Important

Note

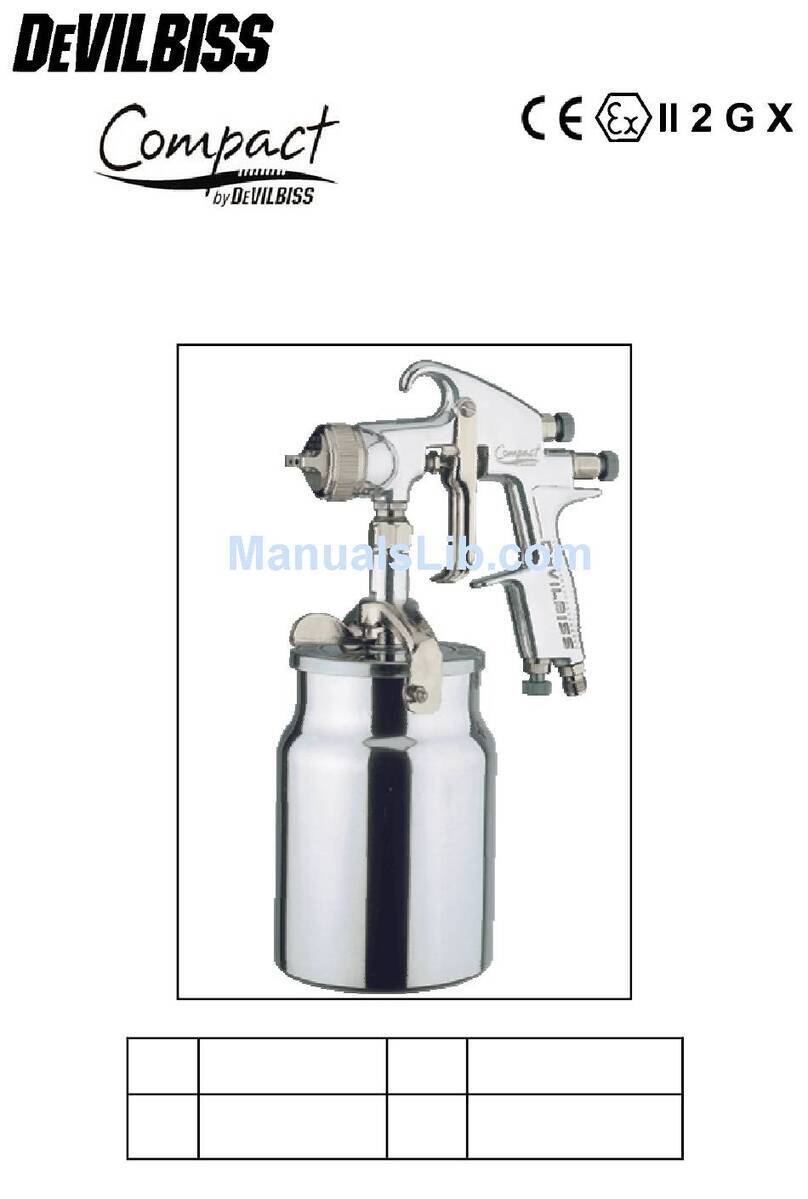

·The

SGA570

spny

~JUn

rs

a precisron tool, desrgned and

manufactured

to

render

high qualrty

trr.istl€<>

·In

order

to marntarn

rts

pertormance

characterrsrrcs it

rs

important

that

you

carefully

follow the mstructrons here:n

Application

WARNING'

CHLORINATED

SOLVENTES

SUCH

AS

111-TRJCHLOROETHANE

AND

METHYLENE

IN THIS

CHEMICALLY

REACT

WITH

THE

ALUMINUM

USED

IN

THIS

GUN.

THE

RESULT

OF

THIS

REACTION

CAN

RANGE

FROM

DESTRUCTIVE

CORROSION

TO

A

HAZARDOUS

EXPLOSION.

00

NOT

USE

THESE

SOLVENTS

WITH

THIS

SPRAY

GUN.

•The

SGA

spray

gun

was

developed

fo~

use

in

automobile

reparr

sr-.ops

and

general

maintenance

work

·It

rs

adequate

fm applyrng all

common

coating and frnishing materials,

excepting

ccmosrve.

abrasive

products anzi

those

With

very

high

viscosity.

How

it

Works

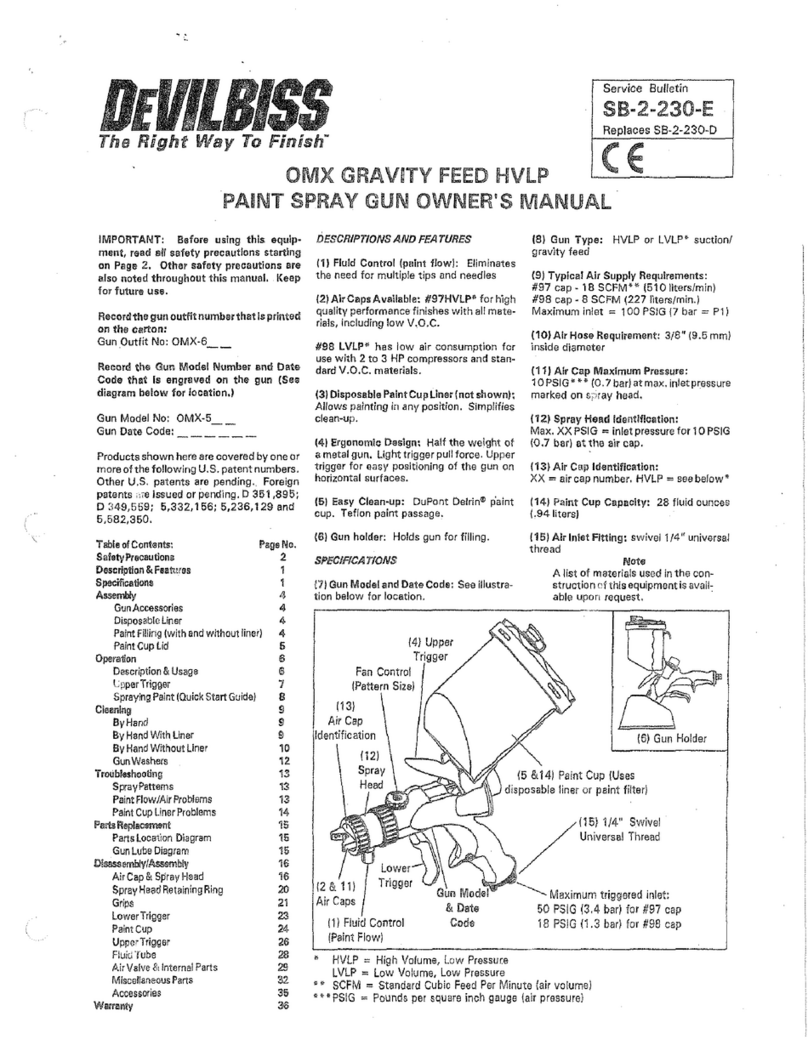

• The

SGA-570

DeVilbiSS

spray

gun

works

through suction it

draws

the

material

from the cup through a

suction

tube

• The pattern

1s

adjusted

by

the

top

knob

•

Flwd

flow

IS

adjusted

by

the

lower

one

Installation

For

better

performance

of

the

DeVilbiss

SGA-570

we

recommend

that

• The

DeVilbiss

air filter

regulator

be installed as close as

possible

to

the

spray

gun

•

The

mternal

diameter

of

the

DeVi/t)iss air

hose

should

not

be

less

than

5116", for a

maximum

length

of

50

feet (15 meters)

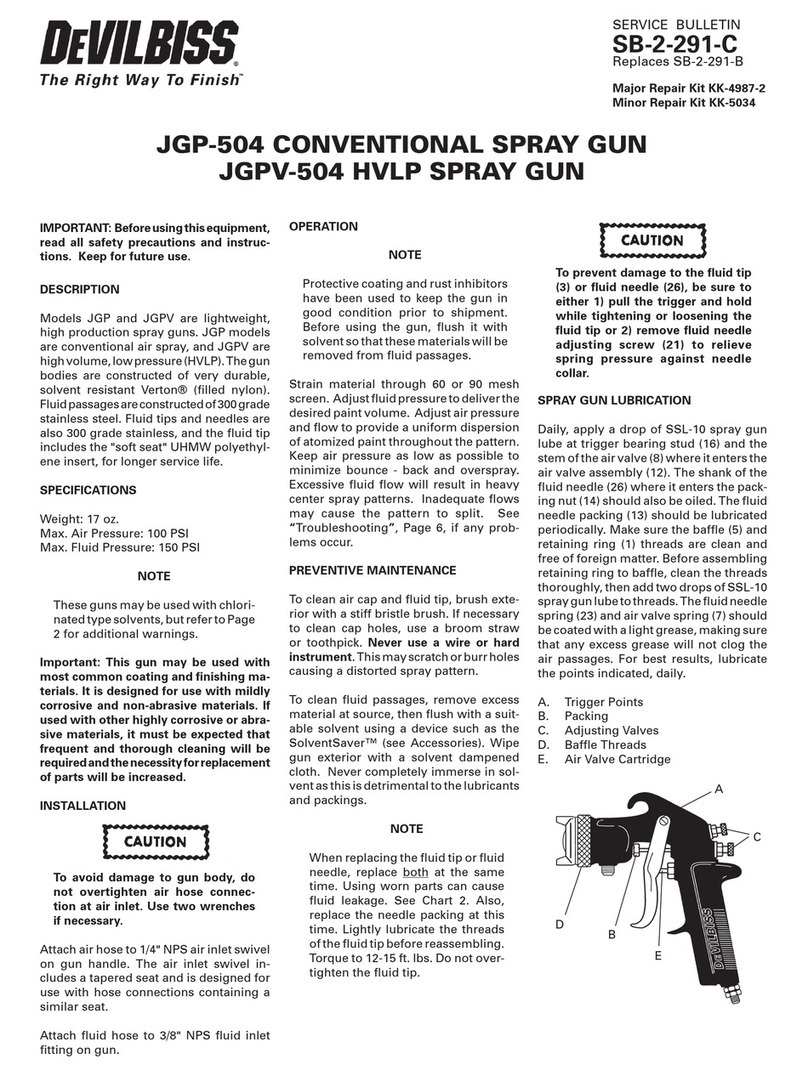

Operation

fhe

air

valve

assembly

(6)

is

under

pressure

whenever

the

gun

ts tnggered. If this

valve

is

turned

out

too far, it

may

!eave the

gun

forcefully

when

rhe

gun

is

triggered

Also,

the

"0"

ring (5)

may

be

dammaged

rf

the valve

is

turned

out

past

the

first

thread

[)o

not

turn the valve past

the

first thread

-there

will be no

effect

on

the

spray

pattern

after

that

positton.

•

Prepare

the

mate

nat

wt>ich is to be

sprayed

according

to

the

manufacturer's

n:structions and filter it

ttlrough

a

sueeen

of

at

least

60

mesh,

or

equivalent.

• Set

the

atr pressure

at

the

DeVilbiss

filter

regulator

to

about

35

p.s.i. to start.

•

Effect

a

spray

test

•

Spray

a test pattern.

Regulate

the fan by opemng

or

closing its

adjusting

knob

•

Spray

a

small

area

in

order

to

achieve

the

desired

job

speed

and

finish.

•

If

the ftnish

appears

to be

dry

or

rough, the

quanttty

of

material

is

small

in relation to

the air

pressure

Open the fluid regulating knob,

or

decrease

the air

presure

in

the

DeVilbiss

filter

regulator

until

you

achieve

a

wet

and full coattng.

•

Keep

the

spray

gun

always

perpendicular

to the surface

which

is to

be

painted

·Do

not

arc

the

gun

as thts

produces

an

uneven

coat

of

paint

·We

recommend

the spray

gun

be

kept

at

a

distance

of

6 to 8 inches from

the

''urface

• The positton

of

the air cap

determines

the

position

of

the

pattern

Twist

the

cap

;Jccording to

spraying

requenments

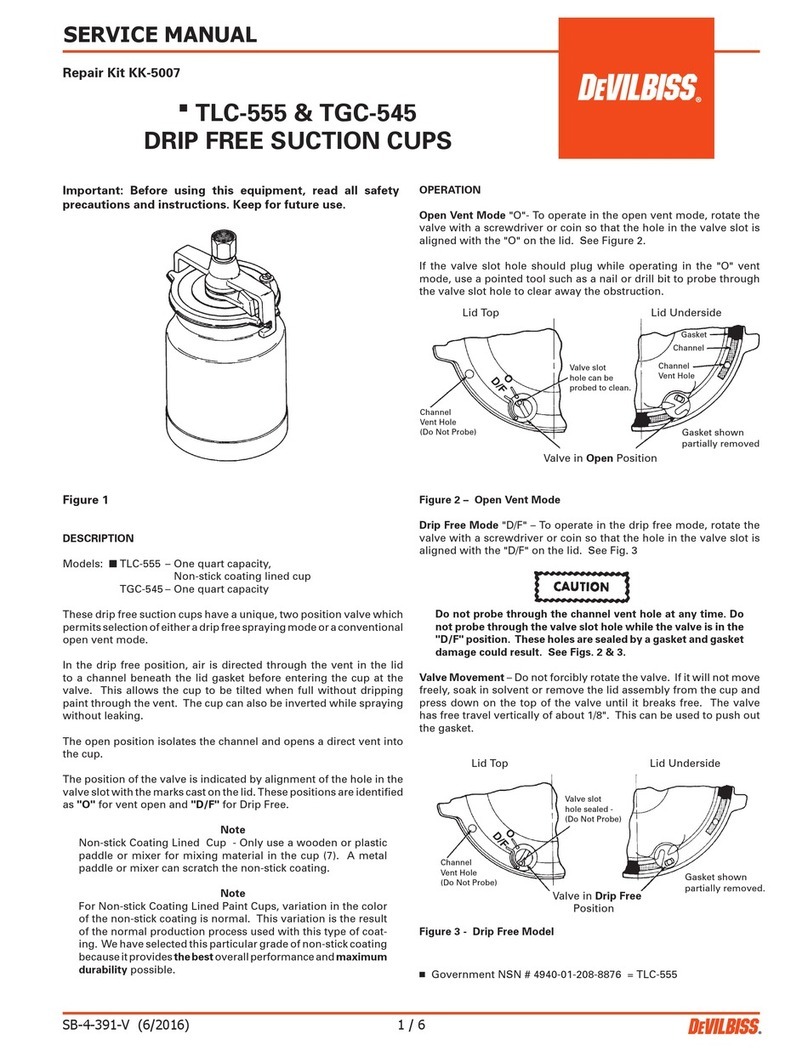

Cleaning

We

recommend

that the

spray

gun

be

cleaned daily,

or

after

each

time

the

equipment

is

used

Procedure

•

Remove

the

cup

Empty

the

remaining

matenal

from

the

cup

and

refill it with

about

c:ne

inch

of

suitable solvent.

•

Put

cup

back

on

gun

and

shake

same

• Pull

the

trigger

for

a while

•

loosen

the

cup

again and

clean

1!

Inside

w1th

a cloth

using

the

remaining

solvent.

Clean

also

the

lid and

suction

tube

•

Repeat

the flushing

procedure

at

least

once

aga1n.

•

W1pe

the

extenor

of

the

gun

with

a

solvent

dampened

cloth

•

If

necessary

,

remove

tne

air

cap

and

clean

1t

by

1mmers1ng

same

in

solvent

If

the

holes

have

clogged

use

a

toothpick

to

remove

the obstruction_

Never

use

wires

or

nails, as this could ruin the air

cap

•

Never

immerse

the

spray

gun

m

solvent

since

this

destroys

the

lubricants

and

packmgs

Lubrication

·Lubricate

.daily

w1th

thin oil

the

tngger

bear1ng stud (17), the fluid

needle

(10),

close

to the

packtng

(14),

the

threads

of

the

valve

assembly

(6) and

the

exposed

part

of

the

wr

valve

(8)

•

Periodically

cover

the

springs

of

the

needle

(1

1)

and

of

the

air

valve

(9) with

vaseline

or

thm grease

When

to

change

the

tip

and needle

The tip

and

netedle should he replau::d

when

·There

occurs

wea1

of

the

11p,

ol

the

needle

or

th'~

sent

d the t!p

• There are

SIQrls

of

wear

on

the needle

at

the pornt

of

contact

W!th

1t1e

packmg

•

NE'·ver

replace on!y

th('

fluid tip (3)

or

the need!e (10)

Al>w1ys

chanQe both

of

t~em

·The

t1p

should

be

screwed

on

carefully

1n

order

not to

hurt

tile

(hre:vJ

of

the

gun

body.

Thtghten

1!

tor a good sealing. but

never

over-ltghten

it Always

use

ttle

DeV1Ibiss

BSGA-29

wrench

Always

ttghten the fluid ttp before assernlJhng the

neediH rnto the

gun

body

• The t:p

should

be

screwed

on

carefully

1rl

order

not

to

hurt

the

thread

of

th•:

gun

body

Tighten

1\

lor a

good

sealmg. but

new:r

ove~-trghlH\

rt

Always

t/>e tr;e

DeVilbiss

BSGA-29

wrench_

Always

t1ghtr::m

the

Hu:d

tip with a

torque

of

15

to

17

Ft Lbs.

before

assembling

the

needle into

the

gun

body

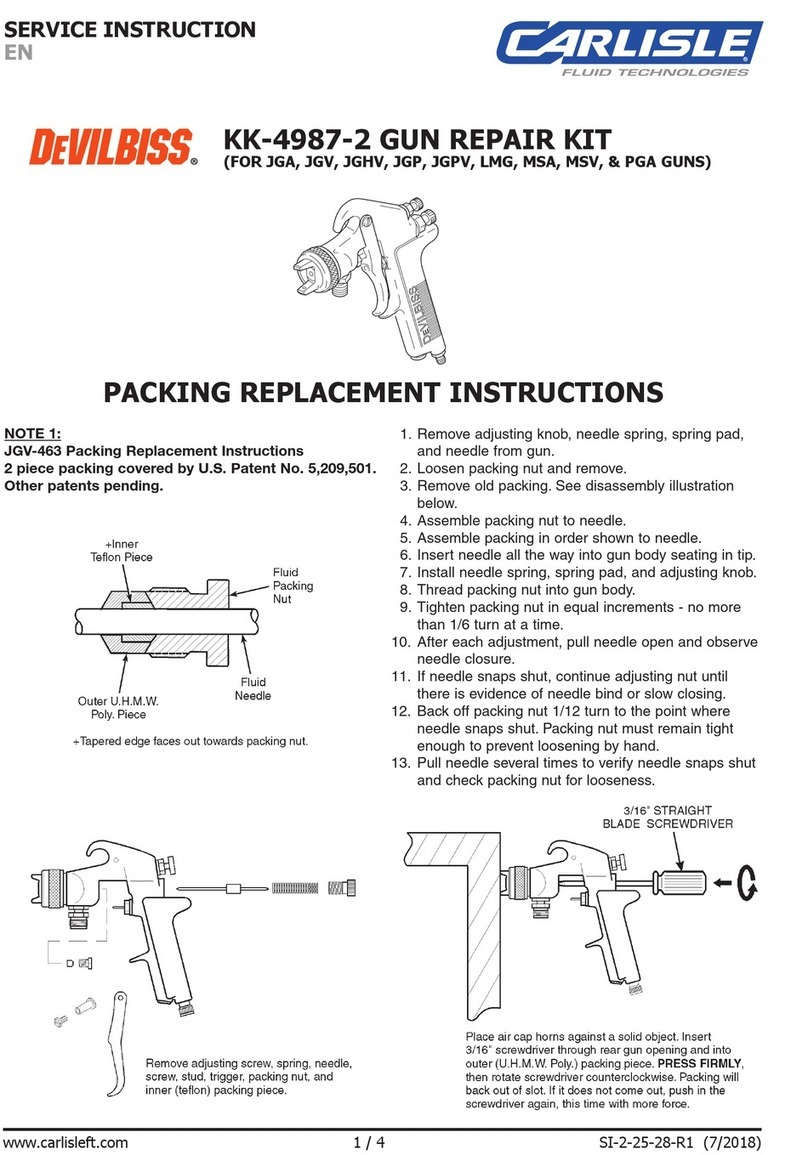

• Always

replace

the packrng (14)

whHl

you assernbie a

new

set of

t1p

and

needle

Lubrtcate the

new

p8.cking oefore asse-mbly

·The

packing

nut

(15)

should

be

just

t1ght

enough

and

not

hmder

the free

movement

of the

needle

REPAIR KITS

K-5001

K-5004

~-

··r

QTY

: DeV.

DESCRIP_!"!_?.N.

QTY.

DeV. DESCRIPTION

'

~-~~-~

j

BSGA-32

F!Uid

tip

j

BSGB-15

Packtng

j I

BSGA-404

Fluid

needle

3

BSS-601011

"0"

Ring

2

'BSGS-15

Packmg

BSS-601109

"O"

R1ng

BSGB·5

Baffle 1

BSGA-49

Sprmg

I j

CGA-40

Spring

i j

BSGA-16

Tngger

pin

2

SST-8416

Snap

nng

HOW TO REQUEST REPLACEMENT PARTS

When

requestmg

replacement

parts always

g1ve

the ·1. Kit

or

Part

Code-2

Description

of

same

-3 Type

ol

spray

gun

SERVICE CHECKS

'

'

) (

•

:

Condition

Top/or

bottom

heavy

pattern

Heavy

right

or

left

s1de

pattern

Heavy

center

pattern

Spilt

spray

pattern.

Jerky

or

fluttering

spray

Cause

1

Matenal

build

up

on

atr cap

2 Partially

plugged

horn

holes,

center

hole or

jets

'3.

Matenal

partially

i

plugged

flwd

tip

!4

Dammaged

fluid tip.

1.

Too

much

material

2 Material

too

thick

I'

Pressure

is

too

high

2.

Not

enough

material

1 InsuffiCient flwd

in

cup.

2

Gun

and

cup

tipped

at

excessive

angle

3 OtstniCted

fluid

passage

4

loose

or

cracked

fluid tube in

cup

i 5.

loose

fluid

tip

or

I cracked fluid tip

seat

6. Too

heavy

fluid for

suction feed

i

7.

Dry

or

worn

packing

I (14)

or

loose

packing

nut

(15)

________

i

Will

not

spray

1

1

Low

air

pressure

1

at

gun

l2

Closed

fluid

adjusting

! knob

1

3

Too

.heavy fluid

tor

suctton feed

, 4

loose

a1r

cap

I

Correction

--r-

'1.

Remove

cap and

soak

it

in

suitable sotvent

and

wipe

clean (See Cleaning)

2

Same

as

above

3.

Remove

ffuid

tip

and

clean same with soivent.

4.

Replace

t1p

and

needle

set

(See

When

toChan_;je

~~.Pard

Need~)

1

Reduce

flUid

flow

by

turning needle adjusting

knob clockwise or increase

air

pressure

in

th'2

DeVilbls.s

filter regulator.

2

Thin

matenal

1.

Reduce

a11

pressure

of

the DeVilb1ss filter

regulator.

2.

Ir.crease fluid flow

by

turning fluid

needle

adjusting

knob

counterclockwise

1

F1ll

cup

2

Do

not

tip

excessively

or rotate fluid

tubE:>

in

cup.

3.

Clean

same

4

Tighten

or

rep!ace

same

5 T1ghten

or

replace

the

lip

and needle

set

6 Thtn

matenal

7.

lubncate

or

replace

packing

or tighten

packing

nut

Ched< air lines or 1mease

pressure

at

OeVrlbiss

air

filter regulator.

2.

Open

same

..

(See

Operal!On)

j 3

Thin

material

4 Tighten

same

Dripping

from

_____

ft~,uid

tip.

--[1.-

Worn

or

damaged

-;rp

_i~~.

need

I~-

---·-

....

-

..

Replace

ttp

and

needle

set

(See

When

to

C~an_g_e

Tip

an_d_

Needle)-~

~

DEVILBISS

~

RAMSBURG

DeVilbiss

Ransburg

Industrial

Coating

Equipment

17241ndian

Wood

Circle

INDUSTRIAL

COATING

EQUIPMENT

Mawmee,

OH

43537

SB2A95C

06/91