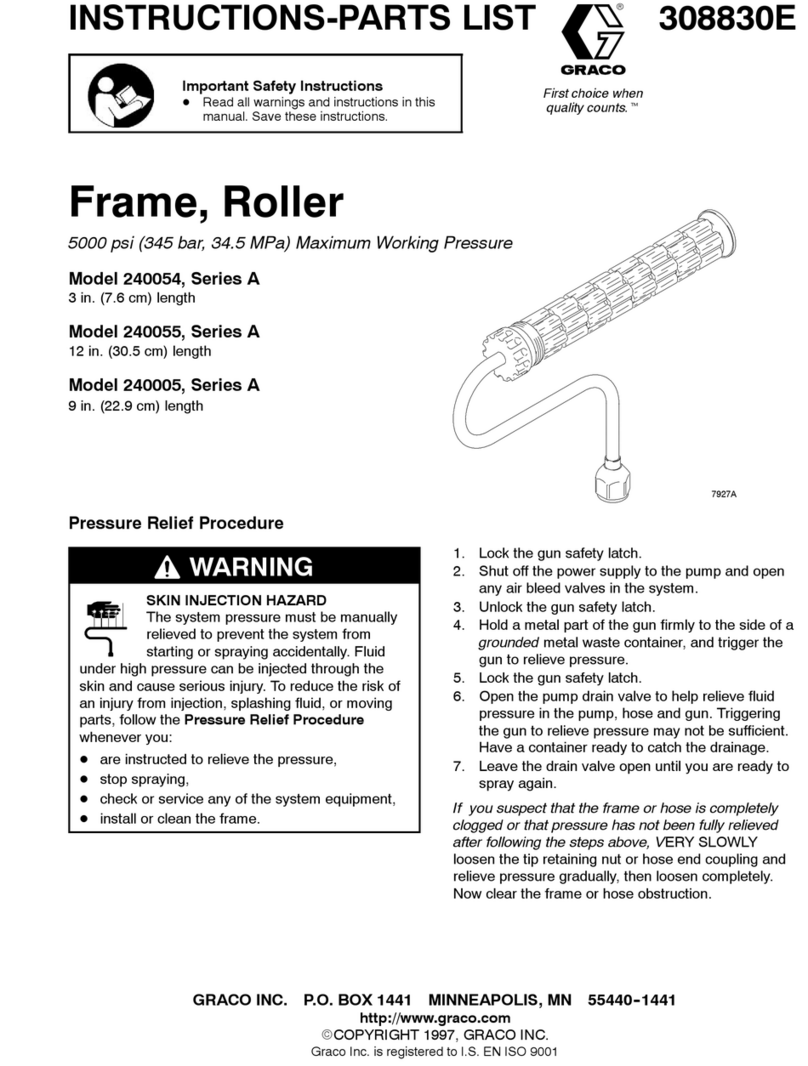

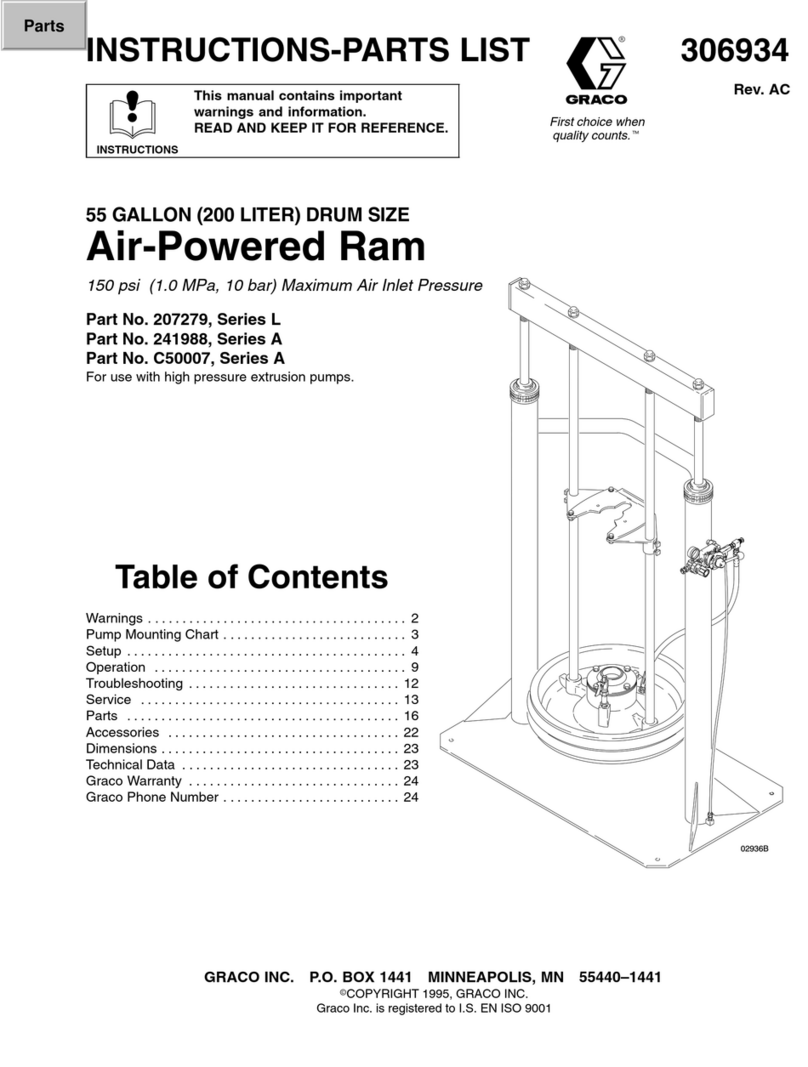

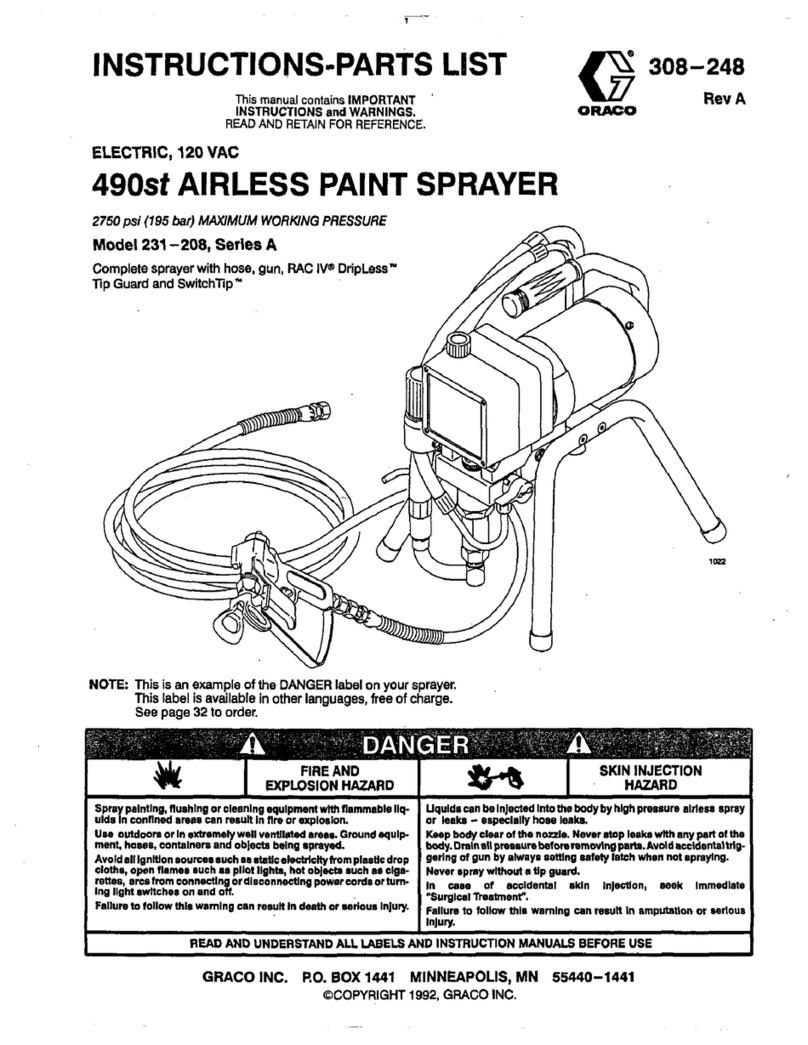

5. Pull plug out of electrical outlet, put a can under filter

drain valve and slowly open valve to release pressure.

Unscrew filter bowl from the outlet filter and check

to see that screen is clean. Reassemble bowl, hand

tight only. See Fig 2.

Hand-tight only)

6. If you are going to use latex paint or any other water

base material, flush unit with water to completely

remove mineral spirits.

ALVE

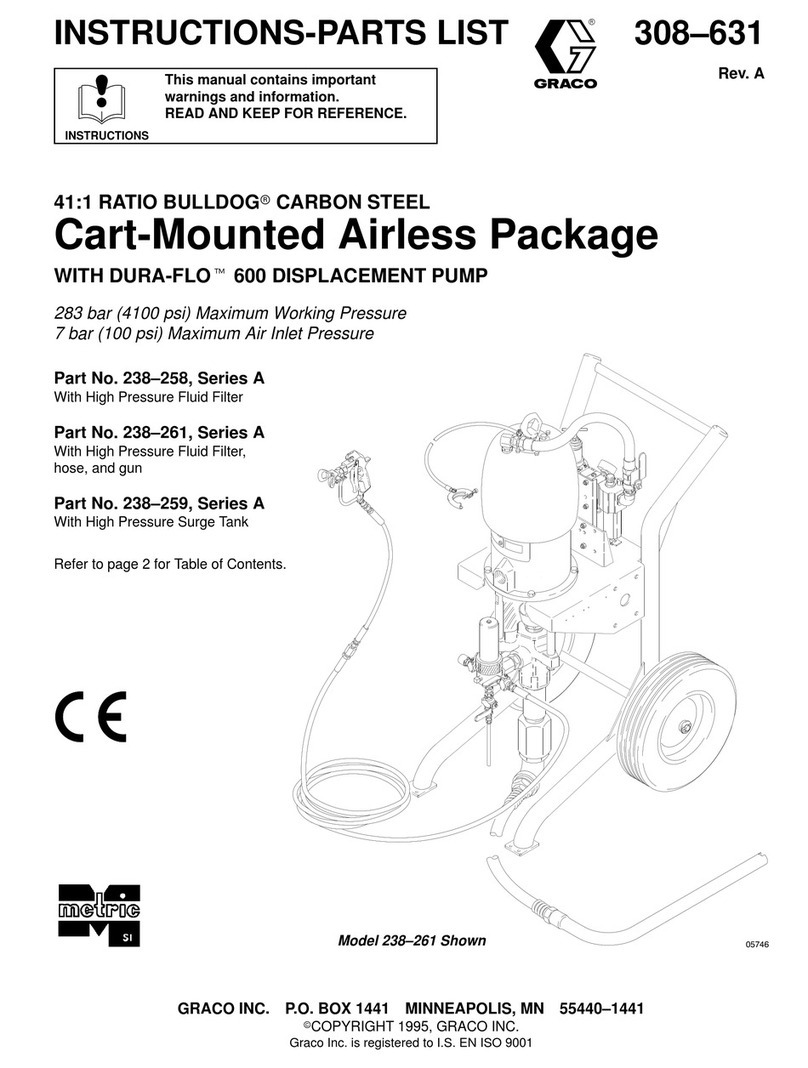

Fill Wetcup

Pour Grace Throat Seal Liquid (TSL) supplied, into wet-

cup until l/3 full. See Fig 3. Plug cord into outlet.

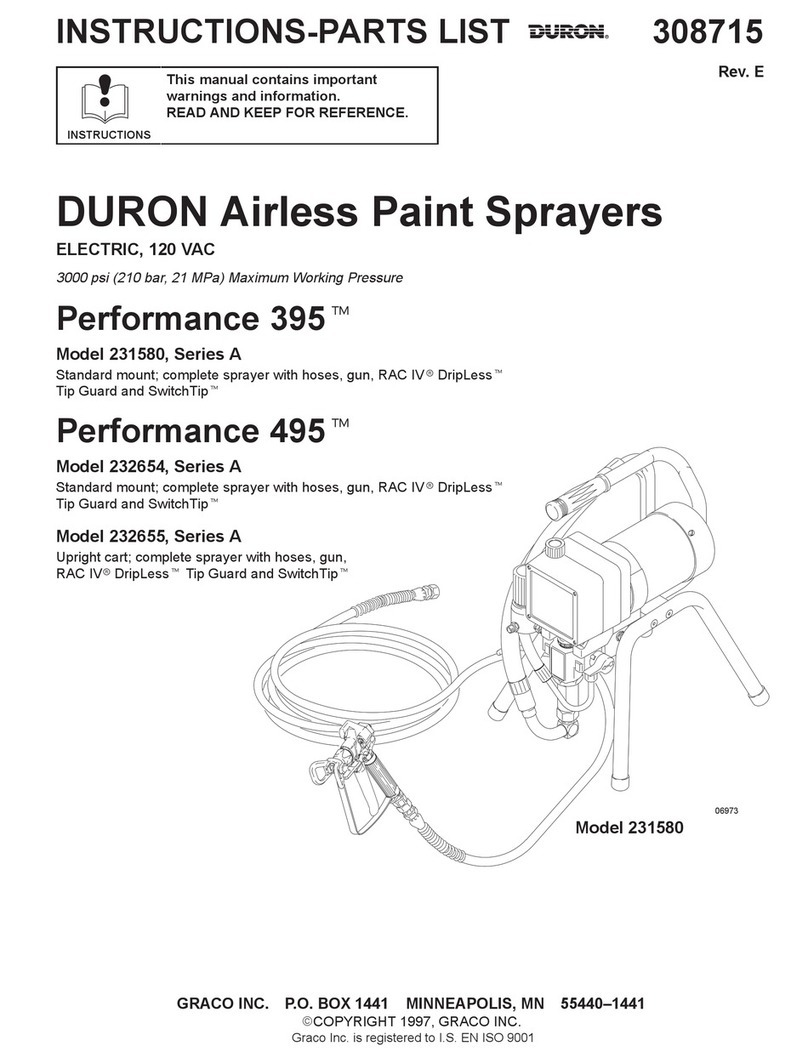

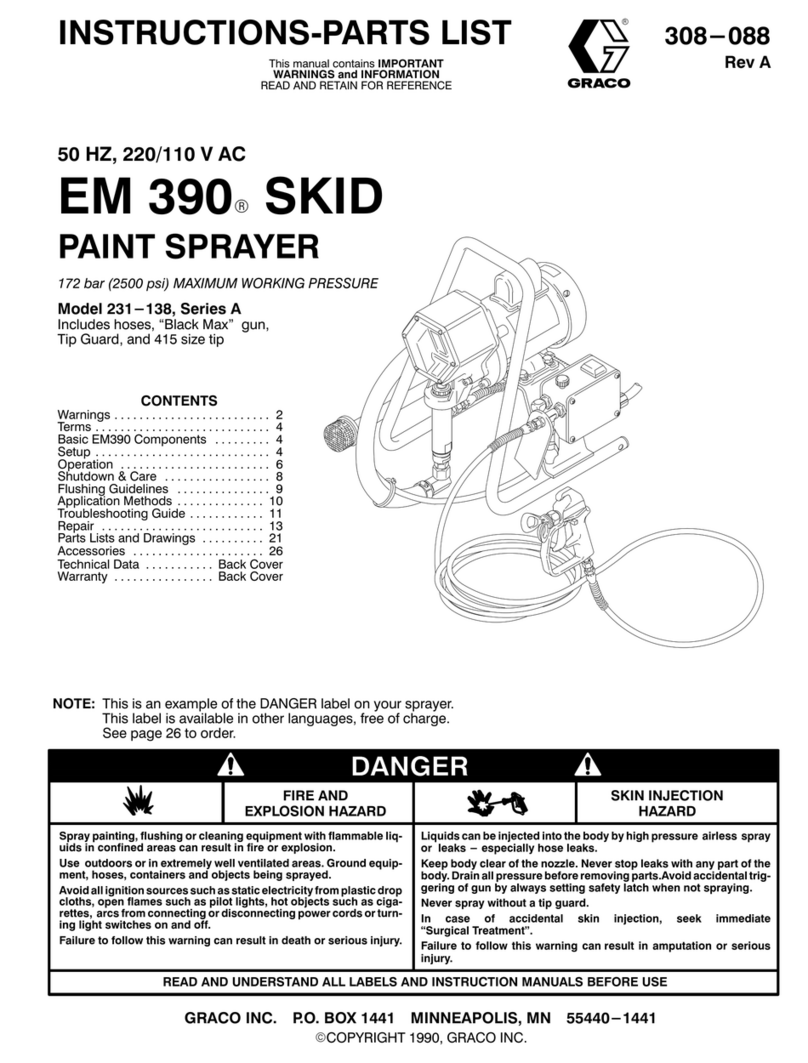

Fig 2

Mix Paint, Adjust Pressure and Spray

Prepare paint as instructed by manufacturer. Also see

instruction manual 306-997.

Put paint suction tube into pail of paint. Do not install

spray tip yet. Squeeze gun trigger, turn the unit on, and

let it run until all air is forced out of system. To avoid in-

troducing more air into the fluid line, always add paint

to original pail rather than changing pails.

NOTE: If paint is thick and hard to prime, first

remove strainer from suction tube, then

prime unit with water or compatible solvent.

When primed, turn unit OFF, plug immersed

end of suction tube with one finger and

transfer it into pail of thick paint. This keeps

air out of pump for more positive priming.

Replace strainer.

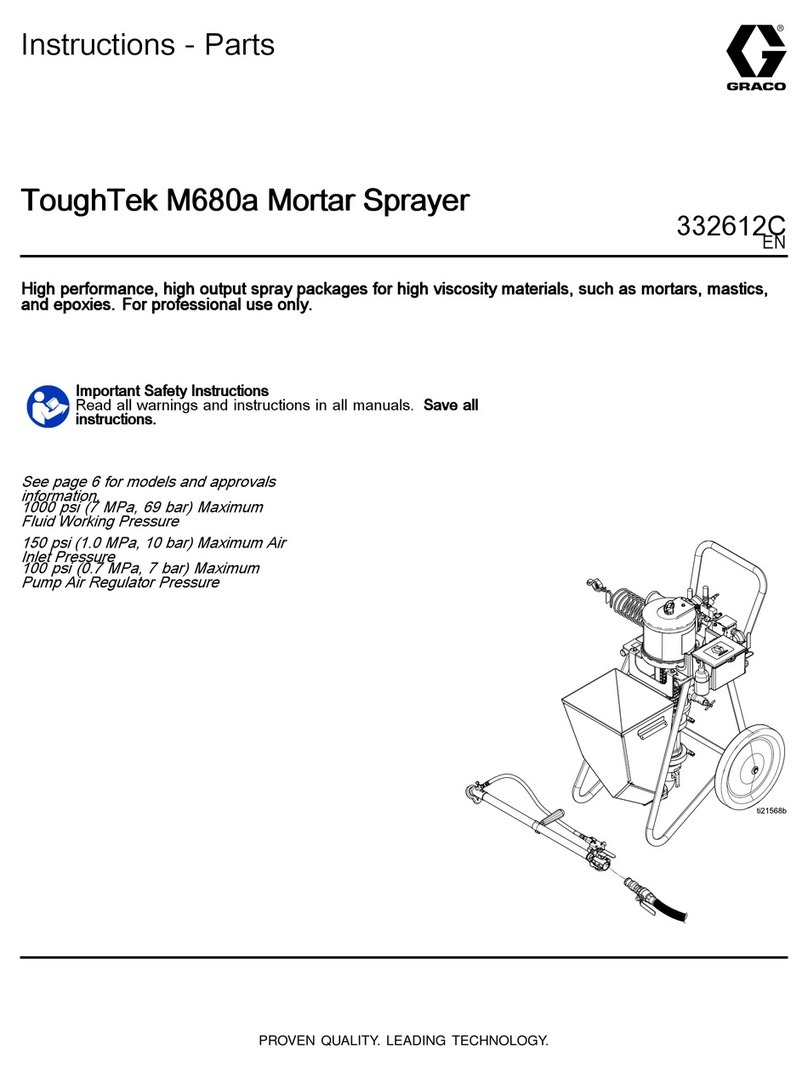

Fig 3

Unplug unit, relieve pressure acording to Pressure Relief

Procedure on page 3, and install Reverse-A-Clean III

spray housing with tip installed (see instruction manual

307-321) on gun. Adjust spray pressure to the lowest

pressure needed for satisfactory operation and spray a

test area to check spray pattern. Refer to instruction

manual 306-997 for spraying technique. For further in-

formation on tip selection, see instruction manual

307-321.

workday of week. If you are using paint that will dry

overnight, flush daily at shutdown.

NOTE: If pump fails to shut off with solvent in it, in-

take

valve

may be obstructed. Relieve

pressure according to Pressure Relief Pro- a

cedure on page 3, remove and clean as in-

structed on page 6 and reassemble while

parts are wet. Then finish flushing.

Relieve pressure according to Pressure Relief Procedure For very short shutoff periods, relieve pressure accord-

on page 3 and clean out front of tip frequently during ing to Pressure Relief Procedure on page 3, and leave

day’s operation with a solvent soaked brush, to keep suction tube in paint and clean spray tip. Follow safety

material from building up and clogging tip. procedure on page 2 when removing the tip.

Cleaning A Clogged Tip

If spray tip clogs while spraying, release spray

gun trigger and turn Reverse-A-Clean handle 180”.

Disengage safety and trigger gun. Fluid pressure should

force obstruction from spray tip. Release trigger,

engage

trigger safety,

return handle to original position

and resume spraying.

Always wrap hose around hose brackets when storing

unit, even if only overnight, to help protect hose from

damage. Suction hose and tube can be routed around

rear bracket and tube end slipped under front bracket.

Don’t store unit with water in it. Even for overnight

storage you should fill the unit with mineral spirits. This

prevents rust and greatly extends the life of the unit.

If fluid pressure fails to clear tip, see Reverse-A-Clean

instruction manual No. 307-321 CAUTION

NEVER hold your hand or a rag in front of spray

kWARNINGj

Always point the gun toward the ground or into a

To prevent stalling and possible stripping of gears,

don’t let water freeze in the pump in cold weather.

Before each use, squirt one drop of oil onto the lower

pivot point of the pump. See Fig 3.

Shutdown

and Care Of Your Unit

Check

packing nut/wet cup periodically and tighten only

as necessary. Overtightening may cause binding and

excessive packing wear.

Periodically, or if motor overheats, unplug unit, relieve

pressure according to Pressure Relief Procedure,

remove shield

and clean

all paint and dirt

off shield and

motor. Change gearbox lube

at

least once a year. Gear-

case holds 3 pt (1.4 liter). Don’t use hypoid grease.

Clean outlet filter

paint out of unit a

when storing

unit.

Flush all

on page 3, on that last

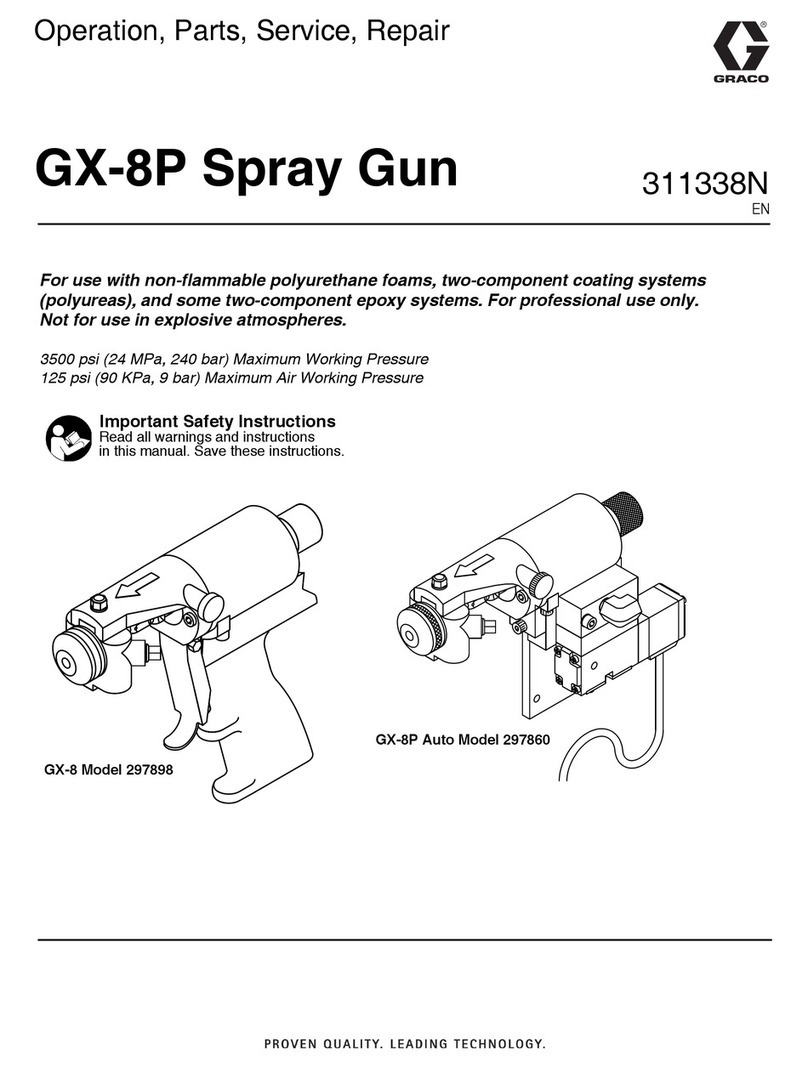

Once a month, lubricate needle bearing in displacement

rod; use a grease gun to apply grease to grease fitting.

See Fig 5.

4 307-075