Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN599500AV • 20 October 2020

Page 4 of 20

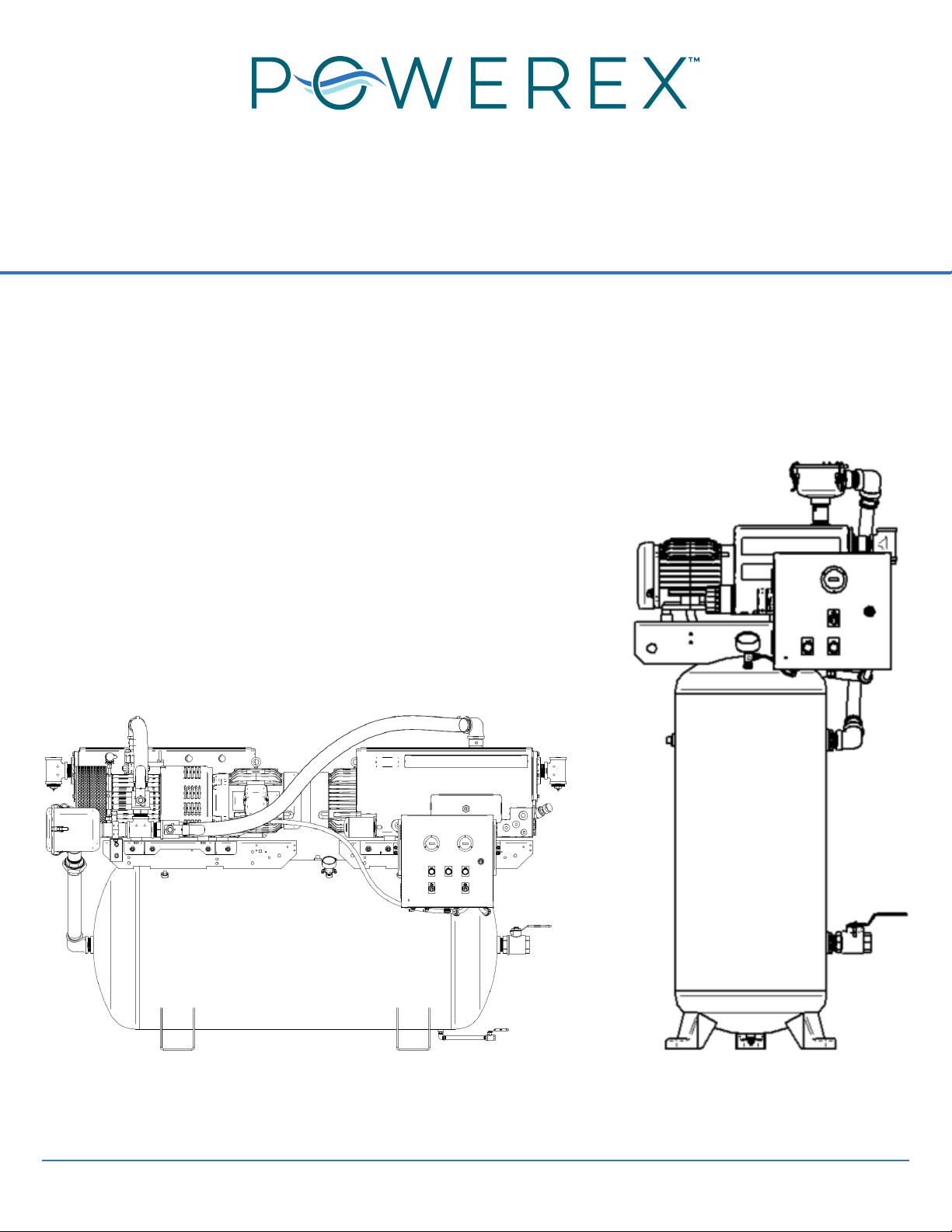

Industrial Vacuum Tankmount Systems

Operating & Maintenance Manual

Description

Powerex vacuum tank mount simplex/duplex units

are designed to provide vacuum for process, molding,

packaging, printing and other similar facilities. Vacuum

tank mount systems can be used for a variety of

air or inert gas. Some water vapor may be contained in

No liquid must reach the vacuum system. The system

be separated and collected upstream of the Powerex

system and disposed of as needed. The exhaust stream

of the vacuum pump will contain the process gas and

may contain some trace oil from the pump operation.

the room can be ventilated if suitable.

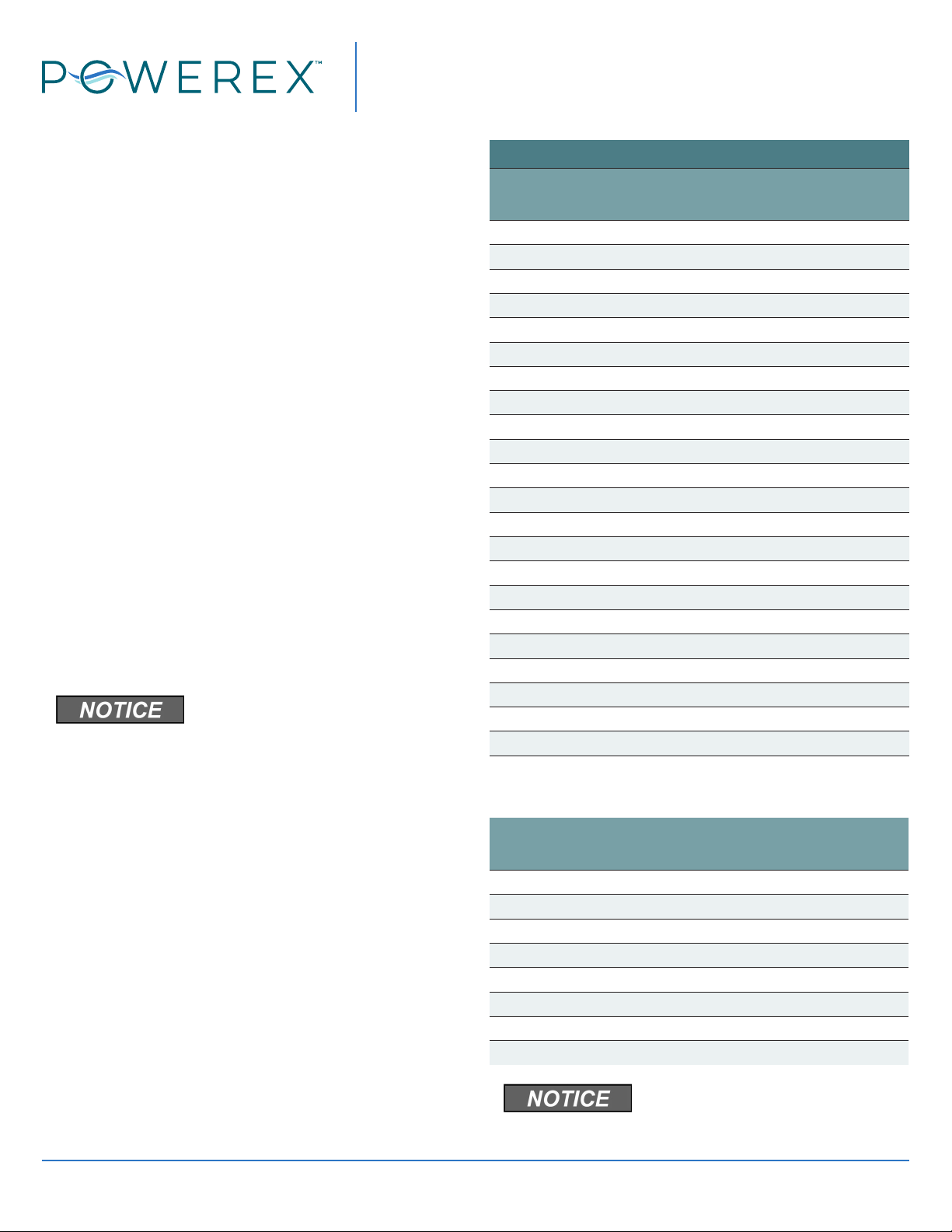

Specications

Product IBVS/IBVD

Operating Voltages 208V, 230V, 460V

Control Panel

Motor TEFC Electric Motor

Tank ASME Rated for 200 psi MAWP/

Full Vacuum

Drive Direct

Inlet and Exhaust

Vacuum Connections

1.5 HP to 4.6 HP – 1 1/4 inch

5 HP to 10 HP – 2 inch

Safety Guidelines

This manual contains information that is very

important to know and understand. This information

is provided for SAFETY and to PREVENT EQUIPMENT

the following symbols..

Danger indicates an imminently

Warning indicates a potentially

Caution indicates a potentially

Notice indicates important

information, that if not followed,

may cause damage to equipment.

NOTE: Note indicates information that requires

special attention.

Components

Vacuum Tankmount Systems

The IBVS and IBVD (Vacuum Tankmount Simplex

and Duplex) systems consist of one or two rotary vane

vacuum pumps that can be operated independently or

in tandem. The system will operate the pump or pumps

to maintain the vacuum level determined by the control

panel settings. The duplex systems control panel

automatically sequences the pumps to maintain equal

run time on each pump. The direct drive vacuum pump

is equipped with a continuous duty TEFC induction

motor. Maintenance on the rotary vane pump is

the pumps.

The pump or pumps draw air through a 10 micron

protection against leakage. A stainless steel protective

equipment on the pumps. The inlet screen protects the

pump from large particles entering the rotor/vane area.

The pumps have a built in gas ballast valve to help

prevent moisture accumulation.

Receiver Tank

The receiver tank is an ASME registered pressure

vessel rated for 200psig maximum allowable working

pressure and suitable for full vacuum. It is installed in

is not intended to be a liquid collector, and failure to

or IBVD system may damage the pumps and void

warranty. A vacuum gauge is installed and a manual

tank drain valve is included.

Factory installed receiver is used for

vacuum capacity only and is NOT a

collection receiver.

Never drill holes in, or perform any

welding on tanks or use them

beyond the rated pressure settings.