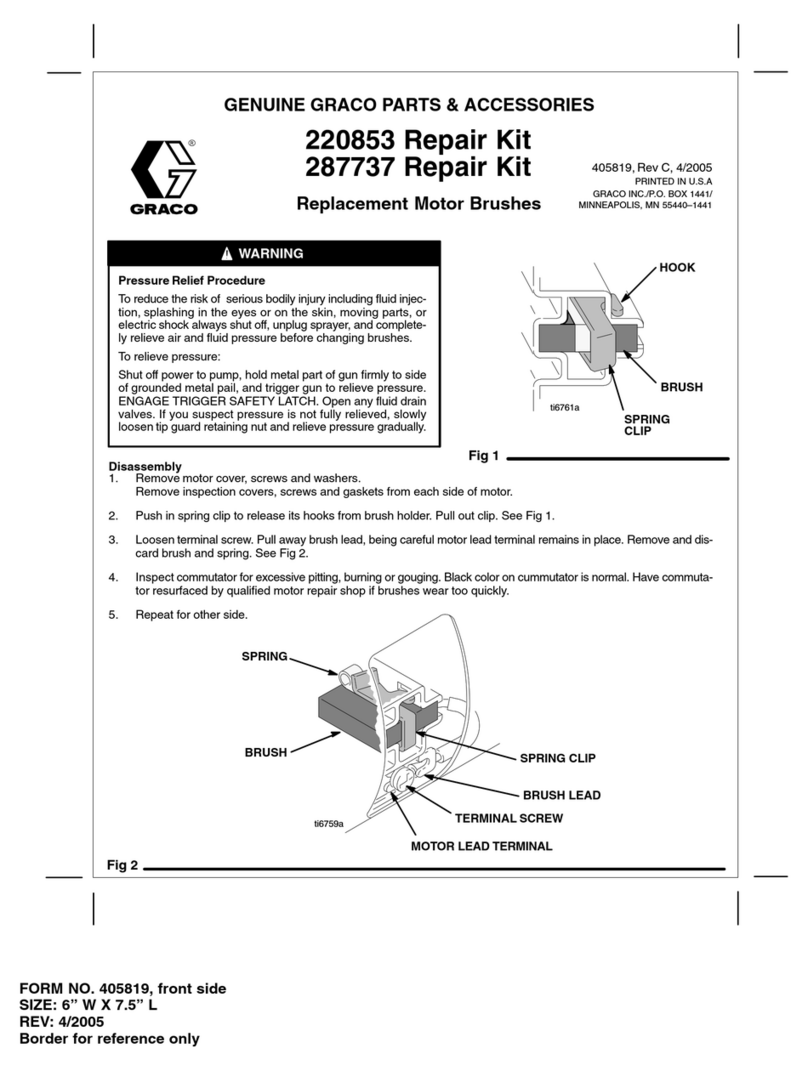

Repair

Disassemble Disassemble

DisassembleAir Air

AirCylinder Cylinder

CylinderCap Cap

Cap

1.PerformthePressureReliefprocedureandturn

offfacilityairtothesystem.

2.Disconnectthebracket(101)fromtheaircylinder

pistonrod:

a.Ensurethatthepumpisinasafeposition

thatwillpreventtippingorprovideameans

ofsupport.

b.Disconnecttheairsupplyhosetothepump

attheaircontroller.

c.Disconnecttheairhoseatbothairttings

(210)ontheaircylinder.

d.Removethenut(109)andwasher(108).

e.Withoutdisconnectingthepumpfromthe

bracket,liftthebracketoffoftheaircylinder

pistonrodandsetaside.

3.Removetheaircylinderendcap(15):

a.Removethescrews(19)andwashers(17).

b.Lifttheendcapoffoftheaircylinderand

carefullymovethecappastthealignment

pin(6)ontheaircylinderpistonrod.

4.Examinethecapsealandringsfordamageor

wear.Replaceifnecessary.

Air Air

AirCylinder Cylinder

CylinderPiston Piston

PistonComponent Component

ComponentRepair Repair

Repair

NOTICE NOTICE

NOTICE

Donottilttheaircylinderpistonrodtooneside

whenremovingitfromtheaircylinderorwhen

installingit.Suchmovementcandamagethe

pistonorinsidesurfaceoftheaircylinder.

NOTE: NOTE:

NOTE:Somecomponentswillnotpassthealignment

pinonthetopoftheaircylinderpistonrodandmust

beremovedfromthebottomofthepistonrod.The

alignmentpinshouldnotberemovedunlessitis

damaged.

Partpositionsandorientation

PartDescription

RamTopBearing(4)

Seal(7)•u-cuplipsfaceindirectionofpiston

assembly

•inneratalignswithatonair

cylinderpistonrod

•ring(13)locatedabovetheseal

Bearing(8)•alignmentslotmustbeattop

toallowengagingalignmentpin

insideramtopbearing(4)

•retainer(9)locatedbelowthe

bearing(8)holdingitintoramtop

bearing(4)

Piston(3)

O-ring(5)•locatedinholeincenterofpiston

(3)

1.Removingtheaircylinderpistonrodassembly:

a.Removethetopaircylindertting(23).

b.Removetheretainingring(16)frominside

theaircylinder.

c.Lifttheaircylinderpistonrodassemblyout

oftheaircylinder.

d.Examineallcomponentsforwearordamage

andreplaceasneeded.Refertothe

appropriateproceduresthatfollowtorepair

theaffectedcomponent(s).

2.Toremovetheramtopbearingassembly

componentsorthepistonassemblycomponents:

a.Usenon-marringtoolstograspandholdthe

aircylinderpistonrod(2)andremovethenut

(12)andwasher(11).

b.Slidethedesiredassemblyoffoftheair

cylinderpistonrodforrepair.

3.Installingtheaircylinderpistonrodassembly:

a.Examinetheinterioroftheaircylinder.There

shouldbeacoatingofgreaseovertheentire

innersurface.Applyfoodsafegreasetoany

areasthatneedapplication.

b.Insertthepiston(3)endofaircylinderpiston

rodassemblyintotheaircylinderandlower

untilthealignmentpinontheupperram

bearing(4)canbepositionedinthesloton

theaircylinder.

NOTE: NOTE:

NOTE:Ensurethattheretainingringgroove

isfreeofdebrisandlubricantsothatthe

retainingringwillseatfully.

c.Installtheretainingring(16)intheair

cylinder.

103A5401C