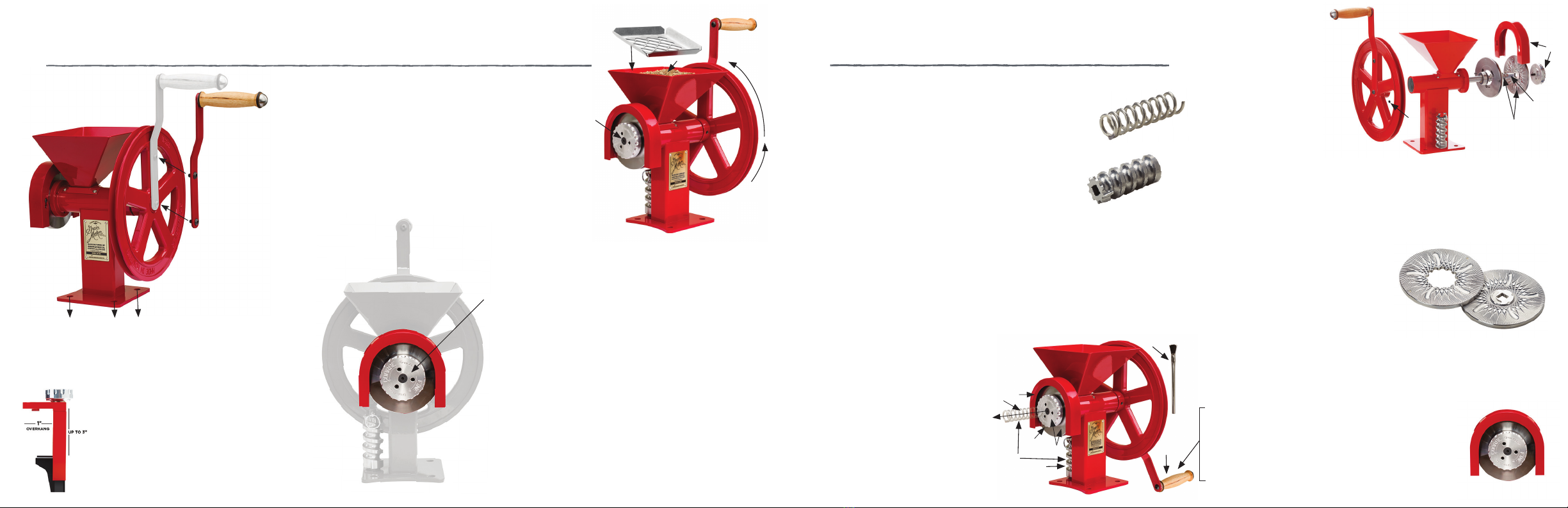

Coil auger Each mill is shipped with the coil auger already

inserted in the mill. This auger looks like a big spring and

is used to grind smaller grains. The coil auger must

be inserted with the at end rst - towards the mill.

GrainBreaker auger This auger is designed to break

larger media into smaller pieces while pushing it

into the grinding burrs for the nal grind. It must

be used for legumes, corn, coffee and nuts.

Changing the augers

A. Position the extension handle and grip to its lowest point.

B. Remove dust cover.

C. Hold the burrs together with one hand while turning the click

& lock adjustable knob counterclockwise with the other hand

until it is completely unscrewed.

D. Remove the front grinding burr. It is not necessary to remove

the stationary burr when changing the augers.

E. Pull the auger out.

F. Use the provided brush to sweep out

any remaining media left inside the tube.

G. Insert the desired auger and reverse

the steps above.

H. Store the other auger on the

storage post. The storage post

is shipped with blue protective

tape at the top to protect it

during shipping. You may

choose to remove it if desired.

setup

1. ATTACH THE EXTENSION HANDLE

A. Remove the bolts securing your

mill to the shipping board and

secure the handle using the large

Allen wrench. Place the rst bolt

furthest away from the wood

grip into the shaft.

B. Place the second bolt into

the tapped spoke of the

V-pulley ywheel.

3. BEGIN MILLING

A. Place the safety guard in the hopper.

B. Fill the hopper with grain.

C. Loosen the click and lock

adjustable knob as it has been

tightened for shipping.

D. Turn the extension handle clockwise.

4. FINE-TUNING

A. As the grain works into the burrs, tighten the

adjustable click & lock knob 1 to 2 clicks, then turn

the extension handle 3 to 4 times, test consistency

and repeat this process until you reach the

desired consistency.

B. Remember, making small adjustments of 1

to 2 clicks does change the consistency, but it

is necessary to turn the extension handle a couple

of times. Do not go by what is in your collection

container as this will have various consistencies

during this process. Do not overtighten. This will

not allow the media to ow as there needs to be

room between the grinding burrs to allow the

our to escape.

Note: When grinding grain into our, it is

normal to have more our accumulating on

one side of your container versus the other.

2. SECURE THE MILL

A. Bolt your mill down to your work surface

B. You may also use the GrainMaker clamp.

The mill must be secured.

mill details

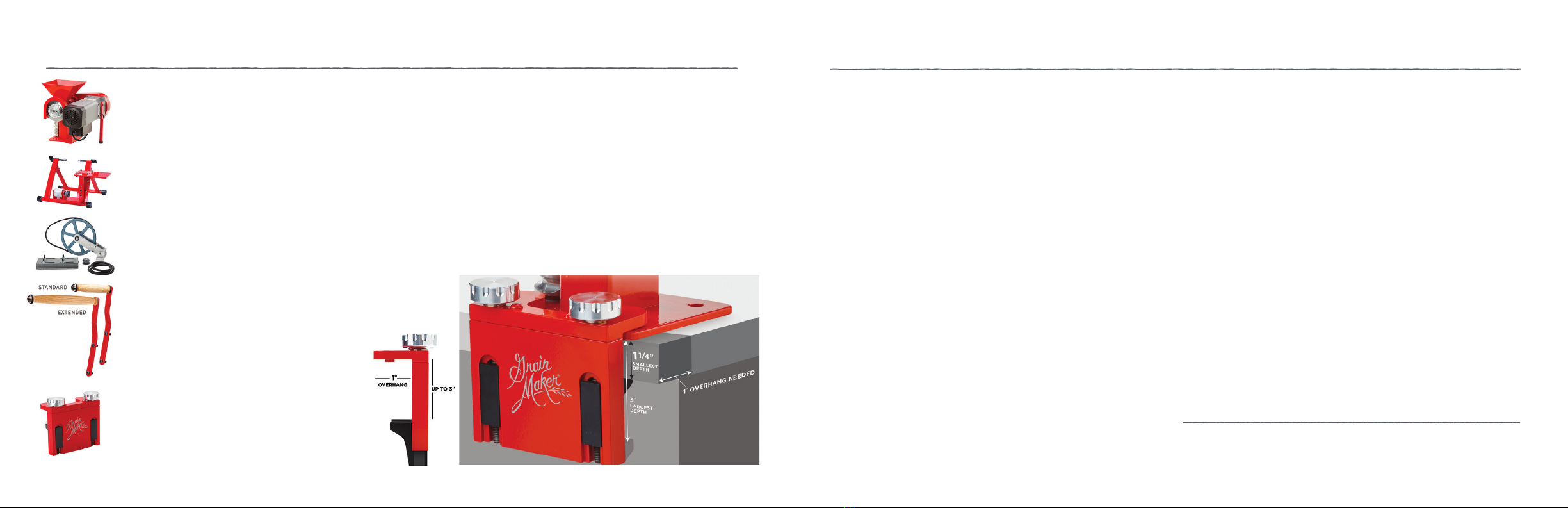

CUSTOM MOUNTING CLAMP (sold separately)

This custom machined heavy-duty clamp

needs 1” overhang clearance with a thickness

of up to 3”. This clamp is not ideal for those

with rounded or waterfall edge counters.

a

b

c

d

a

b

ab

c

d

a

b

e

F

H

c

d

G

Shaft and Bearing

ASSEMBLY Removal

A. Remove pulley v-belt

ywheel by loosening

the set screw.

B. Remove dust cover and

adjustment knob.

C. Remove rotating front burr and auger.

D. Use a rubber mallet or block of wood placed on the end of

the shaft where the adjustment knob (B) was and tap. The shaft

and bearing assembly will come out on the opposite end where

the pulley v-belt ywheel was.

Note: To replace, do the reverse of the above steps.

GRINDING BURRS

A. Over-tightening the grinding burrs

will not allow media to ow.

B. If the grinding burrs are hot, you may

have the knob too tight. This is common especially

when using your own motor and running it too fast.

CLICK & LOCK ADJUSTMENT KNOB

A. Loosening the knob: Larger gap between burrs = coarser grind.

B. Tightening the knob: Less space between burrs = ner grind.

Note: When you loosen the knob, position the

extension handle and grip to its lowest point. If

you fail to do this, the handle and grip will lose

resistance and rotate quickly towards the base

of the mill. This could harm your ngers or hands.