DECALS

2.0

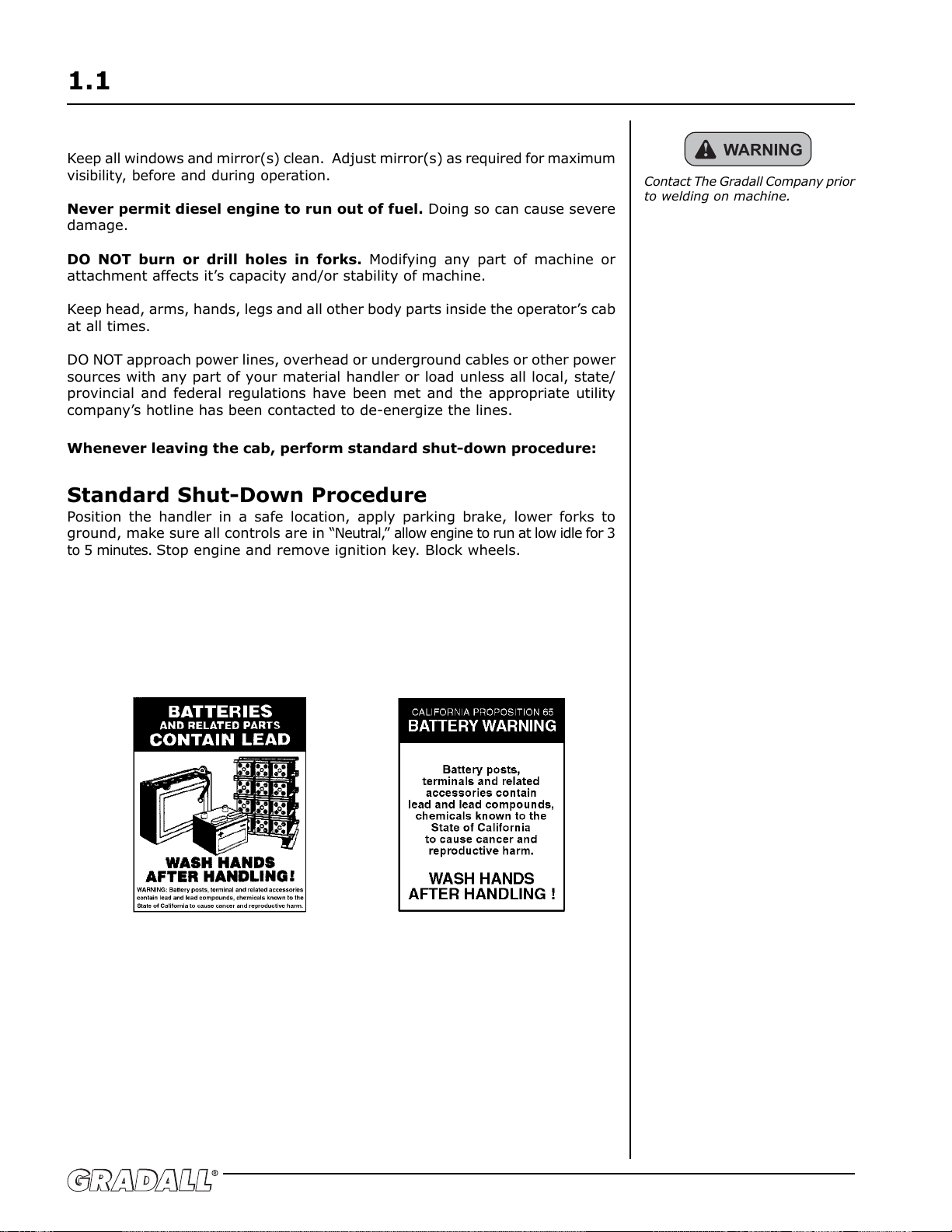

INSIDE THE CAB

TRACTION LOCK

9140-3529

LOCKS FRONT & REAR AXLES

HYDRAULICALLY FOR INCREASED

TRACTION DO NOT USE ON

IMPROVED SURFACES

MACHINE MUST BE IN WORK

MODE

9132-3030

NEVER OPERATE MACHINE WITHOUT

CONSULTING PROPER CAPACITY CHART FOR THE

CARRIAGE/FORK COMBINATION BEING USED

R

9140-3618

FRONT

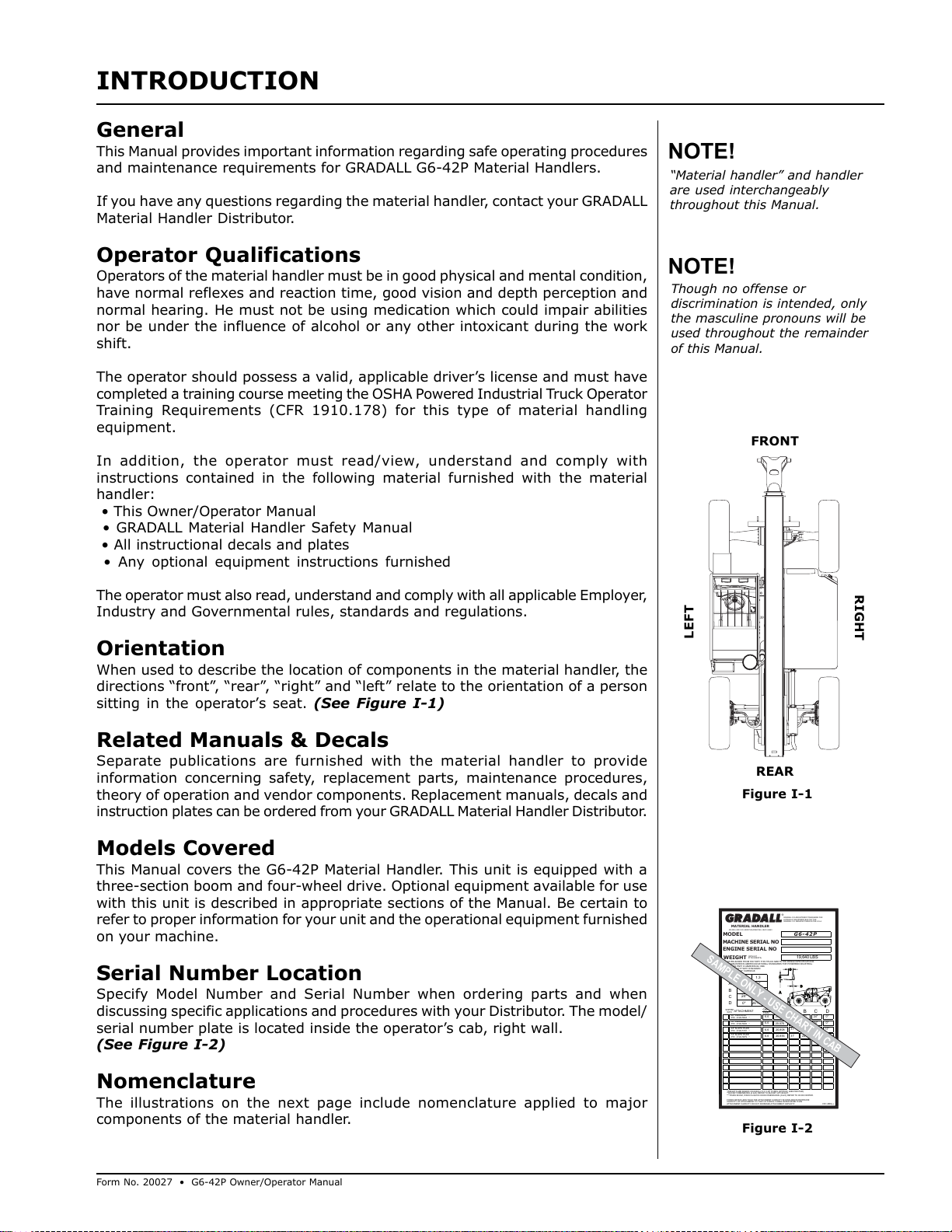

GENERAL

NOTES

9140-3618

LEVEL GRADALL HANDLER BEFORE LIFTING ABOVE 4 FT

USE CAPACITY CHART FOR SPECIFIC ATTACHMENT ON MACHINE

FOR OTHER ATTACHMENTS CONSULT A GRADALL DEALER

FOR LOAD RATINGS NOT LISTED

USE LARGEST NUMBER VISIBLE FROM THE CAB TO

DETERMINE BOOM EXTENSION

MATCH WITH BOOM ANGLE TO DETERMINE ALLOWABLE LOAD

FIGURES SHOWN ARE STACKING CAPACITY TRUCK LEVEL

RATED LIFTING CAPACITIES SHOWN ARE WITH MACHINE ON A FIRM,

LEVEL SURFACE WITH UNDAMAGED, PROPERLY INFLATED TIRES

MACHINE SPECIFICATIONS AND STABILITY ARE BASED ON RATED LIFT

CAPACITIES AT SPECIFIC BOOM ANGLES AND BOOM LENGTHS

IF SPECIFICATIONS ARE CRITICAL, THE PROPOSED APPLICATION

SHOULD BE DISCUSSED WITH YOUR DEALER

DO NOT EXCEED RATED LIFT CAPACITY LOADS, AS UNSTABLE AND

DANGEROUS MACHINE CONDITIONS WILL RESULT

DO NOT TIP THE MACHINE FORWARD TO DETERMINE ALLOWABLE LOAD

CERTAIN CARRIAGE/FORK COMBINATIONS MAY CAUSE HANDLER TO TIP

WITHOUT LOAD WHEN EXTENDED INTO "NO OPERATION" ZONE AS NOTED

ON CAPACITY CHART

CAPACITY LIMITS FOR THIS UNIT ARE BASED IN

ACCORDANCE WITH STANDARDS LISTED ON SERIAL

NUMBER PLATE

BACK

SAMPLE ONLY - USE CHART IN CAB

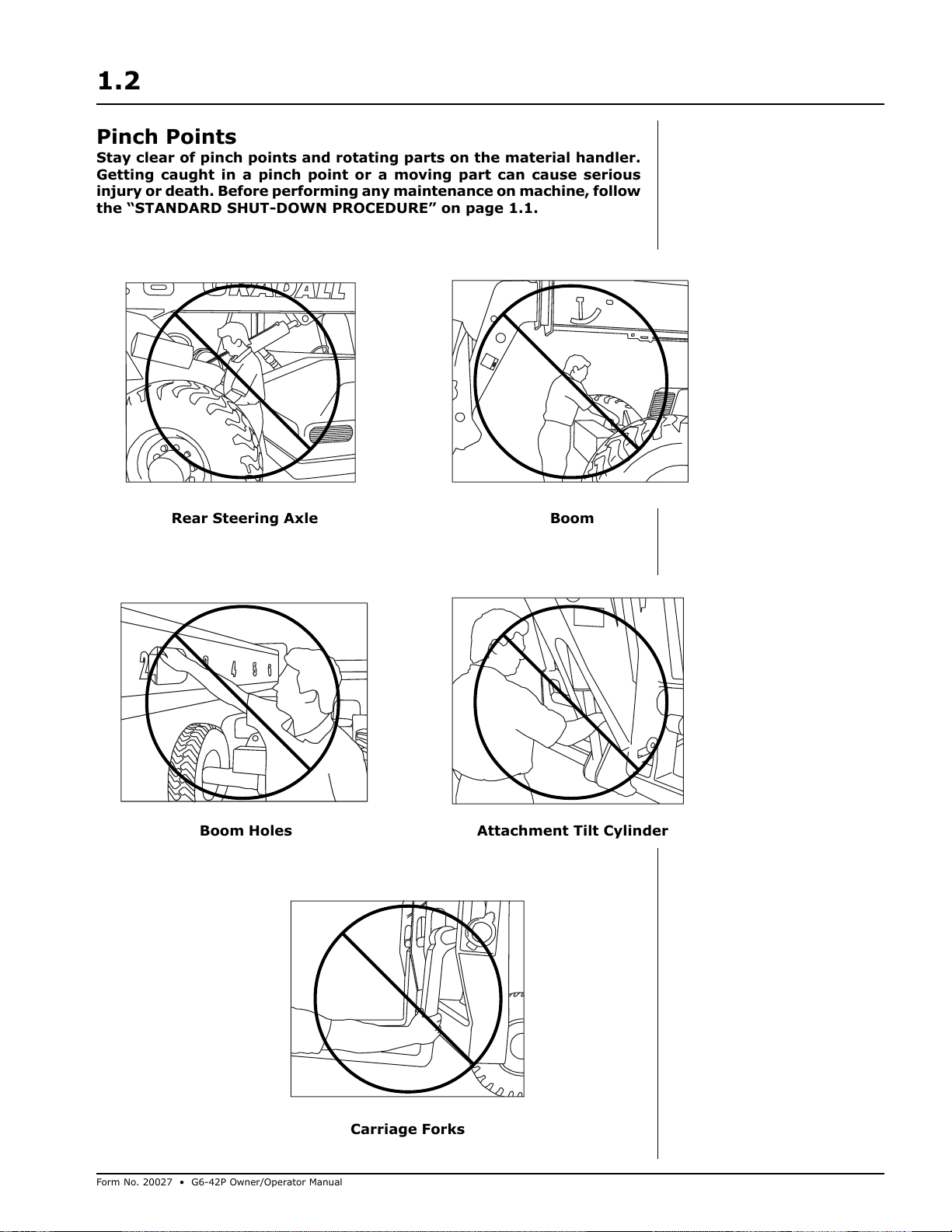

Located on dashboard

P/N 9140-3618

Located on dashboard

P/N 9141-3011

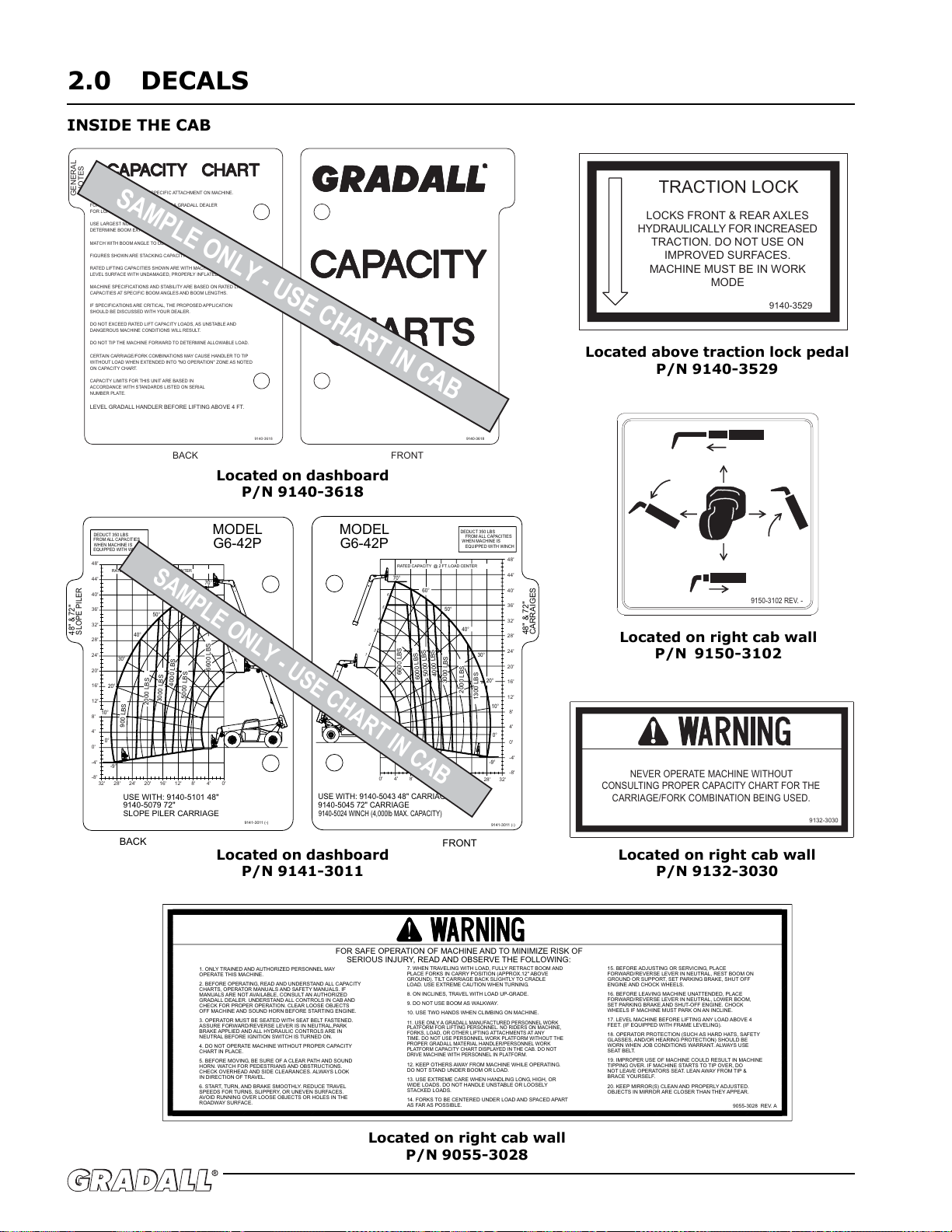

Located on right cab wall

P/N 9055-3028

Located on right cab wall

P/N 9150-3102

Located above traction lock pedal

P/N 9140-3529

Located on right cab wall

P/N 9132-3030

6000 LBS

USE WITH: 9140-5043 48" CARRIAGE

9140-5045 72" CARRIAGE

9140-5024 WINCH (4,000lb MAX CAPACITY)

9141-3011 (-)

FRONT

48" & 72"

CARRAIGES

MODEL

G6-42P

DEDUCT 350 LBS

FROM ALL CAPACITIES

WHEN MACHINE IS

EQUIPPED WITH WINCH

5000 LBS

4000 LBS

2000 LBS

3000 LBS

1300 LBS

RATED CAPACITY @ 2 FT LOAD CENTER

1

2

3

4

5

6

0'

-4'

-8'

4'

8'

12'

16'

20'

24'

28'

32'

36'

40'

44'

0' 4' 8' 12' 16' 20' 24' 28' 32'

48'

-9°

0°

10°

20°

30°

40°

50°

60°

70°

6600 LBS

48" & 72"

SLOPE PILER

9141-3011 (-)

BACK

DEDUCT 350 LBS

FROM ALL CAPACITIES

WHEN MACHINE IS

EQUIPPED WITH WINCH

MODEL

G6-42P

USE WITH: 9140-5101 48"

9140-5079 72"

SLOPE PILER CARRIAGE

1

2

3

4

5

6

5000 LBS

4000 LBS

2000 LBS

3000 LBS

900 LBS

RATED CAPACITY @ 2 FT LOAD CENTER

0'

0'

4'

8'

12'

16'

20'

24'

28'

32'

36'

40'

44'

-4'

-8'

4'8'

12'16'20'24'28'32'

48'

60°

70°

50°

40°

30°

20°

10°

0°

-9°

6600 LBS

SAMPLE ONLY - USE CHART IN CAB

8 ON INCLINES, TRAVEL WITH LOAD UP-GRADE

9 DO NOT USE BOOM AS WALKWAY

10 USE TWO HANDS WHEN CLIMBING ON MACHINE

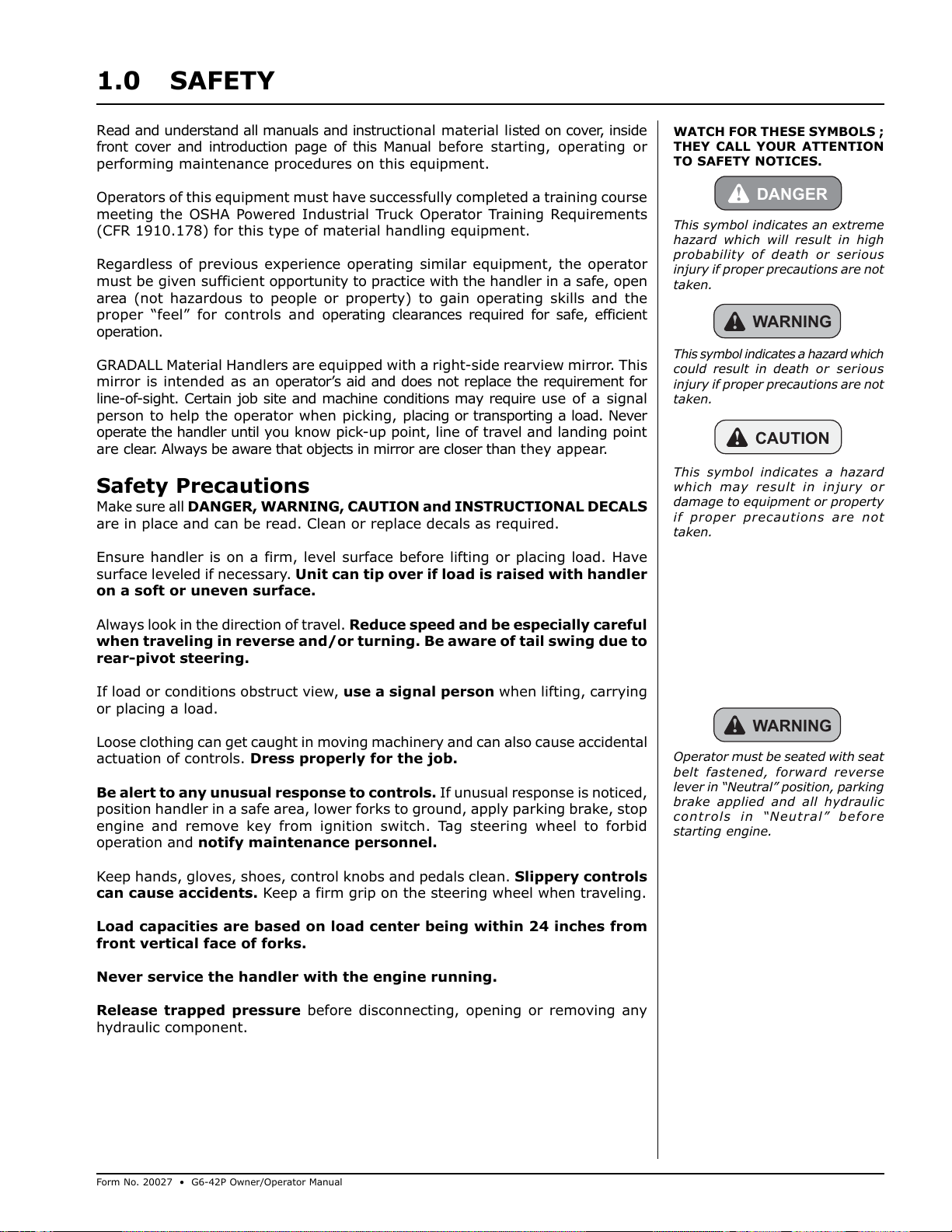

1 ONLY TRAINED AND AUTHORIZED PERSONNEL MAY

OPERATE THIS MACHINE

2 BEFORE OPERATING, READ AND UNDERSTAND ALL CAPACITY

CHARTS, OPERATOR MANUALS AND SAFETY MANUALS IF

MANUALS ARE NOT AVAILABLE, CONSULT AN AUTHORIZED

GRADALL DEALER UNDERSTAND ALL CONTROLS IN CAB AND

CHECK FOR PROPER OPERATION CLEAR LOOSE OBJECTS

OFF MACHINE AND SOUND HORN BEFORE STARTING ENGINE

3 OPERATOR MUST BE SEATED WITH SEAT BELT FASTENED

ASSURE FORWARD/REVERSE LEVER IS IN NEUTRAL,PARK

BRAKE APPLIED AND ALL HYDRAULIC CONTROLS ARE IN

NEUTRAL BEFORE IGNITION SWITCH IS TURNED ON

4 DO NOT OPERATE MACHINE WITHOUT PROPER CAPACITY

CHART IN PLACE

5 BEFORE MOVING, BE SURE OF A CLEAR PATH AND SOUND

HORN WATCH FOR PEDESTRIANS AND OBSTRUCTIONS

CHECK OVERHEAD AND SIDE CLEARANCES ALWAYS LOOK

IN DIRECTION OF TRAVEL

6 START, TURN, AND BRAKE SMOOTHLY REDUCE TRAVEL

SPEEDS FOR TURNS, SLIPPERY, OR UNEVEN SURFACES

AVOID RUNNING OVER LOOSE OBJECTS OR HOLES IN THE

ROADWAY SURFACE

7 WHEN TRAVELING WITH LOAD, FULLY RETRACT BOOM AND

PLACE FORKS IN CARRY POSITION (APPROX 12" ABOVE

GROUND) TILT CARRIAGE BACK SLIGHTLY TO CRADLE

LOAD USE EXTREME CAUTION WHEN TURNING

11 USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK

PLATFORM FOR LIFTING PERSONNEL NO RIDERS ON MACHINE,

FORKS, LOAD, OR OTHER LIFTING ATTACHMENTS AT ANY

TIME DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN THE CAB DO NOT

DRIVE MACHINE WITH PERSONNEL IN PLATFORM

12 KEEP OTHERS AWAY FROM MACHINE WHILE OPERATING

DO NOT STAND UNDER BOOM OR LOAD

13 USE EXTREME CARE WHEN HANDLING LONG, HIGH, OR

WIDE LOADS DO NOT HANDLE UNSTABLE OR LOOSELY

STACKED LOADS

14 FORKS TO BE CENTERED UNDER LOAD AND SPACED APART

AS FAR AS POSSIBLE

15 BEFORE ADJUSTING OR SERVICING, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, REST BOOM ON

GROUND OR SUPPORT, SET PARKING BRAKE, SHUT OFF

ENGINE AND CHOCK WHEELS

16 BEFORE LEAVING MACHINE UNATTENDED, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, LOWER BOOM,

SET PARKING BRAKE,AND SHUT-OFF ENGINE CHOCK

WHEELS IF MACHINE MUST PARK ON AN INCLINE

17 LEVEL MACHINE BEFORE LIFTING ANY LOAD ABOVE 4

FEET (IF EQUIPPED WITH FRAME LEVELING)

18 OPERATOR PROTECTION (SUCH AS HARD HATS, SAFETY

GLASSES, AND/OR HEARING PROTECTION) SHOULD BE

WORN WHEN JOB CONDITIONS WARRANT ALWAYS USE

SEAT BELT

19 IMPROPER USE OF MACHINE COULD RESULT IN MACHINE

TIPPING OVER IF MACHINE STARTS TO TIP OVER, DO

NOT LEAVE OPERATORS SEAT LEAN AWAY FROM TIP &

BRACE YOURSELF

20 KEEP MIRROR(S) CLEAN AND PROPERLY ADJUSTED

OBJECTS IN MIRROR ARE CLOSER THAN THEY APPEAR

9055-3028 REV A

FOR SAFE OPERATION OF MACHINE AND TO MINIMIZE RISK OF

SERIOUS INJURY, READ AND OBSERVE THE FOLLOWING:

9150-3102 REV -

Courtesy of Crane.Market