3 / 54

Dear Sir/Madam,

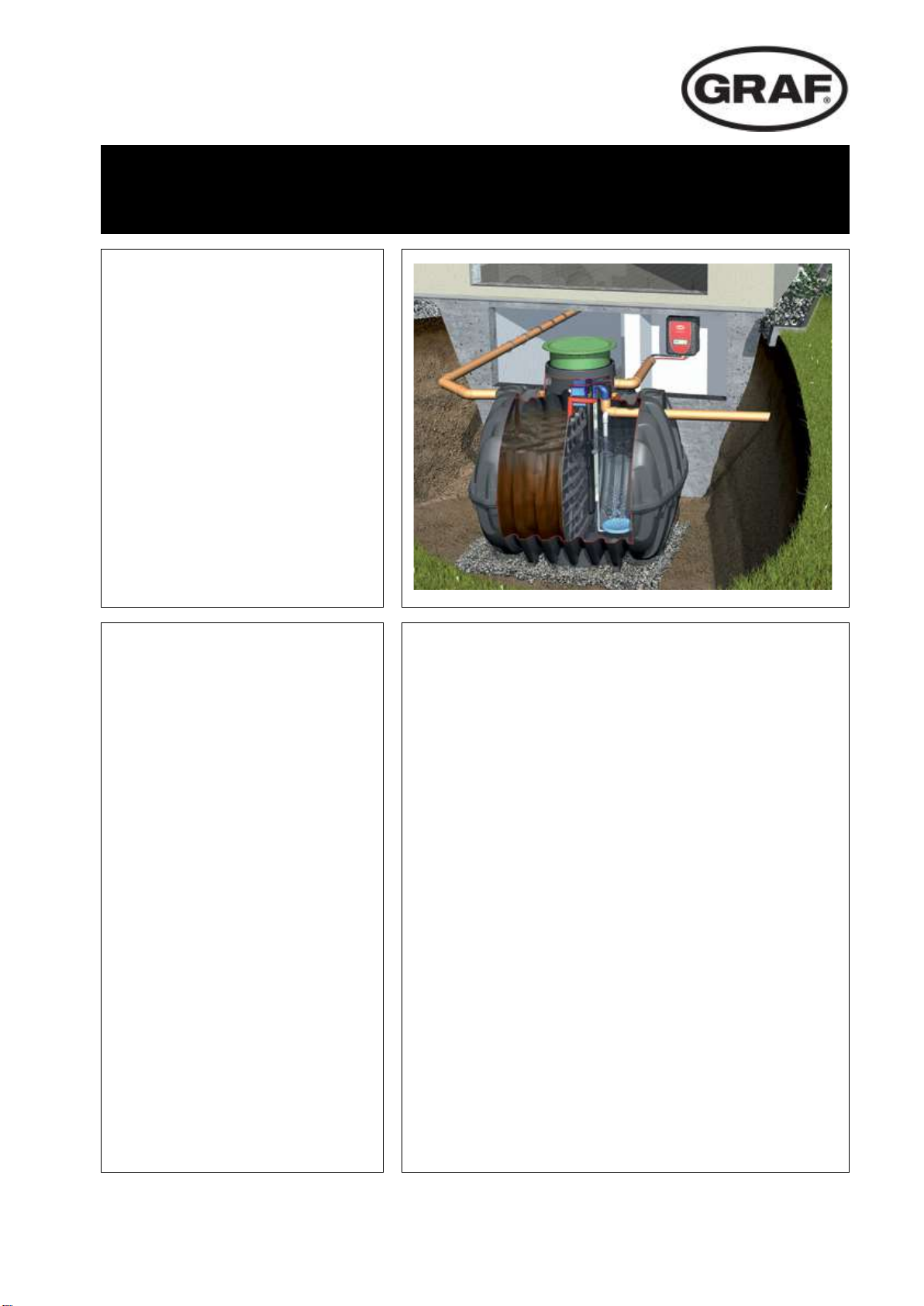

We are delighted that you have chosen to buy a modern Klaro Easy SBR system. Klaro Easy

is a quality product that as a complete system meets the requirements of DIN EN 12566-3 and

DIN 4261-1, making it a fully biological small wastewater treatment system. Below you will find

some important information for safely operating your system for a long time to come.

The SBR system is designed to receive all domestic wastewater. Other wastewater, e.g.

from restaurants and / or commercial premises etc., may only be received if this was

specified and taken into account in the system's design.

Biocides, toxic substances or substances which are not biocompatible must not enter

this system because they hinder bacteria important to wastewater cleaning and cause

problems in the biological process (detailed information is provided on the following pag-

es).

To meet official cleaning requirements, it is essential that the system is operated

in accordance with our operating and maintenance instructions. You will find these

instructions on the following pages.

We also ask you to read the following information carefully:

The internal control cabinet must be installed in a dry, well ventilated room (cellar or

garage).

External control cabinets should be located as much in the shade as possible to prevent

them from overheating in the summer.

At all times ensure that the cabinet, especially its ventilation apertures, are not covered

and are freely accessible for maintenance work.

EPP control cabinet: Ventilation apertures on the front and top

Internal control cabinet: Ventilation apertures on the sides

External control cabinet: Ventilation apertures on the rear

The power supply must be ensured at all times. Please ensure that the fuse on the con-

trol cabinet is sufficient (16 A). Additional electrical fixtures on the same fuse may dis-

rupt operation.

Otto Graf GmbH in Teningen