... 81

Repair Fusible Link Harness......................... 82

Remove Radiator......................................... 84

Repair Advanced Displa Module

(ADM)............................................ 85

Repair Engine Control Module ...................... 85

Replace Motor Control Module (MCM)........... 86

Replace High Power Temperature Control

Module (HPTCM)............................ 86

Replace Low Power Temperature Control

Module (LPTCM)............................ 86

Remove Proportioner ................................... 88

Repair Engine.............................................. 90

12V Charge Alternator.................................. 90

Notes ................................................................ 91

Parts.................................................................. 92

Electrical Schematics........................................ 134

Repair and Spare Parts Reference .................... 149

Dimensions...................................................... 151

Technical Specifications.................................... 154

Graco Standard Warrant .................................. 158

23A1706K