Safety Precautions

CAUTION

Do not operate BHE beyond its specified conditions (temperature, flow rate, and pressure).

Deformation of heat transfer plates and leakage from BHE might be caused and can't be

reached the required performance.

Avoid any pressure shock to BHE.

The pressure shock can cause deformation or cracking or leakage of BHE.

Do not install on any heat-generating equipment.

BHE might be deformed by heat, and can't be reached the required performance.

Use only the cleaning chemicals recommended in Section 9 "Maintenance" (on page 10).

Any cleaning chemicals except the recommended may corrode BHE.

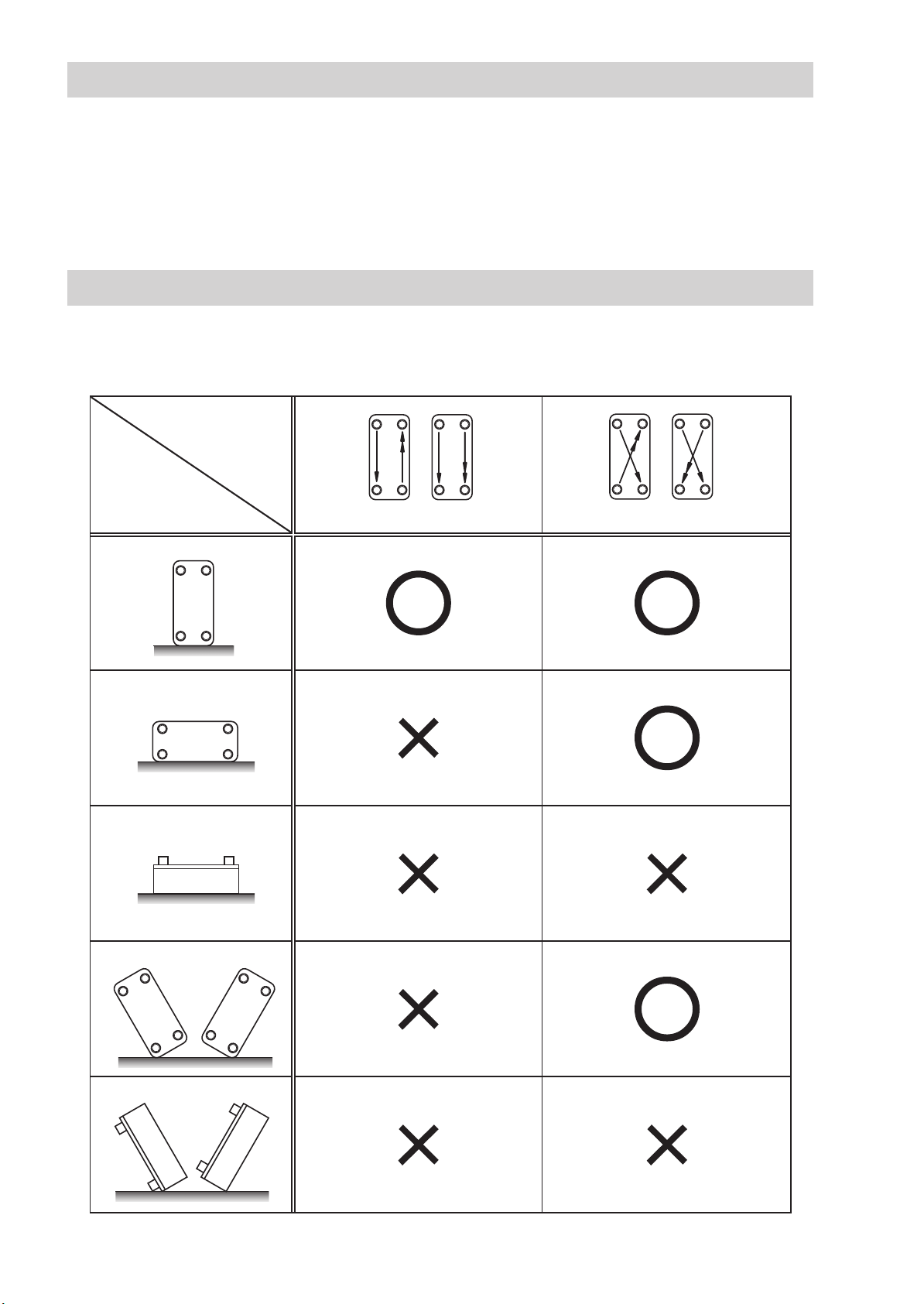

BHE should be used vertical installation for evaporator or condenser.

Sufficient performance may not be obtained other than vertical installation.

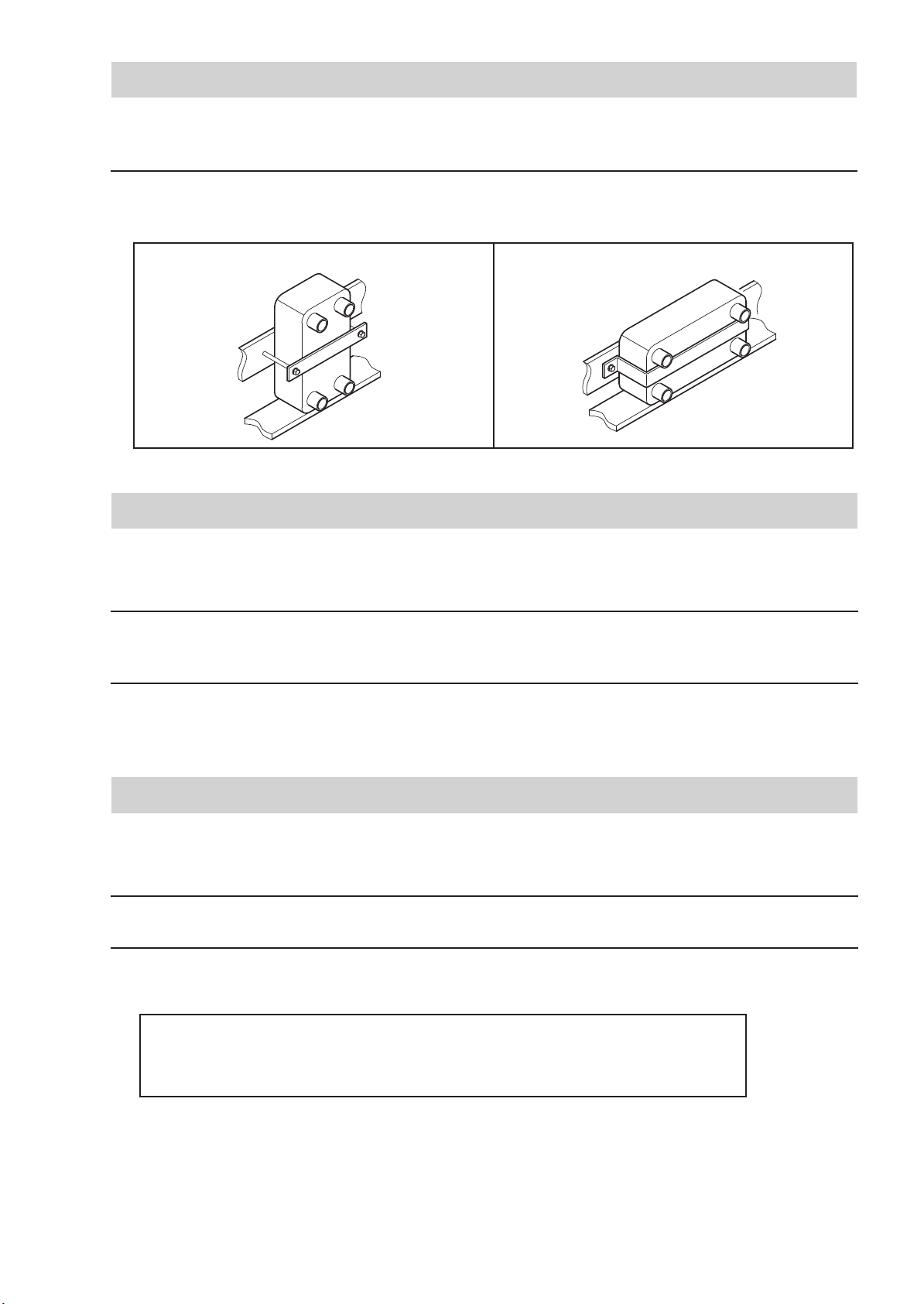

Install the control devices such as a solenoid valve at the flow channel inlet side.

If installing them at the outlet side, BHE may be damaged by pressure shock.

Install a strainer of mesh size 10 to 20 at the inlet side of BHE.

It is effective to prevent the clogging of BHE.

To prevent the fluid from freezing between the heat transfer plates.

• When starting operation, flow the hot fluid first, and then the cold fluid.

• When stopping operation, stop the cold fluid first, and then the hot fluid.

Do not use the cleaning chemicals frequently.

Use it only in case of decreasing the performance.

Frequent use may cause corrosion of BHE.

In case of using BHE as a heater, watch/control the operating condition to avoid the

scorching on the plates by:

• When starting operation, flow the cold fluid first, and then the hot fluid.

• When stopping operation, stop the hot fluid first, and then the cold fluid.

Avoid any load on the nozzles of BHE. The nozzles can be damaged by the load.

BHE itself or BHE nozzle might be damaged by a load from the piping/the control devices or

a load by thermal expansion of piping.

Support the piping so as to offset the load.

The durability of BHE can drop significantly in the operating conditions as shown below.

Contact Hisaka Works to check that BHE can be used.

•

Operation where the temperature difference of the hot fluid inlet and cold fluid inlet exceeds 80°C�

• Operation where there are frequent pressure fluctuations (pressure shock)

Avoid any vibration on BHE.

BHE itself or BHE nozzle might be damaged by a vibration. When installing and fixing BHE,

take appropriate measures such as providing support or suppressing the vibration.

4