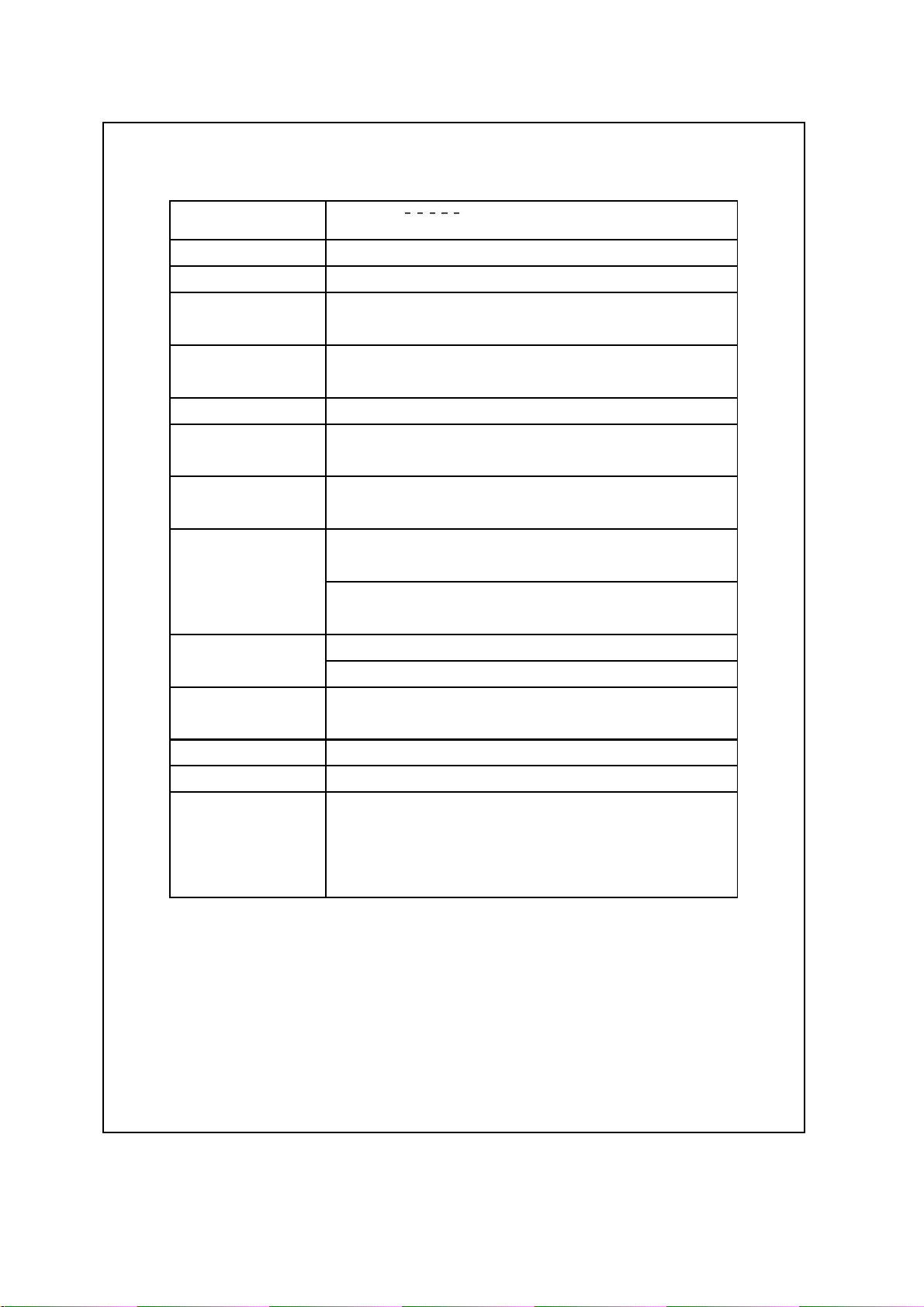

TABLE OF CONTENTS

1. FEATURES................................................................1

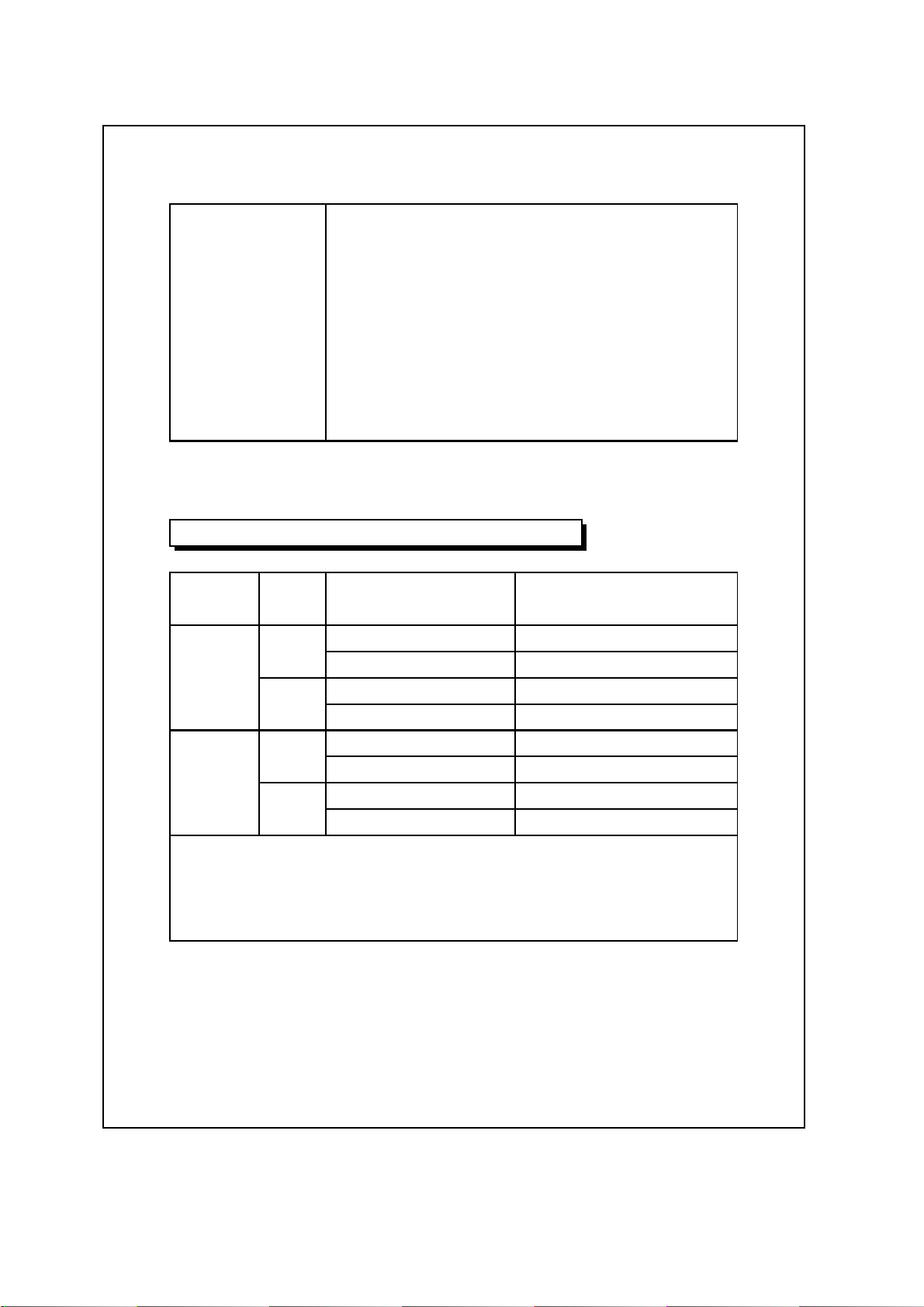

2. SPECIFICATIONS......................................................2

2-1 General Specifications..........................................2

2-2 Electrical Specifications........................................4

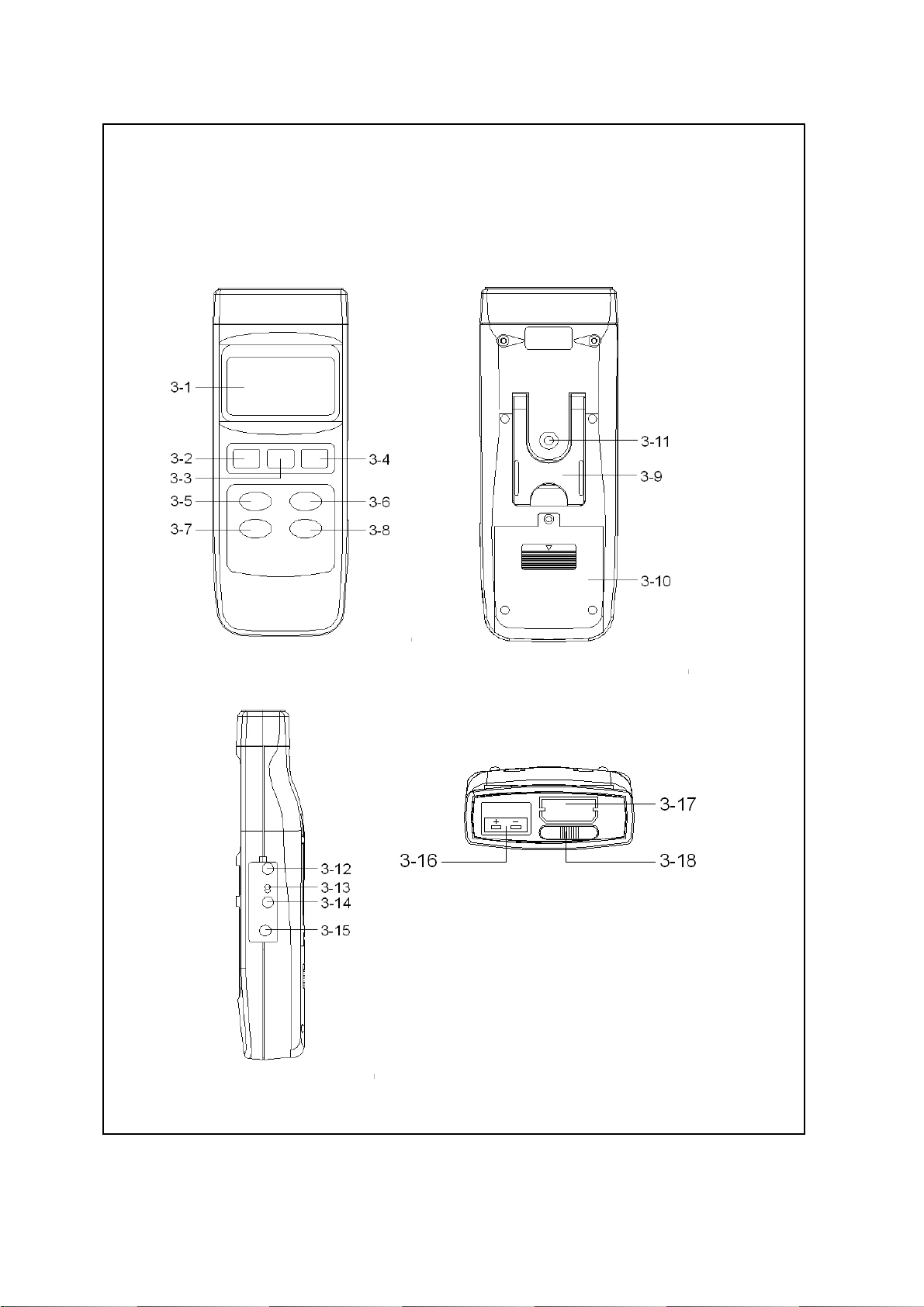

3. FRONT PANEL DESCRIPTION.....................................6

4. GENERAL MEASURING PROCEDURE...........................8

4-1 Thermocouple ( Type K/J ) Thermometer

Measurement......................................................8

4-2 Pt 100 ohm Measurement.................................... 9

4-3 Infrared Thermometer Measurement....................

9

4-4 Data Hold...........................................................

10

4-5 Data Record (Max., Min. reading).........................10

4-6 Data Logger........................................................11

5. ADVANCED ADJUSTMENT PROCEDURE...................... 13

5-1 Check Memory Space..........................................

14

5-2 Clear Memory......................................................15

5-3 Date/Time Setting...............................................

15

5-4 Sample Time Setting............................................15

5-5 Auto Power Off Default Setting.............................16

5-6 Temp. Unit Default Setting...................................16

5-7 Escape from the SETTING function.......................16

6. HOW TO SEND THE DATA OUT FROM THE METER.....

17

7. RS232 PC SERIAL INTERFACE...................................

20

8. BATTERY REPLACEMENT...........................................22

9. Type K/J OFFSET ADJUSTMENT.................................22

10. SYSTEM RESET.......................................................24

11. OPTIONAL ACCESSORIES........................................25