H22 Panel Radiators

1. Pensotti radiators are manufactured using cold rolled steel and can only be installed in forced

circulation, closed loop, hydronic heating systems.

2. Series loop piping is not recommended. Homerun, 2 pipe reverse return, 2 pipe direct return and

1 pipe monoflo piping systems are preferred.

3. Pensotti H22 and V20 radiators are supplied with hanging brackets, manual air vent and one

plug.

4. Do not over pressurize the system. Maximum operating pressure is 56 psi.

5. Radiators can be installed in any closed loop hydronic system with operating temperatures up to

230 degrees Fahrenheit.

6. Important: Do not install in gravity hot water or steam systems.

7. Each radiator must be vented individually.

8. Air removal from each radiator will need to be completed upon the initial fill of the system and

periodically during the heating season to assure proper operation and comfort.

9. Air removal from the system should be done while it is in a ‘static’ state (circulators not

operating).

10. Proper air elimination will ensure adequate water flow through the radiators.

11. Radiators expand when heated. The expansion rate is .015” per linear foot when heated to 210

degrees Fahrenheit. Drilled holes and piping connected to the radiator must be able to

compensate for this expansion.

12. Swing joints in the piping or flexible piping materials, are two easy ways of dealing with radiator

expansion and the noises it can create.

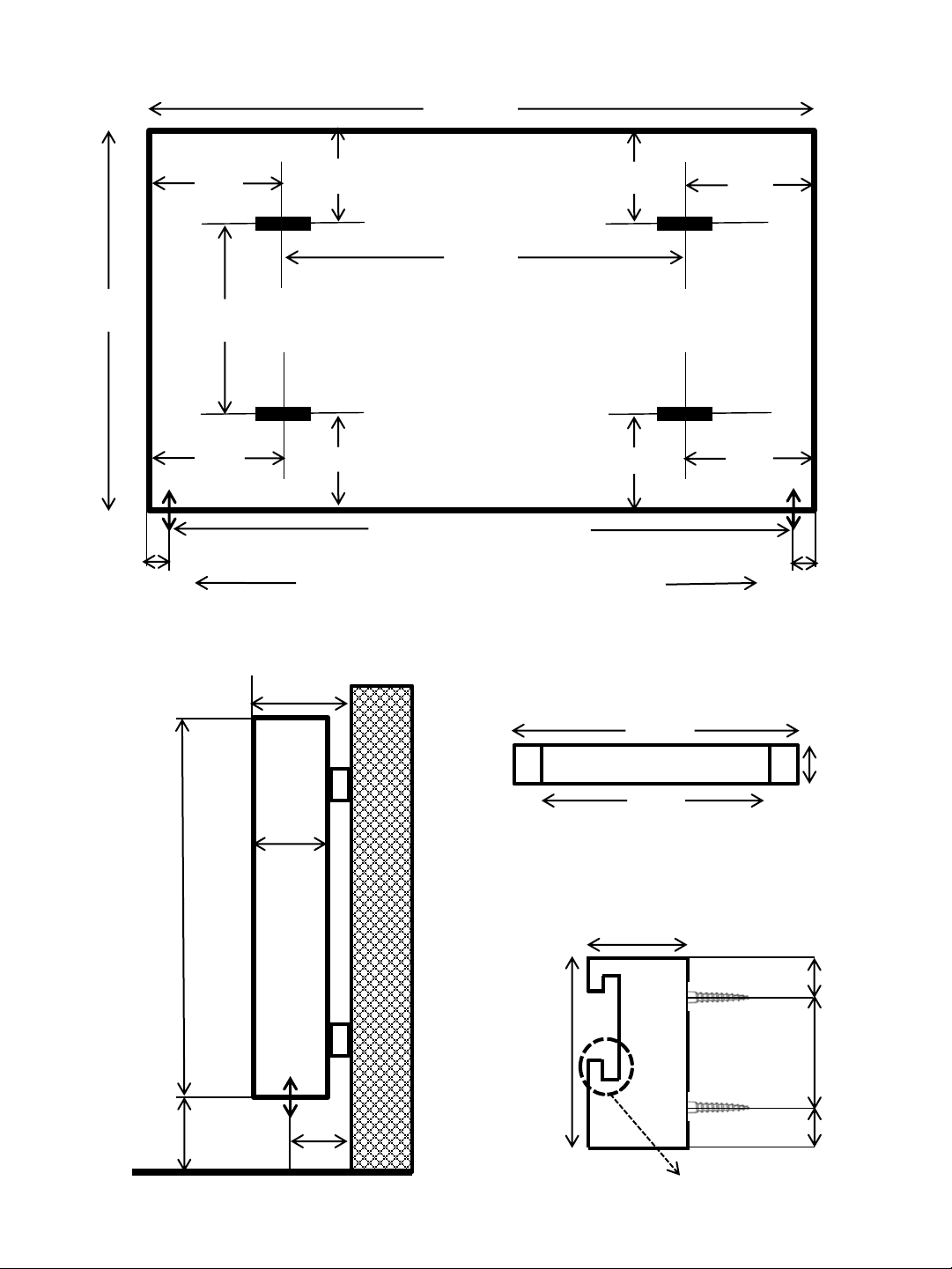

13. Always use all the hanging brackets supplied with each radiator.

14. Hanging brackets must be secured to wall studs or proper wall backing material with

appropriately sized and strength fasteners.

15. Surface temperature of the radiator will be equal to the temperature of the water flowing

through it. When installed on high temperature systems use proper precautions with infants and

toddlers.

16. Antifreeze use is permitted. Always refer to the boiler manufacturer’s recommendations

regarding type and dilution percentage.

17. Heating system water treatment is strongly suggested.

18. Do not install Pensotti radiators in harsh or caustic environments. 1

Specification, Operation and Maintenance Information

General

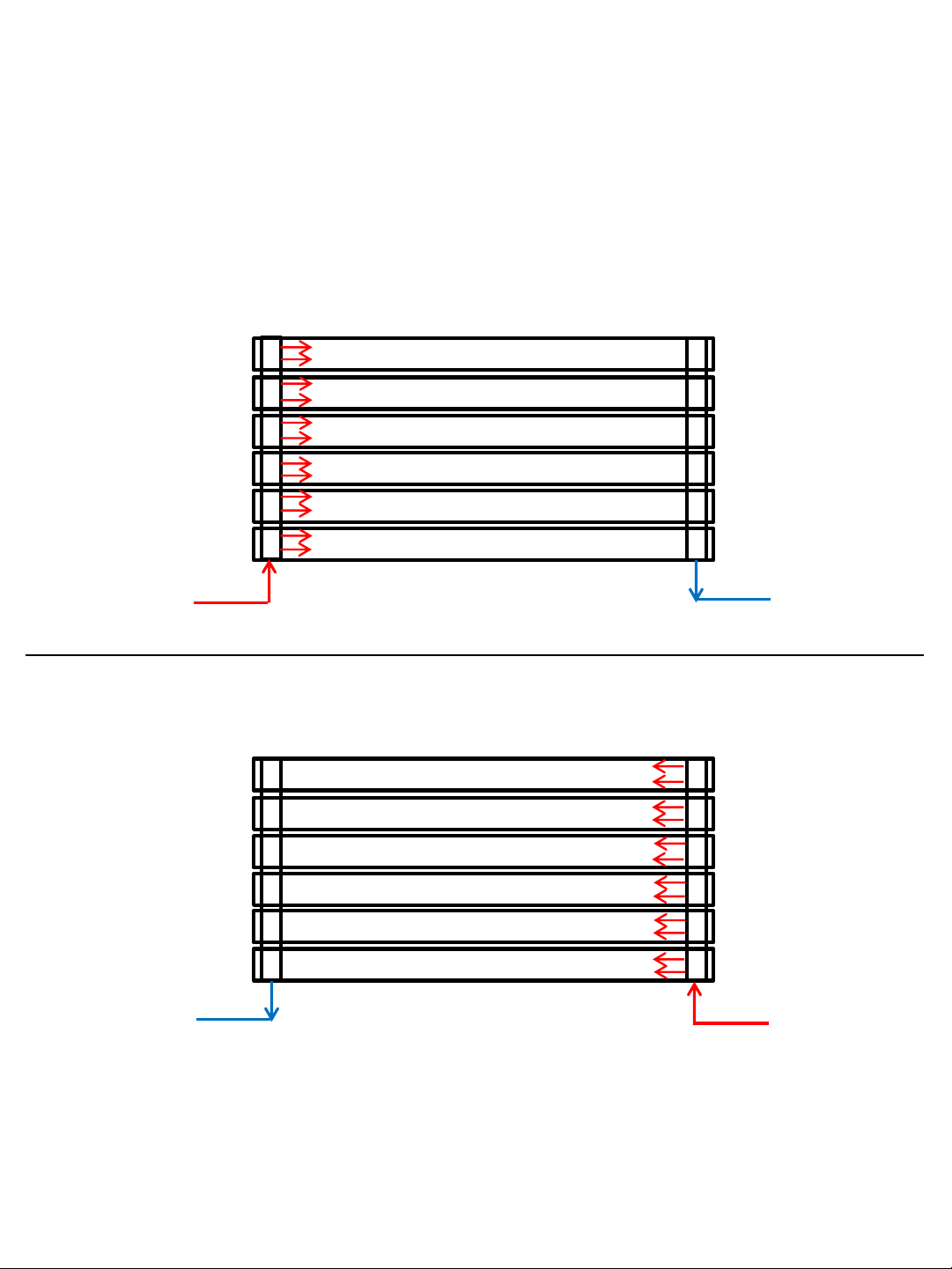

Horizontal