03

GRANBOCOMMERCIAL ULTRASONIC CLEANER

Ultrasonic application description

The standard ultrasonic cleaners adopt high quality stainless steel plate with strong

corrosion resistance and long lifespan, transducers with advanced connection sticking

technology, high electroacoustic conversion efficiency and strong ultrasonic output,

also equipped with automatic constant temperature heating device. Temperature

range: 20-80℃.

Suit for varies industries and objects cleaning, such as precision electronic parts,

eyeglasses & clock parts, optical glass parts, hardware, jewelry, semiconductor silicon

wafer, printer inkjet, medical instruments and electroplate parts etc.

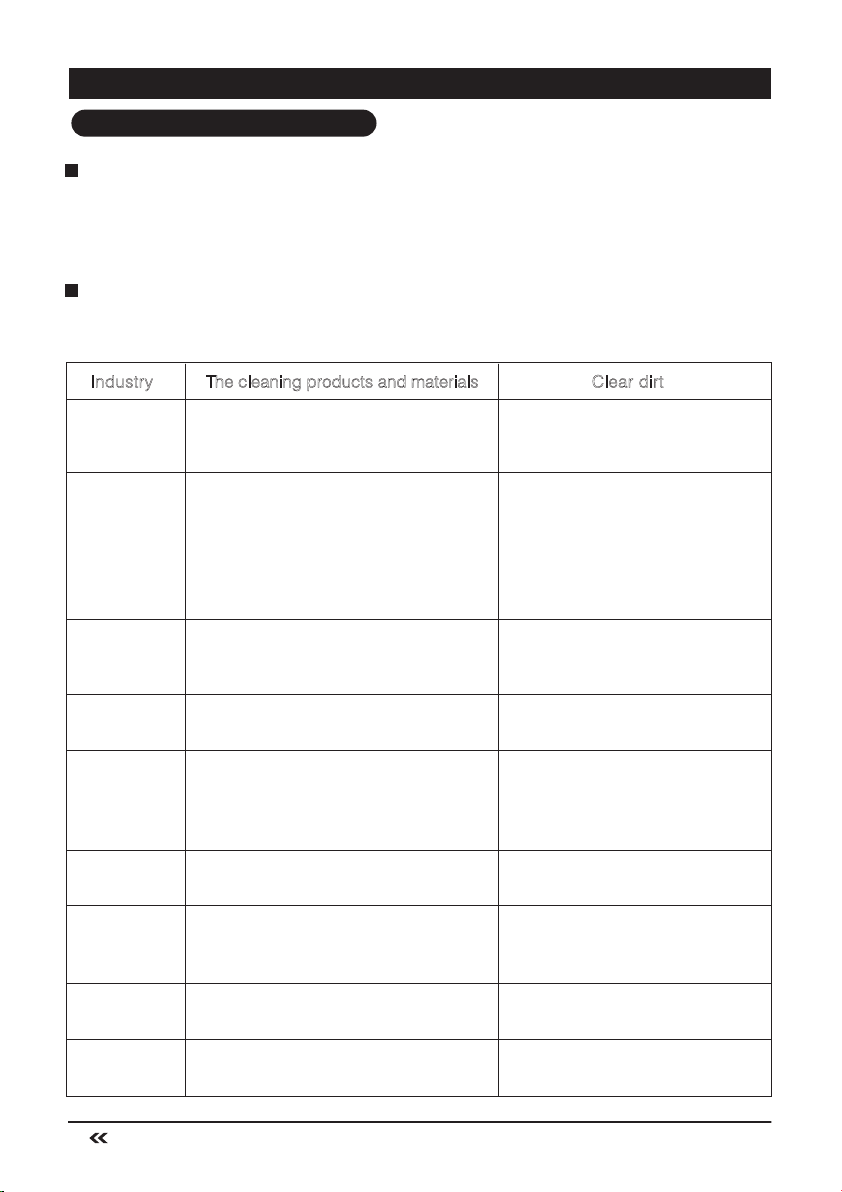

Industry The cleaning products and materials Clear dirt

Semi-conductor

Electrical&

electronic

machine

Precision

machine

Optical device

Medical

instrument

Electroplate

Car parts

Chemical fiber

Hardware&

machinery

parts

Integrated circuit, power tube ,silicon wafer,

diode, lead frame, capillary, tray, etc.

Tube parts, cathode ray tube, printed circuit

board,quartzparts ,electronic components ,

telephone switching equipment, speaker

components, power meter, LCD glass, core

iron parts, computer floppy disk, video parts,

head, photo die mask, etc.

Hards, etching oil, polishing wax, dust

particles, etc,

Finger print, powder, cutting oil, stamping

oil, iron filings, polish-ing materials, walnut

powder, polishing wax, resin, dust, etc.

Bearing, sewing machine parts, typewriter,

textile ,machine, optical mechanical device,

gas valve, watches cameras, metal filter.

Glasses, lens, prism, optical lens, filter lens,

glass device, film, optical fiber, etc.

Bearing, gear, ball, metal shaft parts, tools,

adjustable valve and cylinder parts, burner,

compressors, hydraulic press, gun and

ultracentrifuge, city water faucet, etc

Medical instrument, denture, etc.

Galvanized parts, mold, stamping parts, etc.

Piston ring, carburetor, flow meter housing,

compressor shell, electrical components, etc.

Chemical or artificial fiber nozzle filter protector

chemical fiber texture, etc.

Machine cutting oil, iron filings, olishing

powder, finger print, oil, grease, dirt, etc

Plastic resin, paraffin, finger printing, etc.

Cutting oil, iron filings, grease, polishing

powder ,finger printing and so on.

Iron filings. Polishing powder, oil,

stamping oil, dirt, etc.

Polishing scrap iron, oil, black iron

shell, rust, oxidation shell, scrap iron,

polishing powder, stamping oil, dirt, etc.

Iron filings, polishing powder, oil

stamping oil, dirt etc.

Chemical colloid, glue, and other solid

material. dust. Etc.