6307–917

Setup

Supplied Components

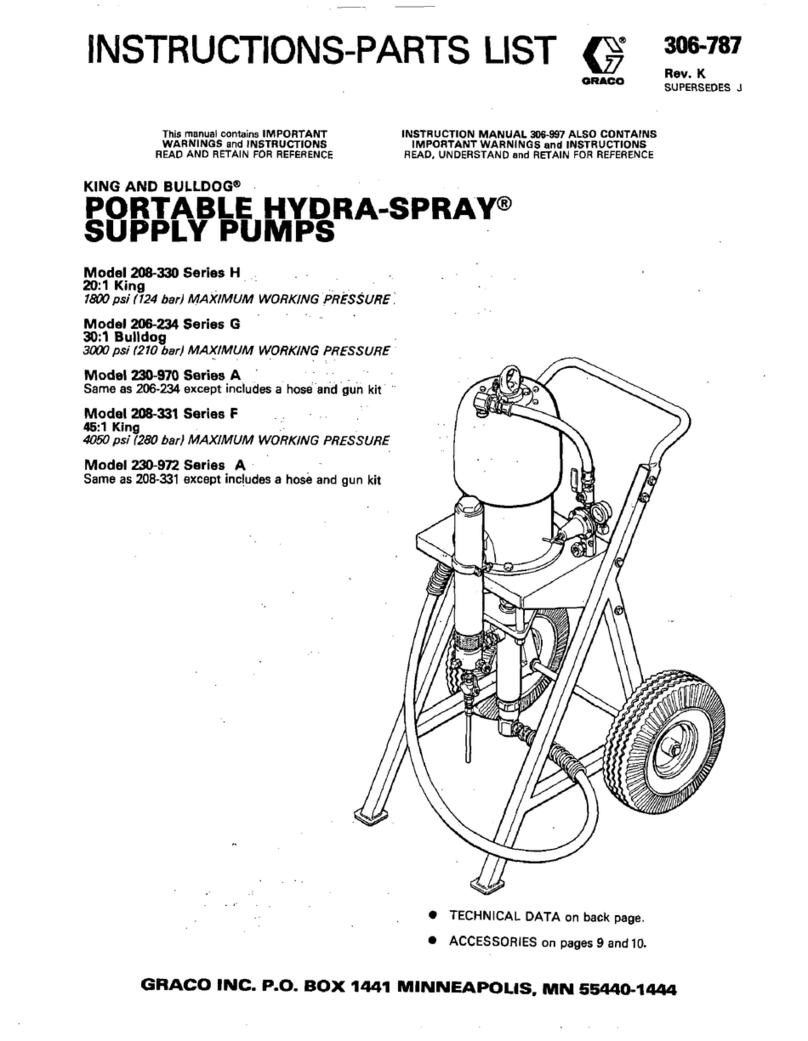

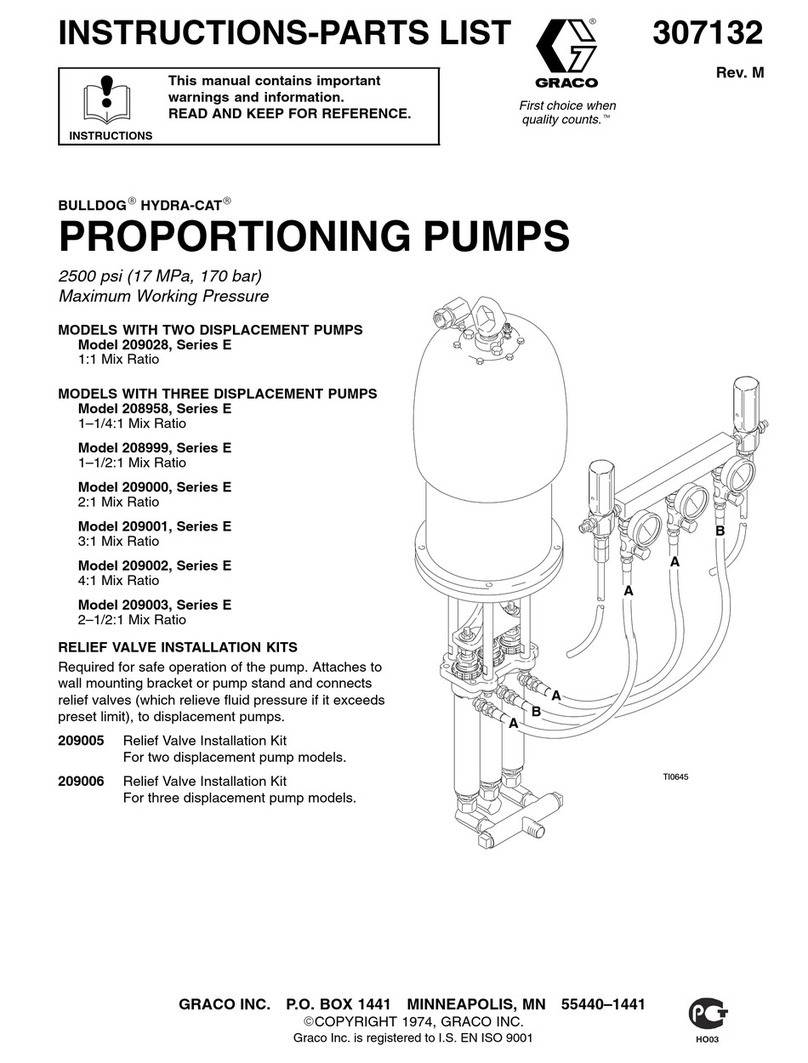

Refer to Figs. 2 and 3.

WARNING

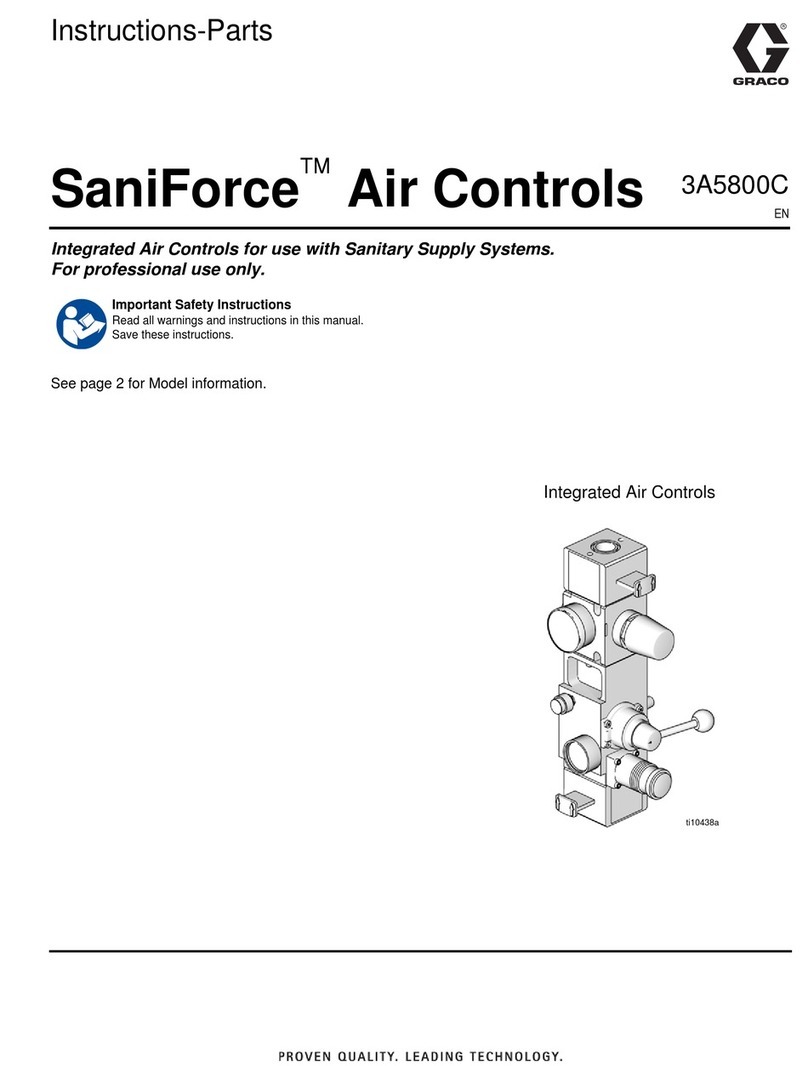

A red-handled bleed-type master air valve (F) and

a fluid drain valve (G) are required, to help reduce

the risk of serious injury, including fluid injection

and splashing of fluid in the eyes or on the skin,

and injury from moving parts if you are adjusting or

repairing the pump.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the air is

shut off. Trapped air can cause the pump to cycle

unexpectedly. Locate the valve close to the pump.

The fluid drain valve assists in relieving fluid pres-

sure in the displacement pump, hose, and gun.

Triggering the gun to relieve pressure may not be

sufficient.

DThe red-handled bleed-type master air valve (F)

is required in your system to relieve air trapped

between it and the air motor when the valve is

closed (see the WARNING above). Be sure the

bleed valve is easily accessible from the pump, and

is located downstream from the pump air regulator

(B).

DThe pump air regulator (B) controls pump speed

and outlet pressure by adjusting the air pressure to

the pump. Locate close to the pump, but upstream

from the bleed-type master air valve (F).

DThe pre-set safety valve (506) prevents overpres-

surization of the spray gun by opening automatical-

ly if the incoming air pressure to the pump exceeds

6.6 bar, 0.66 MPa (95 psi).

DThe gun air regulator (C) controls the air pressure

to the spray gun (H).

DThe air line fitting (502) and coupler (503),

connect the main air line to the air/fluid regulator.

Disconnect the coupler from the pin fitting and

screw it onto the end of your air supply hose. Do

not reconnect the coupler to the pin fitting at this

time.

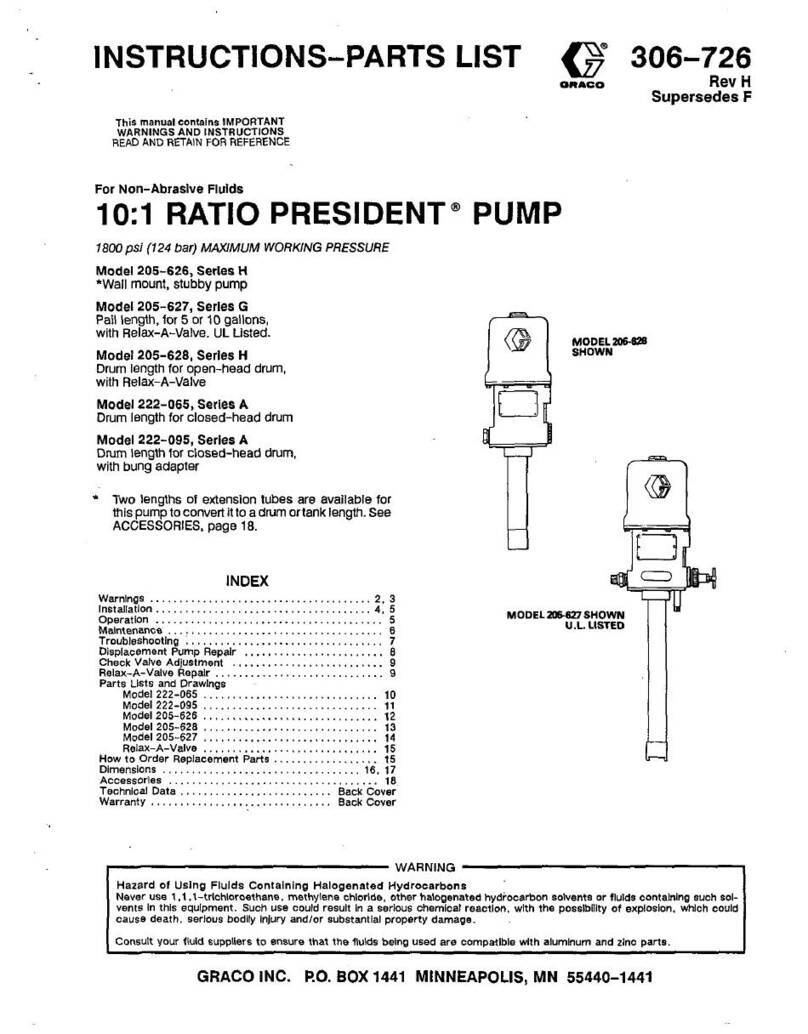

Wall Mount System Setup (See Fig. 3)

Install the bung adapter plate (306) on the wall

bracket, using the two hex screws (303) and nuts

(304).

Mount the wall bracket (305) 1.5 m (5 ft) above the

floor. Refer to wall bracket manual 306-783 for instruc-

tions. Be sure the wall is strong enough to support the

weight of the equipment, fluid, and hoses, and with-

stand the stress caused during pump operation.

Remove the bung adapter (18) from the pump and

screw it tightly into the bung adapter plate (306). Lower

the pump (A) through the bung adapter. Tighten the

screw on the bung adapter to hold the pump steady.

Apply thread sealant and screw the suction tube

assembly (307) into the pump’s fluid intake valve.

Setup Procedure for all Models (Refer to

Figs. 2 or 3, as applicable)

System Accessories

Install an air line filter (D) in the main air line (E), to

remove harmful dirt and moisture from the compressor

air supplied to the pump and gun.

Near the pump’s fluid outlet, install a tee and drain

valve (G).

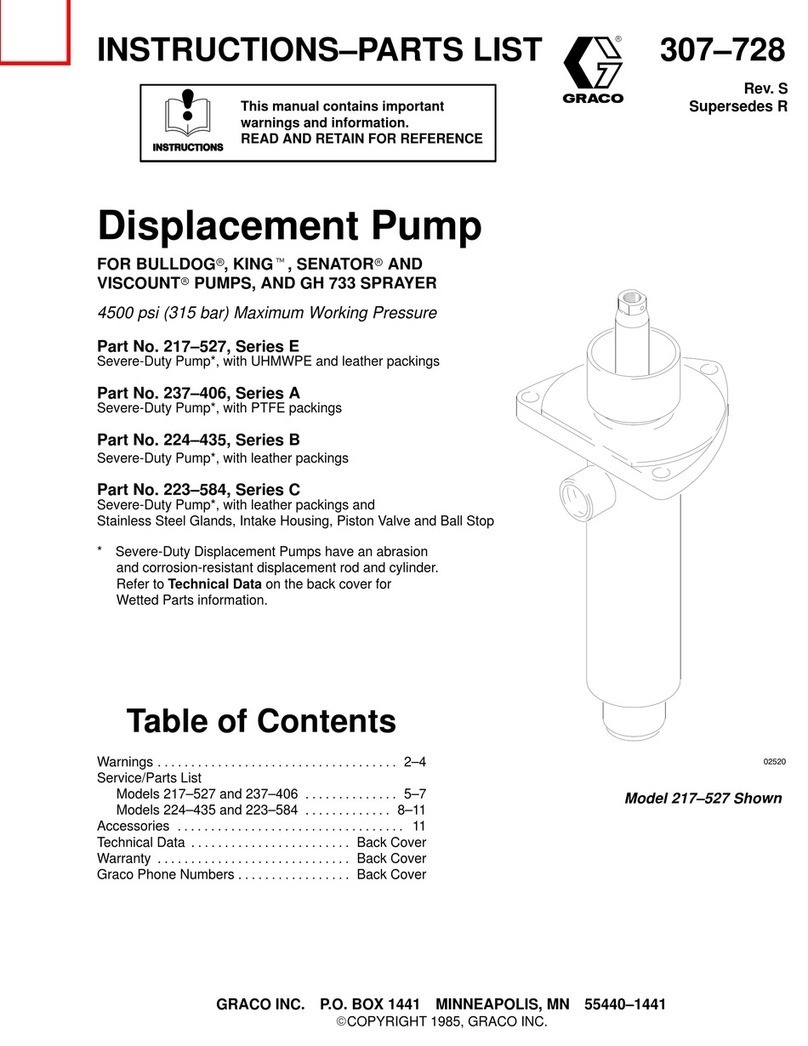

Hose and Gun Connections

The Hose Kit consists of the spray gun’s air and fluid

supply hoses. The fluid hose (401) has spring guards

on both ends, and includes an in-line fluid filter (402) at

the gun end. The hoses are tied together for ease of

movement.

Connect the male end of the air hose (403) to the 1/4

npsm(f) swivel adapter (509) at the outlet of the gun air

regulator (C), and connect the female end to the air

inlet in the spray gun (H) handle.

Connect the male end of the fluid hose (401) to the

pump’s fluid outlet, and connect the female end to the

gun’s fluid inlet. Do not install the spray tip in the gun

at this time.