JIB

lndustries Inc. Material Safetv Data Sheet

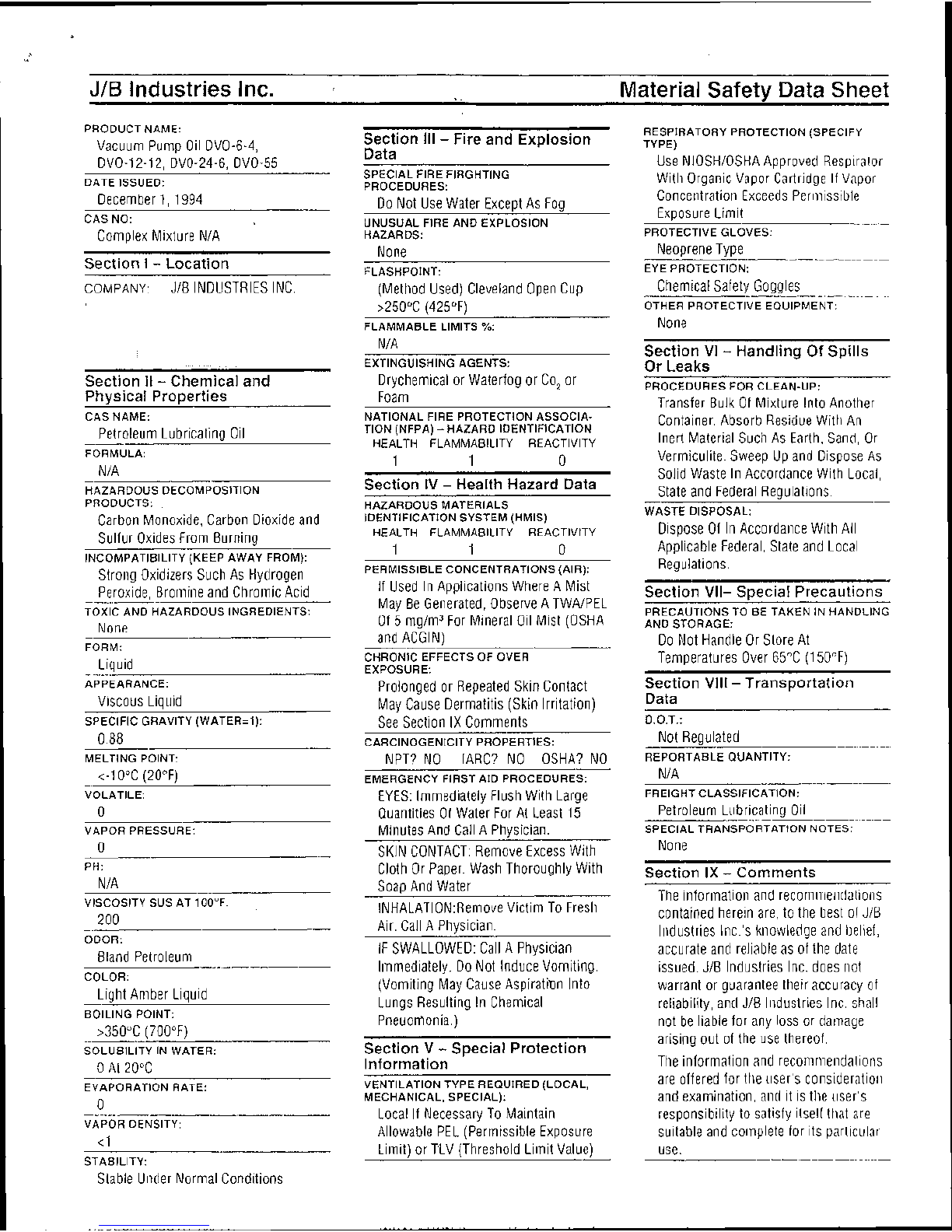

PRODUCT NAME:

Vacuum Pump Oil DVO-6-4,

Section

111

-

Fire

and

Explosion

Data

RESPIRATORY PROTECTION (SPECIFY

TYPE)

Use NIOSHIOSHA Approved Resp~rator

With Organic Vapor Cartridge If Vapor

Conceritratioli Exceeds Perlilissible

Ex~osureLirnit

DVO-12-12, DVO-24-6, DVO-55

DATE ISSUED: SPECIAL FlRE FlRGHTlNG

PROCEDURES:

December 1, I994

CAS NO:

Do Not Use Water Exceot As Foa

UNUSUAL FlRE AND EXPLOSION

HAZARDS:

None

Complex Mixture NIA

PROTECTIVE GLOVES:

Neo~reneTVD~

Section

I

-

Location

COMPANY.

JIB INDUSTRIES INC.

EYE PROTECTION:

Chemical Safety Goggles

FLASHPOINT:

(Method Used) Cleveland Open Cup

>250°C (425°F)

OTHER PROTECTIVE EQUfPMENT:

None

Section

VI

-

Handling

Of

Spills

Or

Leaks

FLAMMABLE LIMITS

%:

NIA

-

--

Section

II

-

Chemical

and

Phvsical Pro~erties

EXTINGUISHING AGENTS:

Drychemical or Waterfog or Co, or

Foam

PROCEDURES FOR CLEAN-UP:

Transfer Bulk Of Mixture lnto Anotlie~

CAS NAME:

Petroleum Lubricating Oil

FORMULA:

N/A

NATIONAL FlRE PROTECTION ASSOCIA-

TION (NFPA)

-

HAZARD IDENTIFICATION

Container. Absorb Residue With Ari

HEALTH FLAMMABILITY REACTIVITY

Inert Material Such AS Earth, Sand, Or

1

1

0

Vermiculite. Sweep Up and Dispose As

Solid Waste In Accordance With Local,

Section

IV

-

Health

Hazard

Data

State and Federal Reaulatioiis.

HAZARDOUS DECOMPOSITION

PRODUCTS:

Carbon Monoxide, Carbon Dioxide and

Sulfur Oxides From Burning

INCOMPATIBILITY (KEEP AWAY FROM):

Strong Oxidizers Such As Hydrogen

Peroxide, Bromine and Chromic Acid

HAZARDOUS MATERIALS

IDENTIFICATION SYSTEM (HMIS) WASTE DISPOSAL:

HEALTH

FLAMMABILITY

REACTIVITY

Dispose Of In Accordalice Witti All

1

1

0 Applicable Federal, State and Local

PERMISSIBLE

CONCENTRATIONS

(AIR):

Regulations.

If Used In Applications Where

A

Miit

Section

VII-

Special

Precautions

May

Be

Observe

A

TWAIPEL

PRECAUTIONSTO BETAKEN

IN

HANDLING

Of

5

mg/m3For Mineral Oil Mist (OSHA

AND

STORAGE:

TOXIC AND HAZARDOUS INGREDIENTS:

None

and ACGIN)

--

CHRONIC EFFECTS OF OVER

EXPOSURE:

Prolonged or Repeated Skin Contact

May Cause Dermatitis (Skin Irritation)

See Section IX Comments

CARCINOGENICITY PROPERTIES:

NPT? NO IARC? NO OSHA? NO

--

EMERGENCY FIRST AID PROCEDURES:

EYES: Immediately Flush With Large

Quantities Of Water For At Least 15

Minutes And Call A Physician.

SKIN CONTACT: Remove Excess With

Cloth Or Paper. Wash Thoroughly With

Soap And Water

INHALATI0N:Remove Victim To Fresh

Air. Call A Physician.

IF SWALLOWED: Call A Physician

Immediately.

Do Not Induce Vomiting.

(Vomiting May Cause AspiratiDn lnto

Lungs Resulting In Chemical

Pneuomonia.)

Do Not Handle Or Store At

Teniperatures Over 65°C (I50°F)

Section

Vlll

-

Transportation

Data

FORM:

Liouid

APPEARANCE:

Viscous Liq~rid

SPECIFIC GRAVITY (WATER=l): D.O.T.:

Not Regulatecl

-

----

REPORTABLE QUANTITY:

NIA

MELTING POINT:

-

<-I0°C (20°F)

VOLATILE: FREIGHT CLASSIFICATION:

Petroleum Lubricatinu Oil

0

VAPOR PRESSURE:

n

SPECIAL TRANSPORTATION NOTES:

None

Section

IX

-

Comments

PH:

N/A The information and recom~iierirlat~o~ls

contained herein are, to the best of JIB

llidustries Iric.'sknowledge and belief,

accurate ancl reliable as of the date

issued.JIB Industries Inc. does not

warrant or guarantee their accuracy of

reliability, and JIB Industries Inc,sliall

not be liable for ariy loss or ria~nage

VISCOSITY SUS AT 100°F.

200

ODOR:

Bland Petroleurn

COLOR:

Light Aniber Liquid

BOILING POINT:

>350°C (700°F) arising out of the use thereof.

Section

V

-

Special

Protection

Information

The inforniation and recornmendations

SOLUBILITY IN WATER:

0

At 20°C

VENTILATION TYPE REQUIRED (LOCAL,

are offered for the user's consideratioil

MECHANICAL,

SPECIAL):

and examination, and it is tile user's

EVAPORATION RATE:

0

--

VAPOR DENSITY:

<1

Local If Necessary To Maintain responsibility to satisfy itself that are

Allowable PEL (Permissible Exposure suitable and complete for its particirlar

Limit) or T'LV (Threshold Litnit Value) use.

-

-

.-

-

-

--

STABILITY:

Stable Urider Normal Coriditioris