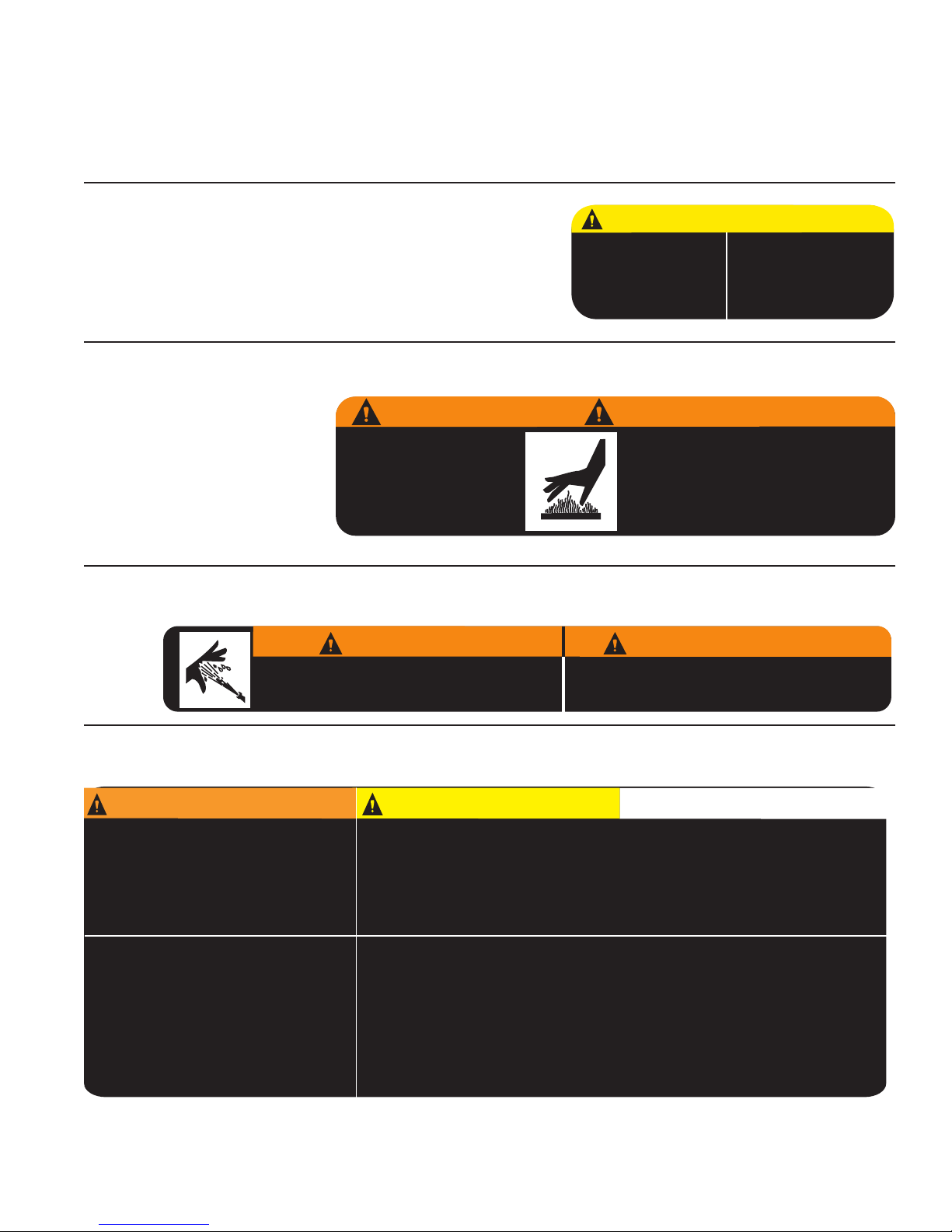

• RISK OF INJECTION OR SEVERE INJURY. KEEP CLEAR OF

NOZZLE DO NOT DIRECT SPRAY TOWARD ANY PERSON OR

SELF.

• RISK OF ASPHYXIATION. OUTDOOR USE ONLY REQUIRED.

• RISK OF FIRE. DO NOT SMOKE WHILE REFUELING.ALLOW TO

COOL TWO TO THREE MINUTES BEFORE REFUELING. DO NOT

OPERATE WHILE REFUELING.

• RISK OF ELECTROCUTION. DO NOT DIRECT SPRAY TOWARD

ANY ELECTRICAL CONNECTIONS, OUTLETS, OR POWER LINES.

• RISK OF EXPLOSION. DO NOT SPRAY FLAMMABLE LIQUIDS.

• TO REDUCE RISK OF INJURY: READ AND UNDERSTAND THE

OPERATION MANUAL AND ALL INSTRUCTIONS BEFORE

USING.

• STAY ALERT: HOLD ONTO GUN/WAND FIRMLY WITH BOTH

HANDS TO AVOID DANGEROUS KICKBACKS.

• ALWAYS WEAR EYE PROTECTION.

• DO NOT OVERREACH OR STAND ON UNSTABLE SUPPORT.

KEEP GOOD FOOTING AND BALANCE AT ALL TIMES.

• ALWAYS TURN ON WATER SUPPLY TO PUMP BEFORE

STARTING.

• PROTECT PUMP FROM FREEZING.

• ENGAGE TRIGGER SAFETY LOCK-OFF WHEN NOT IN USE.

• AFTER ENSURING ALL CONNECTIONS ARE SECURE, OPEN INLET

WATER SUPPLY COMPLETELY. DO NOT OPERATEWITHOUTWATER.DO

NOT USE WATER THAT IS OVER 125˚F. • WITH GUN LOCKED, REMOVE

NOZZLE. POINT GUN IN A SAFE DIRECTION. BRACEWAND SECURELY

TO AVOID RECOIL.SQUEEZETRIGGER OPEN. STEADY THE UNIT AND

START BY PULLING ON THE STARTER ROPE. • AFTER ENGINE IS

RUNNING, LOCK GUN AND INSERT DESIRED NOZZLE. POINT GUN IN A

SAFE DIRECTION. UNLOCK GUN AND SQUEEZETRIGGER TO SPRAY

AND RELEASETHETRIGGERTO STOP SPRAY. • AFTER STOPPINGTHE

ENGINE, ALWAYSTURN OFFWATER SUPPLY AND SQUEEZETRIGGER

TO RELEASE TRAPPED PRESSURE.

• RIESGO DE INYECCION O LESION SEVERA. MANTENGA LA

BOUILLA DESPEJADA. NO DIRIJA EL CHORRO HACIA PERSONA

ALUNA O HACIA USTED.

• RIESGO DE ASFIXIA: UNICAMENTE PARA USO EN EL EXTERIOR.

• RIESGO DE FUEGO: NO FUME MIENTRAS ESTE

REABASTECIMIENTO DE COMBUSTIBLE. PERMITA QUE EL

MOTOR SE ENFRIE DOS O TRES MINUTOS ANTES DEL

REABASTECIMIENTO. NO OPERE EL PRODUCTOR DURANTE EL

REABASTECIMIENTO.

• RIESGO DE ELECTROCUCION: NO DIRECTA EL CHORRO HACIA

CONEXIONES. ELECTRICAS.TOMAS DE CORRIENTE O LINEAS

DE ALIMENTACION DE CORRIENTE.

• RIESGO DE EXPLOSION: NO ROCIE LIQUIDOS INFLAMMABLES.

• RIESGO DE LESION: USE UNICAMENTE EQUIP CON

CLASIFICACION ADEDUADA.

• PARA REDUCIR EL RIESGO DE QUE OCURRAN LESIONS:

LEA Y ENTIENDA EL MANUAL DE OPERACIONY TODAS LAS

INSTRUCCIONES ANTE DE USAR EL PRODUCTO.

• PERMANIZCA ALERTA: SOSTENGA LA PISTOLA VARILLA

FIRMENMENTE CON AMBAS MANO PARA EVITAR GOLPES

DE RETROCESO PELIGROSOS.

• USE SIEMPRE PROTECCION OCULAR.

• NO SE EXTIENDA DEMASIADO O SE PARE EN UN APOYO

INESTABLE. MANTENGA UNA BUENA POSICIONY

BALANCE TODO EL TIEMPO.

• ANTES DE COMENZAR. ABRA SIENPRE EL SUMINSTRO DE

AGUA A LA BOMBA.

• PROTEJA LA OMBA DE LA CONGELACION.

• COLOQUE EL SUGURO DEL GATILLO EN LA POSICION

APAGADO CUANDO NO ESTE USANDO EL PRODUCTO.

• DISPUES DE ASEGURARSE QUE TODAS LAS CONEXIONES

ESTAN SEGUIRSE.ABRA LA ENTRADA DEL SUMINSTRO DE AGUA

COMPLETAMENT NO SE OPERE SIN AGUA. NO SE USE CON AGUA

CONTEMPERATURAS DE MAS DE 125˚F.

• CON LA PISTOLA ASEGURADA. REMUEVA LA BOQUILLA

APUNTANDO LA PISTOLA HACIA UNA DIRECCION SEGURA.

REFURESE LAVARA PARA EVITAR QUE RETROCEDA.APRIETE EL

GATILLO PARA ABRIRLO.MANTEGA LA UNIDAD QUIETA.Y COMIENZE

HALANDO FIRMEMENTE EN LA CUERDA DE INICIAR.

• DESPUES DE QUE EL MOTOR ESTE TRABAJANDO.ADJUSTE LA

BOQUILLA A LA POSICION DESEADA.APRIETE EL GATILLO PARA

ROCIARY SUELTELO PARA DETENER EL ROCIADO.

•

DESPUES DE DETENER EL MOTOR. CIERRE DIEMPRE EL

SUMINSTRO DEL AGUO AND APRIETE EL GATILLO PARA LIBERAR

LA PRESION ATRAPADA.

WARNING/ADVERTENCIA CAUTION/PRECAUCION OPERATION/OPERACION

34-0981-063099-E/S-ENG.