8 306-726

Operation

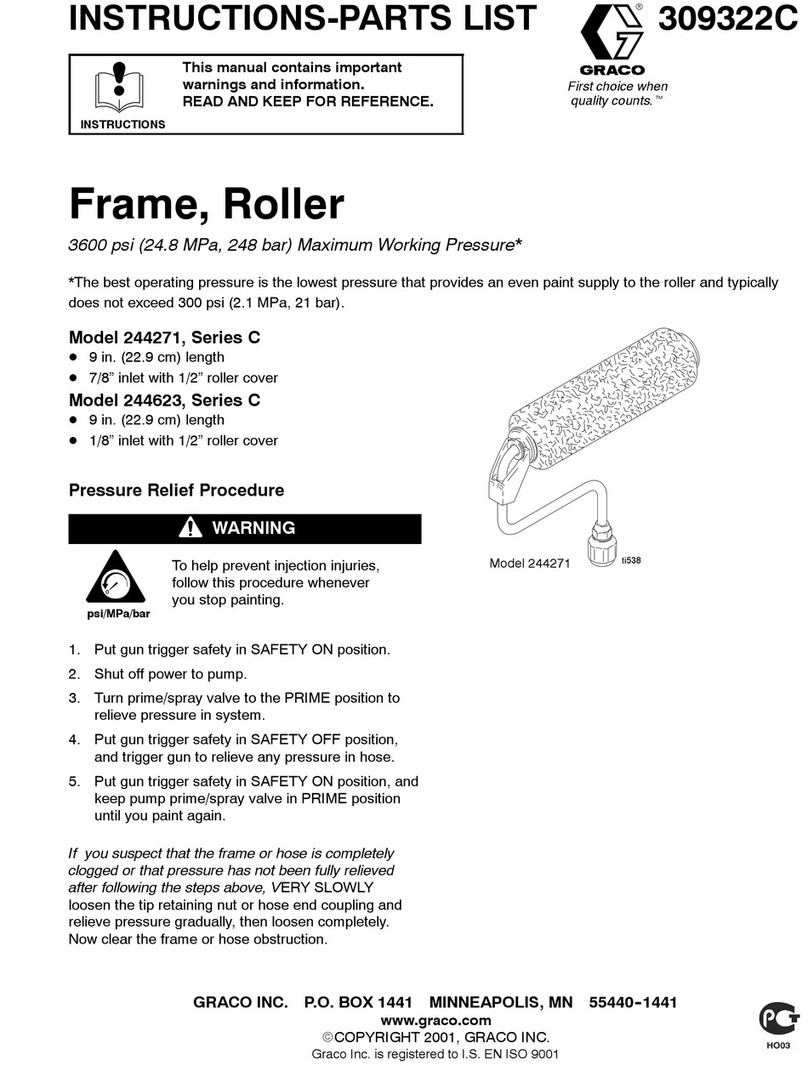

Pressure Relief Procedure

With the Evenflo control, its bypass valve, and the

pump Relax-A-Valve properly set, fluid pressure is

relieved from the pump and hose each time you re-

lease the gun trigger. Always engage the gun trigger

safety when you stop spraying. To relieve air pressure,

close the Evenflo regulators and open the bleed-type

master air valve.

WARNING

INJECTION HAZARD

If you suspect that the Evenflo system is

not properly set, or that pressure is not

fully relieved, the system pressure must

be manually relieved to prevent the system from

starting or spraying accidentally. Fluid under high

pressure can be injected through the skin and

cause serious injury. To reduce the risk of an injury

from injection, splashing fluid, or moving parts, fol-

low the Pressure Relief Procedure whenever you:

Dare instructed to relieve the pressure,

Dstop spraying,

Dcheck or service any of the system equipment,

Dor install or clean the spray tips.

1. Engage the spray gun or dispensing valve safety

latch.

2. Close the pump air regulator.

3. Close the master bleed-type air valve (required).

4. Disengage the gun or dispensing valve safety

latch.

5. Hold a metal part of the gun/valve firmly to a

grounded metal waste container and trigger to

relieve fluid pressure.

6. Engage the safety latch again.

7. Open the pump drain valve (required in your

system), having a container to catch the drainage.

NOTE: If your pump has a Relax-A-Valve set in the

automatic position, step 7 is not necessary.

8. Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, very slowly loosen the

tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely. Now clear

the tip or hose.

WARNING

Never operate the pump with the air motor plate

removed. Moving parts in the piston can pinch or

amputate fingers.

Startup

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

The pump was tested in oil, and some oil was left in

the pump to protect it from corrosion. if the oil will

contaminate the fluid your are pumping, flush it out.

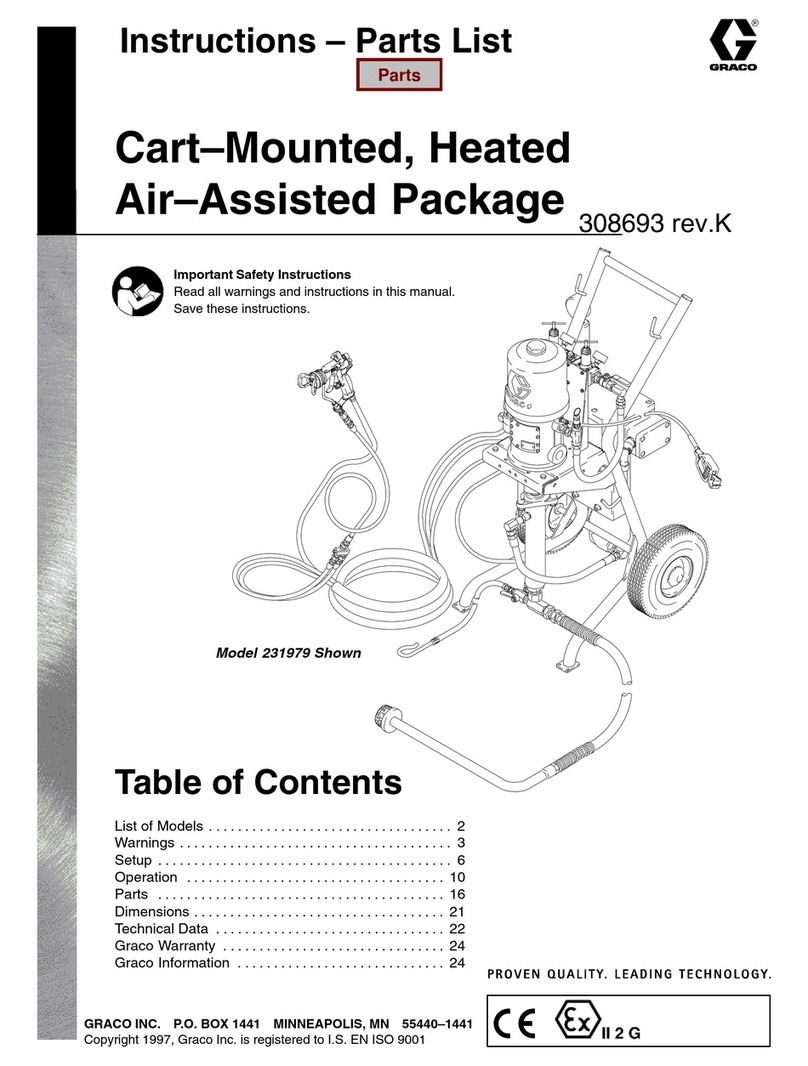

To start the pump, close the fluid drain valve (H). Open

the bleed-type master air valves (A). Holding a metal

part of the spray gun/dispensing valve firmly against

the side of a grounded metal pail, hold the trigger open

while slowly opening the air regulator (E), Run the

pump slowly until all air is purged from the gun/valve.

Release the trigger and engage the safety latch (if

applicable).

Use the air regulator (E) to control fluid pressure and

pump speed. Always use the lowest pressure neces-

sary to get the desired results. Higher pressures cause

premature pump wear and spray tip wear, and usually

do not improve the spray pattern.

WARNING

To reduce the risk of overpressurizing your system,

which could result in component rupture and cause

serious injury, never exceed the maximum working

pressure of the lowest rated component in your

system. Lowering the air pressure to the motor will

proportionately lower the fluid outlet pressure from

the pump. Refer to the Technical Data on page 16

for the maximum air and fluid working pressure of

this pump.