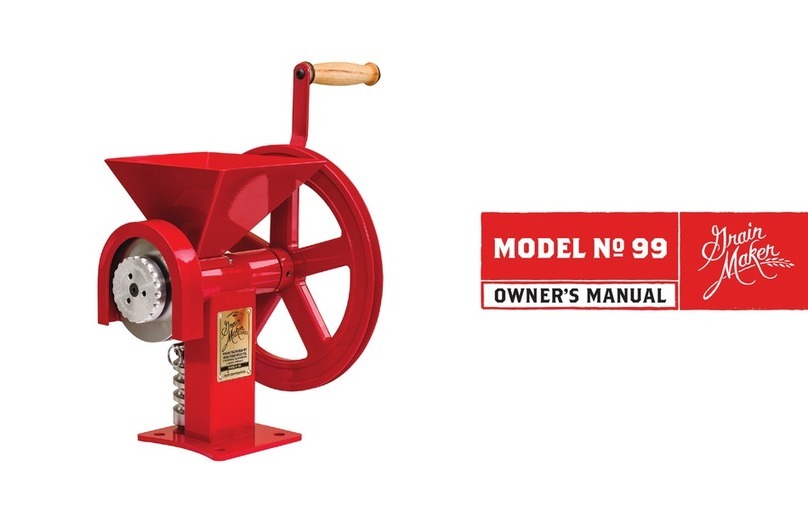

The GrainMaker®Roller/Flaker/Crusher Mill

comes partially assembled. You will need to

attach the handle to the pulley with the

supplied hex wrenches. This completes

the assembly. Before operating this mill,

you will need to secure it to your work

surface either by bolting or using the clamp.

Protect yourself and your Mill! Get in the

habit of using the hopper guard every time

you mill. Grain should be the only item ever

placed in the mill.

Bin or Chute

The mill comes with a ten-cup capacity

stainless steel bin. When larger quantities

are being produced, you can mount the

mill on the edge of a work surface, and use

the stainless steel chute. To use the chute,

remove the ten cup bin, then slide in the

chute and hook it onto the bolts located

on the inside of the frame. Milled grain can

now ow easily down the chute into a pail

or bag.

Adjusting the Thickness

The mill is equipped with dual drive gears

and a unique pull and turn self locking

knob. The knob is spring loaded with

multiple positions for a ake or crack

thickness. This simply adjusts the width

between the rollers. To change the gap

between the rollers, simply grasp the knob

and pull it out away from the body of the

mill until you can turn it to one of the other

settings. Once you have chosen a

thickness, close the slide at the bottom of

the hopper. Ensure the hopper guard is in

the hopper, ll with the grain of your choice

and begin rolling, making sure you are

turning the handle clockwise.

Using the Roller/Flaker/Crusher

Open the hopper feed slide until grain falls

down into the rollers. Roll a small amount

to see if it is the desired thickness. If the

nished product is too thin, simply move

to the next larger number, if it is too thick,

close the hopper feed slide and run the

rest of the material through that has already

fallen into the rollers, then adjust the dial to

the next smaller number. Repeat until you

have your desired thickness. When using

this mill with the settings between 1-3,

it may be necessary to motorize the mill.

HINT: Most grains roll better if they are

moistened a little. The night before you

plan to mill, add one tablespoon of water

to a quart of oat groats. Cover and let rest

at least a few hours or overnight and they

will roll atter and thinner.

MOTORIZATION Tips

The mill can be used without gear

reduction. (Since the mill is flaking,

rolling or crushing, there is no need to

reduce the speed of the mill as you do

when milling flour.) Just secure a v-belt

to the fly-wheel on the mill and attach it

INTRODUCTION

SET-UP

Close the hopper feed slide if there is grain

in it. Locate the two black thumbscrews,

unscrew the two thumbscrews, then lift

the hopper assembly from the body of the

mill. Make sure that all hair, loose clothing,

ngers etc. are kept out of the rollers. Place

the hopper on a clean, at surface and

remove the scraper bars. You can then use

a brush, or even a wire brush if need be to

clean the rollers. The rollers are steel;

you will not damage them. Except when

cleaning, only grain should come in contact

with the rollers. When nished cleaning,

replace the scraper bars, set the hopper

back on the mill and tighten the screws.

CAUTION: IF YOU HAVE A MOTOR CONNECTED

TO YOUR MILL, YOU MUST UNPLUG THE

CORD BEFORE YOU CLEAN YOUR MILL.

IT IS EXTREMELY IMPORTANT AND

NECESSARY THAT ALL HAIR, FINGERS,

LOOSE CLOTHING ETC. BE KEPT AWAY

FROM THE ROLLERS ONCE THE HOPPER

IS REMOVED. THESE ROLLERS WILL BE

EXPOSED DURING THE CLEANING PROCESS.

NEVER LEAVE MILL UNATTENDED DURING

THE CLEANING PROCESS.

CLEANING

to a motor. We recommend a 56 Frame

1 HP motor 1800 RPM’s or lower.

Place protective guarding around all belts,

pulleys and areas where ngers, loose

clothing and hair may get caught or

entangled. Serious injury, dismemberment

or death could occur.

HINT: We recommend this motor:

1 HP 115/230 Volt AC 1725 RPM Leeson

Farm Duty Motor, Item Number: 10-1026

SurplusCenter.com