. OPERATION OF THE CONTROL SYSTEM

Graf UK Ltd

4OPERATION OF THE CONTROL SYSTEM

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor allows for the

set-up of operating parameters, the display of operating conditions and the query of system parameters as well as the

programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The settings are then

confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automatically after

2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter operator- specific

settings.

6. Service level: A password-protected service level can be accessed from the operator level using an additional code.

This level is reserved for trained personnel. Here adjustments or changes can be made and diagnostic data is retrieved.

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start time in

accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be suppressed for the set

period of time. Only one holiday cycle with greatly reduced activity takes place at this time. During this time, no treated

wastewater will be removed, as there should be no supply.

4. Operation of the Control System

24 / 57

4. Operation of the Control System

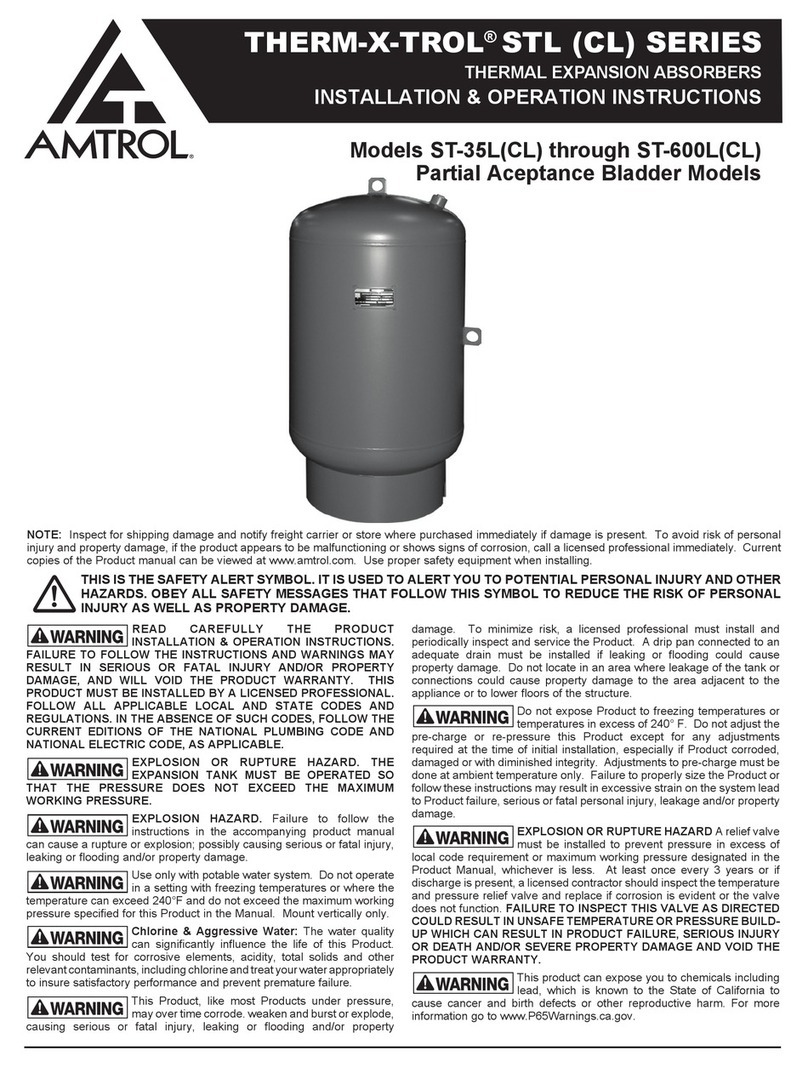

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor

allows for the set-up of operating parameters, the display of operating conditions and the query of system

parameters as well as the programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The set-

tings are then confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automati-

cally after 2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of

error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter oper-

ator-specific settings.

6. Service level: A password-protected service level can be accessed from the operator level using an

additional code. This level is reserved for trained personnel. Here adjustments or changes can be

made and diagnostic data is retrieved.

Figure 2: view of the operating unit

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start

time in accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be sup-

pressed for the set period of time. Only one holiday cycle with greatly reduced activity takes place at this

time. During this time, no treated wastewater will be removed, as there should be no supply.

4. Operation of the Control System

24 / 57

4. Operation of the Control System

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor

allows for the set-up of operating parameters, the display of operating conditions and the query of system

parameters as well as the programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The set-

tings are then confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automati-

cally after 2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of

error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter oper-

ator-specific settings.

6. Service level: A password-protected service level can be accessed from the operator level using an

additional code. This level is reserved for trained personnel. Here adjustments or changes can be

made and diagnostic data is retrieved.

Figure 2: view of the operating unit

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start

time in accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be sup-

pressed for the set period of time. Only one holiday cycle with greatly reduced activity takes place at this

time. During this time, no treated wastewater will be removed, as there should be no supply.

4. Operation of the Control System

24 / 57

4. Operation of the Control System

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor

allows for the set-up of operating parameters, the display of operating conditions and the query of system

parameters as well as the programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The set-

tings are then confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automati-

cally after 2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of

error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter oper-

ator-specific settings.

6. Service level: A password-protected service level can be accessed from the operator level using an

additional code. This level is reserved for trained personnel. Here adjustments or changes can be

made and diagnostic data is retrieved.

Figure 2: view of the operating unit

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start

time in accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be sup-

pressed for the set period of time. Only one holiday cycle with greatly reduced activity takes place at this

time. During this time, no treated wastewater will be removed, as there should be no supply.

4. Operation of the Control System

24 / 57

4. Operation of the Control System

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor

allows for the set-up of operating parameters, the display of operating conditions and the query of system

parameters as well as the programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The set-

tings are then confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automati-

cally after 2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of

error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter oper-

ator-specific settings.

6. Service level: A password-protected service level can be accessed from the operator level using an

additional code. This level is reserved for trained personnel. Here adjustments or changes can be

made and diagnostic data is retrieved.

Figure 2: view of the operating unit

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start

time in accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be sup-

pressed for the set period of time. Only one holiday cycle with greatly reduced activity takes place at this

time. During this time, no treated wastewater will be removed, as there should be no supply.

4. Operation of the Control System

24 / 57

4. Operation of the Control System

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor

allows for the set-up of operating parameters, the display of operating conditions and the query of system

parameters as well as the programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The set-

tings are then confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automati-

cally after 2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of

error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter oper-

ator-specific settings.

6. Service level: A password-protected service level can be accessed from the operator level using an

additional code. This level is reserved for trained personnel. Here adjustments or changes can be

made and diagnostic data is retrieved.

Figure 2: view of the operating unit

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start

time in accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be sup-

pressed for the set period of time. Only one holiday cycle with greatly reduced activity takes place at this

time. During this time, no treated wastewater will be removed, as there should be no supply.

Figure 2: View of the operating unit