5307001

Installation

General

Note: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and parts

drawings.

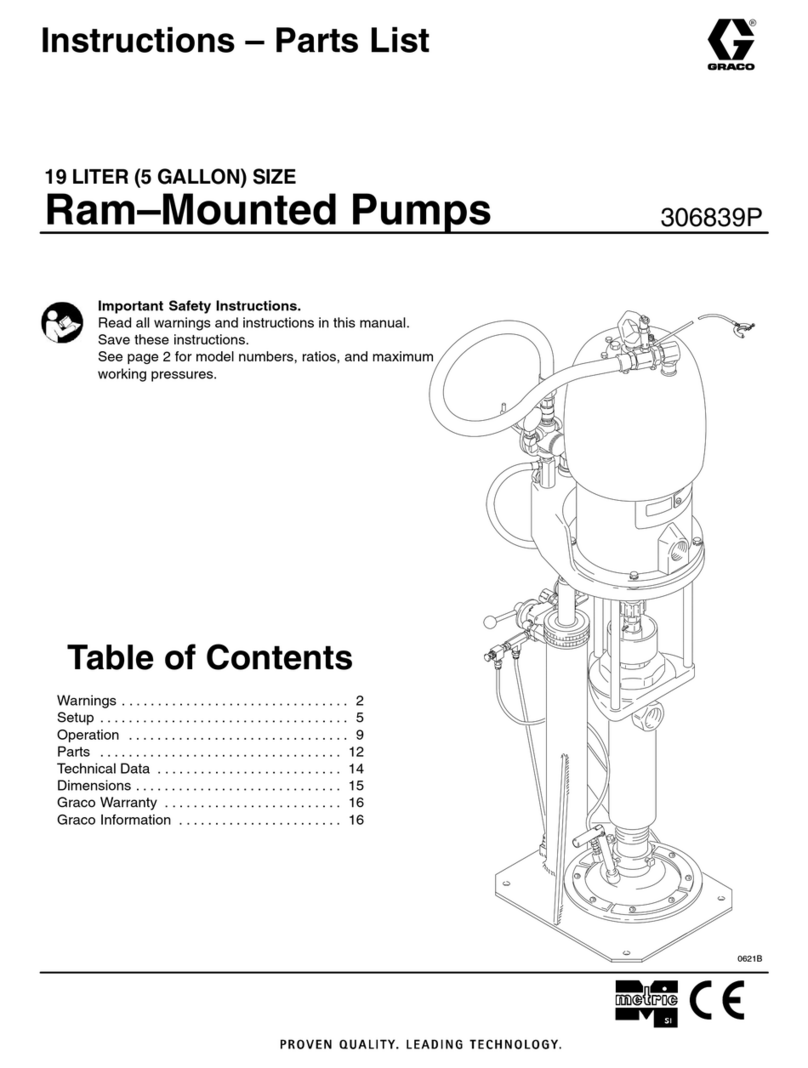

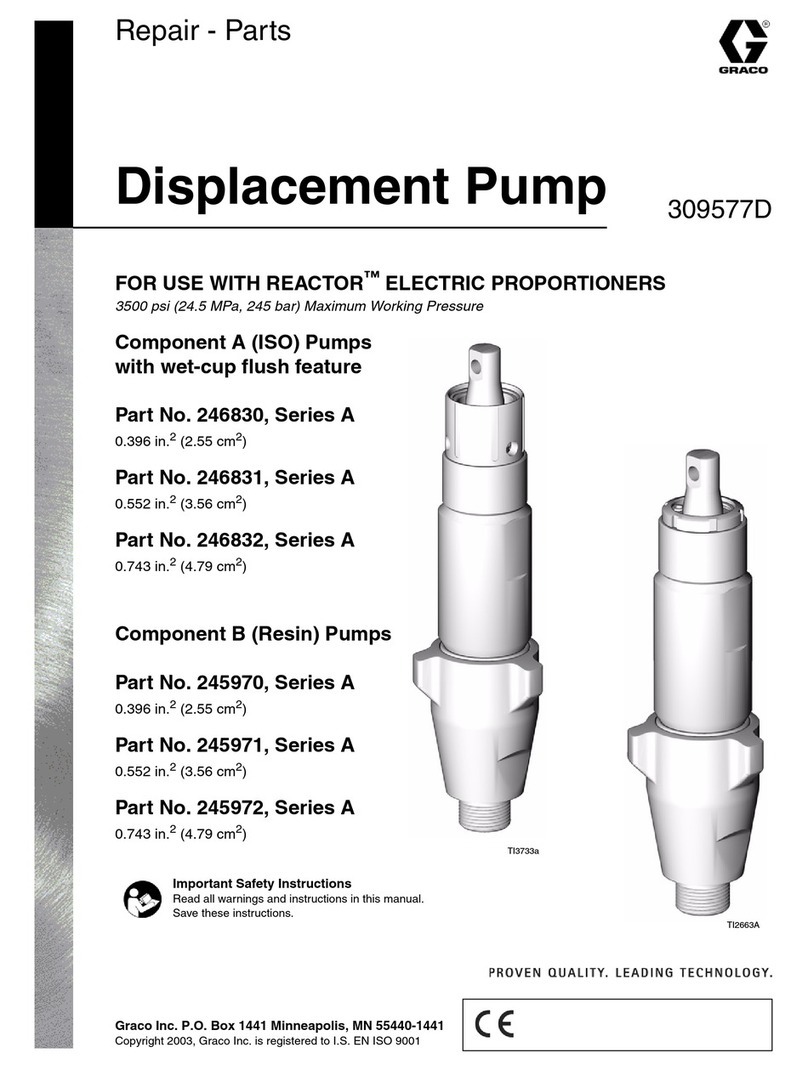

DThese pumps are designed to be part of a Hydra-

CatRsprayer that will proportion, mix, and spray

polyurethane chemicals. Refer to your separate

Hydra-CatRinstructions. If you are using this

pump to mix antifreeze and water, refer to page 9

for special plumbing instructions.

DMount the pump to suit the type of installation

planned. The pump dimensions and mounting hole

layout are shown on page 11.

DThe pump is supplied with a 3/4 npt(m) intake

nipple. If your installation requires a 3/4 npt(f) or 1”

npt(m) intake, remove and discard the 3/4 npt(m)

nipple, and connect your plumbing directly to the

intake housing. Refer to manual 307430 for a parts

breakdown of the displacement pump.

WARNING

Two accessories are required in your system: a

bleed-type master air valve and a fluid drain valve.

These accessories help reduce the risk of serious

injury, including splashing in the eyes or on the

skin, and injury from moving parts if you are adjust-

ing or repairing the pump.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the air is

shut off. Trapped air can cause the pump to cycle

unexpectedly. Locate the valve close to the pump.

The fluid drain valve assists in relieving fluid pres-

sure in the displacement pump, hose, and gun;

triggering the gun to relieve pressure may not be

sufficient.

Grounding

To reduce the risk of static sparking, ground the spray-

er and all other spray equipment used or located in the

spray area. Check your local electrical code for de-

tailed grounding instructions for your area and type of

equipment. Ground all of this spray equipment:

DPump: use a ground wire and clamp to connect the

sprayer to a true earth ground. See Fig. 1.

DFeed pumps: use a ground wire and clamp to

connect the pump to a true earth ground. See your

separate feed pump instruction manual.

DAir compressors: refer to manufacturer’s recom-

mendations.

DAir and Fluid Hoses: use only grounded hoses and

check resistance regularly.

DHeaters: wire into a properly grounded power

supply. If using a generator, be sure it is positively

connected to a true earth ground.

DSpray gun: obtain grounding through connection to

a properly grounded fluid hose and sprayer.

DFluid supply containers: according to local code.

DObject being sprayed: according to local code.

DAll solvent pails used when flushing, according to

local code. Use only metal pails, which are conduc-

tive, placed on a grounded surface. Do not place

the pail on a non-conductive surface, such as paper

or cardboard, which interrupts grounding continuity.

DTo maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

gun firmly to the side of a grounded metal pail, then

trigger the gun.

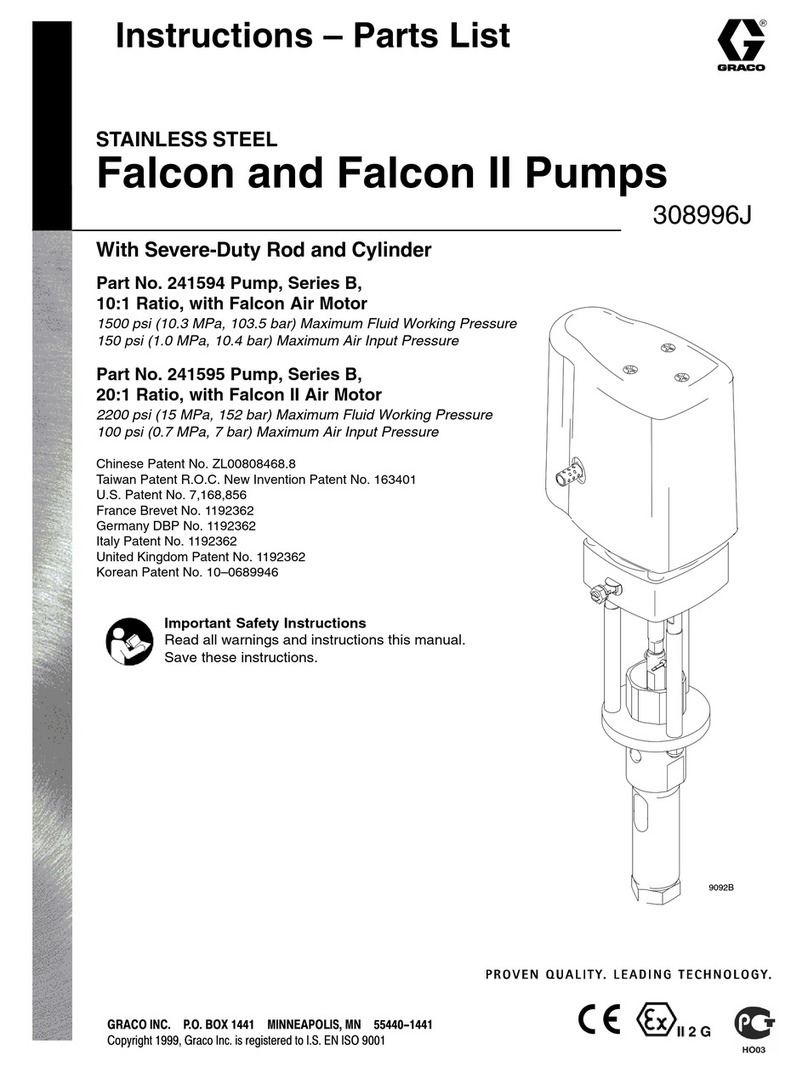

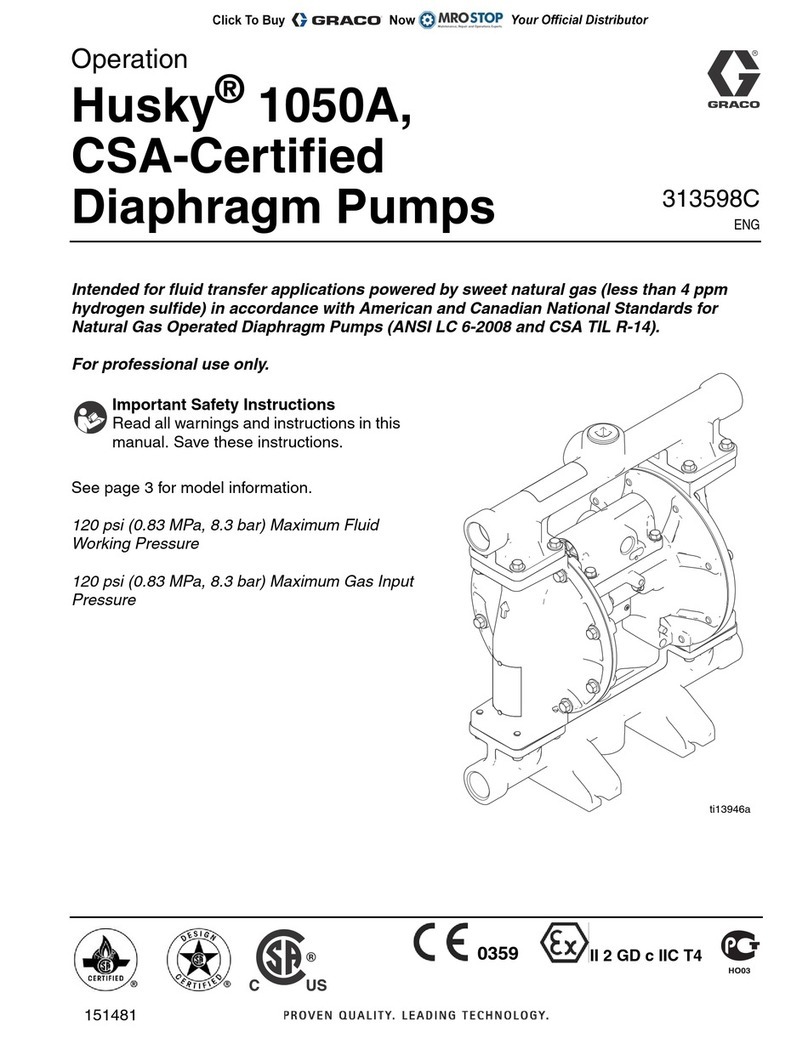

To ground the pump, loosen the grounding lug locknut

(W) and washer (X). Insert one end of a 12 ga (1.5

mm2) minimum ground wire (Y) into the slot in the lug

(Z) and tighten the locknut securely. See Fig. 1. Con-

nect the other end of the wire to a true earth ground.

Order Part No. 222011, grounding wire and clamp.

Fig. 1 0720

Y

W

X

Z