GRAPHTEC F-Mark User guide

Auto Sheet Feeder

Setup manual

User manual

Read this manual carefully before using the machine,

keep the manual in a handy place for future reference

index

1 Safety precautions

2 Main specifications

3 Dimensions

6 Accessory box

7 Cable connection

8 Overview and adjustings

9 iMark digital cutting software

10 F-Mark feeder position and push roller alignment

11 Cut the first test sheet

13 Print and cut alignment

15 Suction cups and insertion flap replacement.

16 Optical camera mounting

18 Troubleshooting

Safety Precautions

WARNING Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injuries.

Follow these guidelines to avoid the risk of fire, burns, injury,

electric shocks, rupture, overheating, abnormal odours or smoke.

Always use the recommended AC adapter (EA10682U-120) for the

ddCutter feeder to prevent any damage or failure.

The rated voltage is 110-240V AC 50-60Hz.

Do not touch the F-Mark device during a lightning storm.

Do not use the machine / AC adapter in places of high humidity

Do not overload the power cord.

Do not place heavy objects on, or damage the power cord or plug. Do

not forcibly bend or pull the power cord.

Make sure that the plug is fully inserted in the power outlet. Do not use

an outlet that is loose.

Do not allow the machine / AC adapter / power plug to get wet for

example, by handling them with wet hands or spilling beverages onto

them.

Do not disassemble or modify the F-Mark / AC adapter.

Disconnect the AC adapter and stop using the machine if you notice

abnormal odour, heat, discolouration, deformation or anything

unusual while using it.

CAUTION Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury.

Follow these guidelines to avoid the risk of, injury, electric shocks,

or damages to the ddCutter.

When placing the F-Mark device, allow enough table space, take in

consideration the vibrations generated during operations.

Ignoring to do this might cause the product or part of it to fall out of

position, resulting in possible body injury or malfunction of the

product.

Don not use or store the product is exposed to direct sunlight, water

or oil splashes, salty air or saltwater, dust or humidity, flamable gas.

Do not touch the paper sheets duting operation, the paper edge can

cut seriously your skin.

Do not approch with your face to the moving arm and moving paper

sheets.

Do not attempt to lubricate the mechanisms.

Do not apply force or object weights on the moving arm.

Lay the power adapter in a position so the green light is visible.

This will alert if the adapter should accidentally go off due to external

effects. If for any reason the green light goes off, disconnect theAC

power cord from the wall.

Be sure to grasp the plug, not the cable, when disconnecting the

power supply from an electric socket.

1

Main specifications

The F-Mark automatic feeder is part of the CE6000plus ASF

system.

It allows automatic operations for contour cutting on printed

adhesive sheets or cardboard.

The system is composed by an automatic feeder, a cutting

plotter, a dedicated software with optical detection features and

the exit tray.Amobile lever equipped with vacuum suction cups

lifts the sheets from the inbox tray and inserts them into the

plotter.

The F-Mark feeder is equipped with an internal vacuum pump,

which does not require external air connections.

The system is connected to a computer using a USB cable,

the dedicate software must be installed on a PC running

on Windows OS.

The safety precautions and specification here are referred to

the feeder unit only.

For safety precautions and specifications of the plotter, refer

to the Graphtec CE6000plus manual.

Media size

Width : 279

~ ~

350mm

( 300 350mm with CE6000-60)

Length : 210

A3, A4, SRA3, Extended A3 (A3, A4 not usable with CE6000-60 )

~500mm up to 700mm with optional extender

SRA3, A3Extended) ( A3

Sheet capacity About 200 sheets(limit depending on paper thickness)

Max height 35mm

Sheet weight350g/m2

Power source 100V~240V (Auto switching) 50/60Hz

Power consumption 60W

WeightFeeder 10kg Exit tray 4kx

Feeding system Internal vacuum pump

Feeding time 5 sec

Media separation Air blowers, variable air stream sseparation

Win7 / Win8.x / Win10

Feeder 590(L) x 400(W) x 220(H)mm

System including exit tray:

1220(L) x 680(W) x 270(H from tabletop )mm

Extender to 700mm sheets, stopper for small formats

Temperature: 10~35°Humidity 35~75%

Temperature: 0~40°Humidity 25~75%

Tabletop 800(L)x750(W)mm

Compatible OS

Dimensions

USB

Interface

Optional parts

Operating environment

Storage environment

Installation space

2

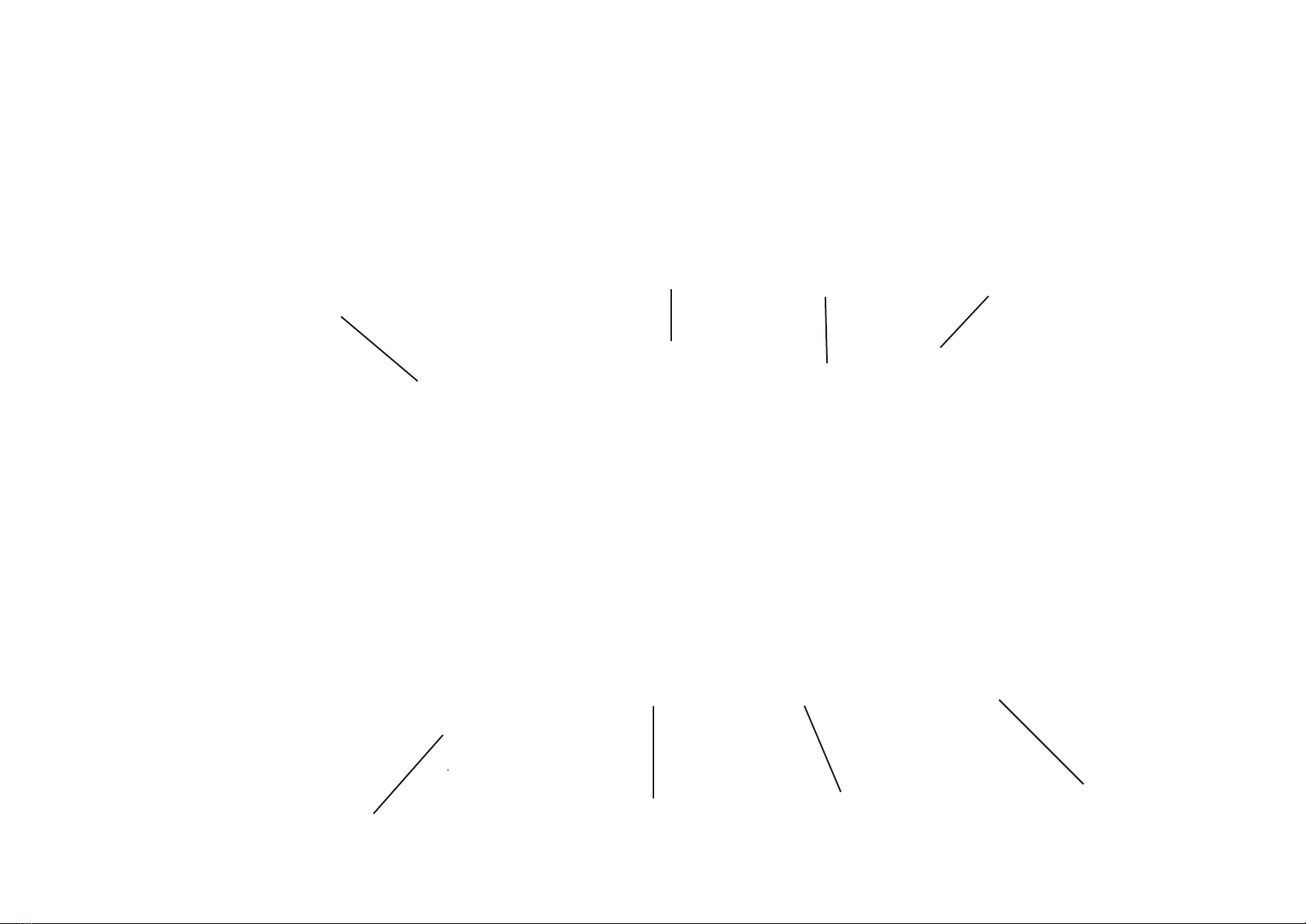

Dimensions

59 cm

22 cm

43 cm

120 cm

82 cm 42 cm

38 cm

Choose a location that allows an easy access

to the adjusting knobs.

3

38 cm

plotter width 70~90cm

The system can be configured with a plotter

different for size and maximum cutting area:

The tabletop length to accomodate the system

is 82cm, the width varies:

CE6000plus-40 with a plotter width of 70cm

CE6000plus-60 with a plotter width of 90cm

Allow 5cm of clearance on the right and left side

to accomodate the power cord an the USB cable.

The larger plotter model does not change the

maximum size of the sheet usable on the feeder.

The larger cutting area is usable when the plotter

is used separately by the feeder.

When you choose a location for the CE6000 ASF system note that

the exit tray extends for 35 cm and must be positioned in a

location free of tight passages to avoid hitting it when walking by.

4

Peel the adhesive tape on the back

of the exit tray. Press it firmly un the tabletop

The adhesive tape fix the exit tray for

a short time, it may drop if you do not

place the plotter on top.

Put the plotter on top of the exit tray

6 lines

To allow the paper to drop centrally on the

exit tray, place the plotter in order to align

the line 6 with the right edge of the exit

tray

5

Accessory box contents

Among the items on the accessory box the USB Hub is not normally necessary

it is used for troubleshooting in case of bad communicatrion betwern the computer and

the system. It may happen in case of overloaded usd port on th computer.

You have to connect the power cord to the power adapter and

the USB Hub with the miniUSB cable 1.8m long

Power adapter USB Hub power adapter

used only for

troubleshooting

USB cable 1.0m

from USB Hub to plotter

Mini USB cable 1.8m

from USB Hub to computer

USB Hub Spare suction cups

iMark software CD

Localized power cord for

power adapter

6

Cable connection

There are some USB cables and the power adapter that must be connected

before using the system.

Under the feeder there is an USB Hub fixed with a velcro tape for an easy

replacement.

The USB cable coming from inside the feeder is already connected, you

have to connect the cable from the optical camera and from the plotter.

For the CE6000-40 you can use the cable into the F-Mark accessory box.

for the CE6000-60 you have to use the USB cable from the plotter box.

The mini-USB cable goes to the computer, it is not necessary to install

drivers on the computer, you have just to wait until the system mathces the

different devices.

Depending on the computer you may have to wait few seconds up to some

minutes.

USB cable to the computer

USB cable to the plotter

USB cable to the camera

Internal USB

Bottom view

Power supply

7

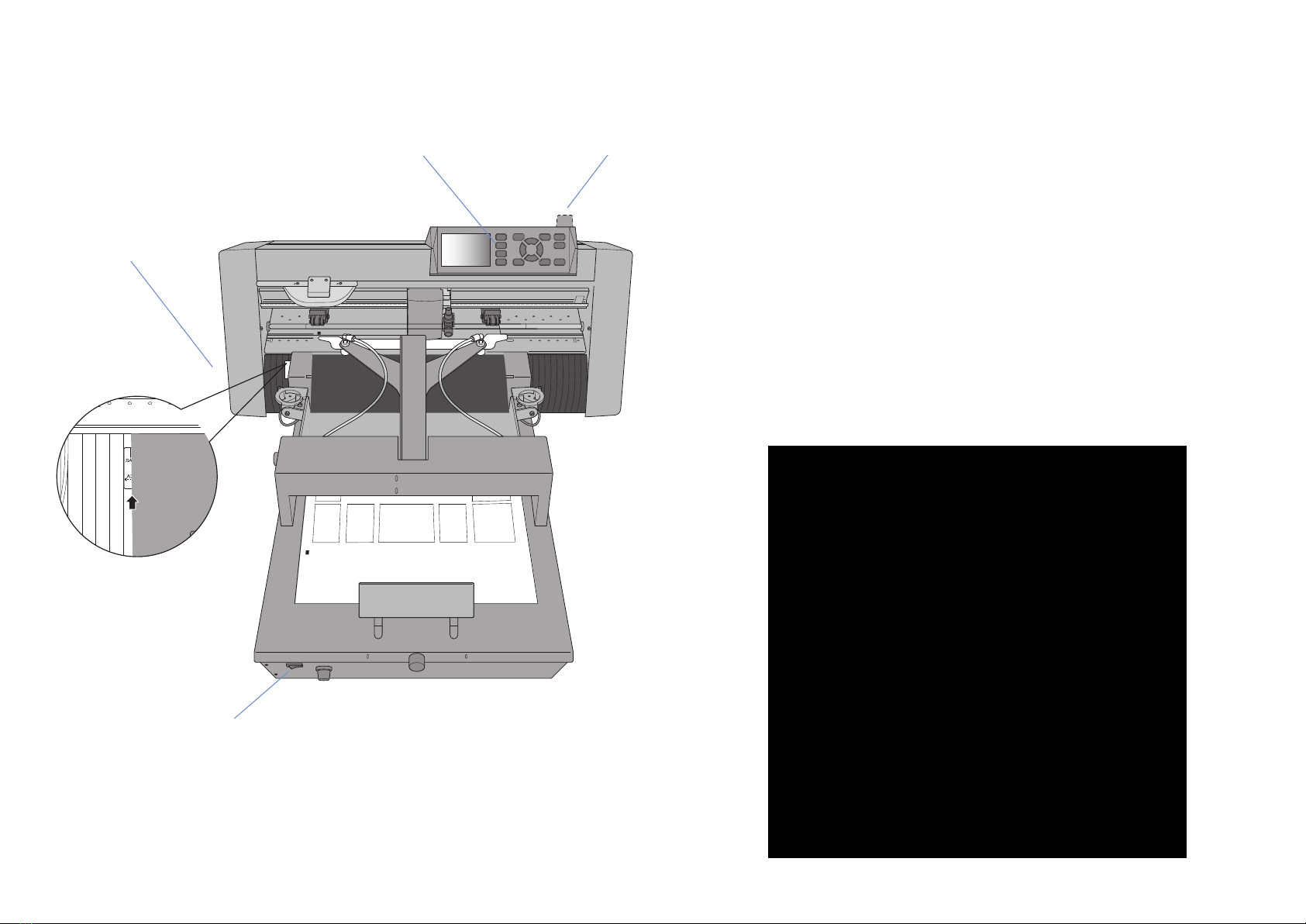

Insertion Flap

Suction Cup

Side paper guide

Blower

Blowers speed

regulation knob

Main switch Rear paper guide

regulation knob

Side paper guide

adjusting knob

Magnetic Mat

Overview and adjustings

On the F-Mark there some knobs that allow some adjustment

depending on the paper size and type.

The side paper guide knob adjusts the opening of the side

giudes accordingly to the media width.

Keep the side guide loose on the media borders.

The rear paper guide knob allows to press the media on the

front of the media tray.

Keep the rear guide tigth against the sheets,

The blowers knob paper

allows to adjust the air stream of the

blowers.

Aproper setting of the blowers speed helps the paper separation,

for adhesive media keep it at minimum or turn the blower off

forcing the knob counterclockwise.

For porous paper you may test different air stream levels, turns

the knob clockwise to increase the air stream. As a rule of the

thumb use a low air stream for curled prints and an higher level for

flat prints.

From the side view you can see Vacuum adjusting knob.

You can turn it clockwise to increase the vacuum force in case

the suction cup does not pick up the sheets.

Turn it counterclockwise when using thin paper and the suction

cups pick up more than one sheet.

To return to the default position turn the knob all clockwise and

then return back counterclockwise for two turns.

8

i-Mark Digital Cutting Software

This software has been designed to manage the automation of the cutting process.

There are specic functions to execute kiss cutting, die cutting and creasing simulation.

It allows users to import graphics les in AI and EPS format.

The graphics have to contain two reference marks.

The dedicated video camera connected to the software, detects the crop mark in a fraction of a

second and adapts the cut path to the inclination and distortion of the print.

The software runs with the operating systems Windows 7, 8, 10.

Most of old Windows Seven and XP computers can be used, but not all of them.

The system is connected to the computer through a USB port.

Installation of the Graphtec driver

DO NOT INSTALL THE GRAPHTEC DRIVER !

You only have to install the driver if you want to install the other software supplied with the

plotter.

In this case, before you connect the plotter to the computer, you have to install the plotter driver

contained in the CD.

Inside the CD le <<Ce6000 drivers>> there are two version of the driver, one for Windows 32bit

and one for Windows 64bit.

Install the version related to your computer, most of the new computers are 64bit, to verify you

must open the computer icon on the desktop.

Select on the menu <<System's propriety>> to visualize the system characteristics.

Installation of the i-Mark software

Execute the installation's program imark-setup contained in the installation CD.

The setup program requires various conrmations for the installation of the software.

On some computers you could be asked the system administrator password to execute the

installation, in case you do not have this information, contact the technician who administrates

the system.

During the installation, the i-Mark program icon is created on the desktop and a shortcut in

the Windows Start Menu.

At the end of the install process you can launch the i-Mark software.

9

When you launch the software you can see two preview

rectangular area on the top part ow the window.

Thel left one is a live preview of the camera view, the left

one is the last view when detecting the black mark.

The black mark has to be in a central position.

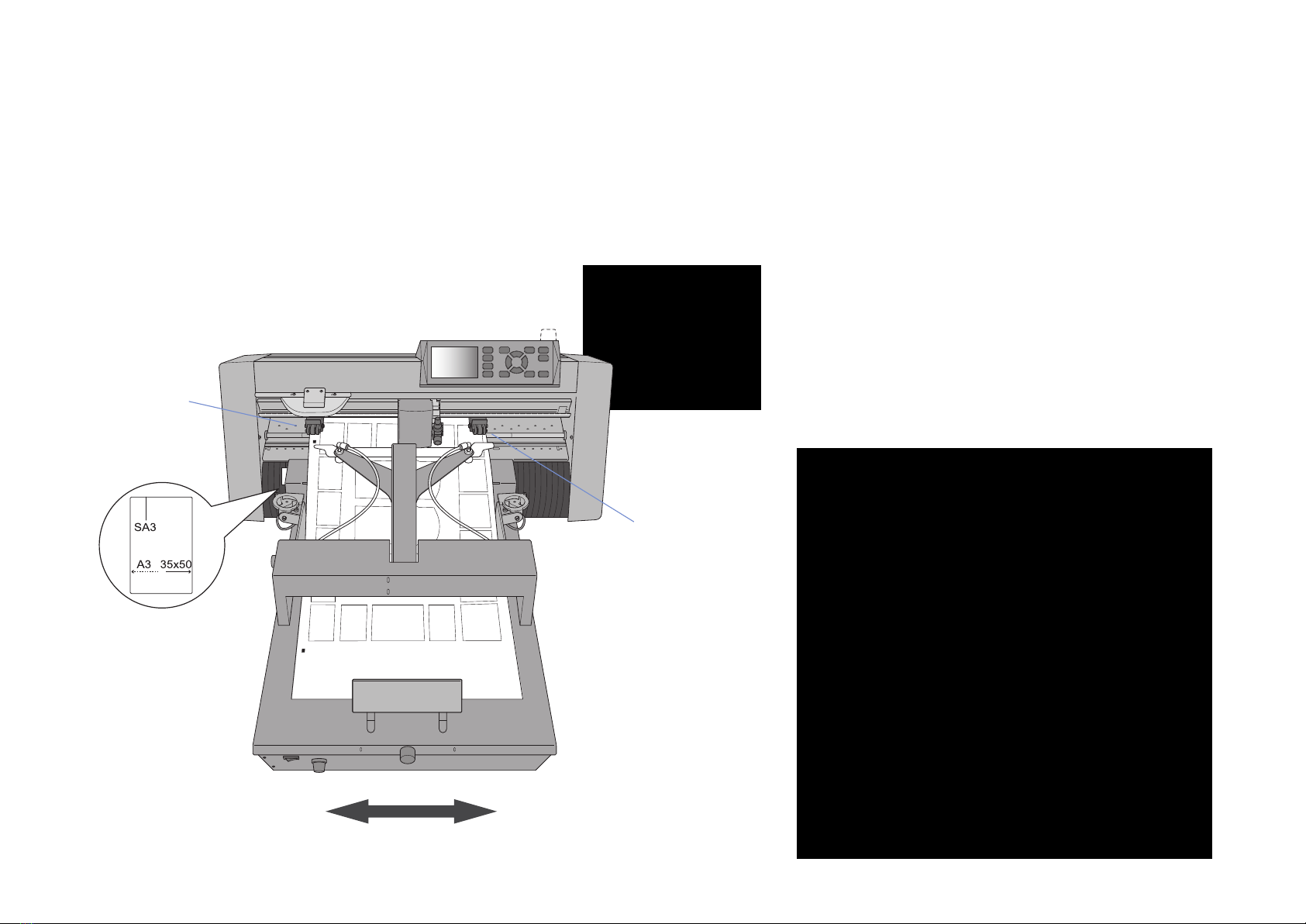

When you change the paper width the procedure is the following.

Adjust the paper guide using the side knob.

Lower the media lever.

Slide the feeder to aligne the left edge with paper size on the label.

Extract partially the sheet until it arrives under the push roller.

Push the left roller to the leftmost position.

Move the right push roller until some millimeter of paper are left on

his roght edge.

Check the position of the black mark on the camera preview.

You can slide the feeder left or right to reach a central position

of the black mark on the preview.

The position of the feeder changes depending on the paper width.

Left roller should

always be on the

lefmost position.

Lower the media lever

Align the right push roller

to the paper size.

F-Mark feeder position and push roller alignment

The feeder can slide left and right accordingly to the paper

width. On the plotter there is a label with the indication

where to align the left edge of the feeder for each paper size.

10

Load the test sheet to perform the first automated cut.

Turn on the plotter and the feeder.

Press the key 2 on the plotter panel.

If the plotter is set correctly, the cutting head moves left and right.

It has to stop near the left pinch roller.

On the software press the button ‘File Open’

Load the file label_test_contour_32x45.ai

If the system is correctly connected you see a green checkmark

on the bottom right of the window.

Insert the value 53 on the edit box ‘First Marker’

Press the button ‘Cut Test’ to perform the first cut.

The feeder load the sheet, each black mark stops under the camera

for detection and then start the cutting operation.

After the job have finished you can check the print-cut aligmnent.

You may have to follow the procedure on the next chapter for

a perfect alignemt.

Turn on the plotter

main switch on the

left side.

Turn on the plotter

main switch on the

left side.

Slide the feeder to the

SA3 line on the label.

When you turn on the F-Mark feeder, it performs an initialization cycle.

The arms moves up and down once until it stops in stand by position.

A red light appears on the switch button.

Rise the media leverPress key 2 on the panel

Cut the first test sheet.

11

Note that the blade holder has two different position, one for kiss cutting of adhesive sheets and the other for die cutting on cardboard.

The calibration process has to be operated ALWAYS with the blade on the adhesive cutting position.

The software arrange the correct position when using die cutting on the other position.

For further information regarding the alignment and for the software functions refer to the iMark software manual.

The blade holder can be inserted

in two different positions.

Adhesive cut position

Die cut position

12

Print and cut alignment

in this case the cut line is 0.5mm too low

set 5 on the Y value to move it higher.

The Y adjustment next to the preview allows you to set the

vertical position of the cut path.

By increasing the Y you move the cutting upwards.

By decreasing the Y you move the cutting downwards.

The X adjustment allows you to set up the horizontal position of

the cut path.

By increasing the X you move the cutting rightwards.

By decreasing the X you move the cutting leftwards.

The change of position is in tenths of a millimeter.

The adjustment is necessary the rst time you install the cutter.

When you press the 'Start' button the values are memorized

and the following adjustments start from a ‘zero’ value.

Small variation can be inserted also during the processing; every

variation will be eective from the next sheet.

The ‘Calibration’ button allow a cut-peel-measure procedure to nd the proper alignment between printed graphics and cut path.

You have to insert manually one of the black adhesive sheets provided.

Lower the media lever, insert manually the sheet, rise the lever and press the key #2 on the panel.

The sheet must be in a central position between the push rollers

You can align it with the edge of the feeder to keep it straight.

If the black adhesive sheets for the calibration procedure were not

available you can print the le caliblack.pdf available among the

sample les.

13

Press the ‘Calibration’ button

When you press ‘Cut Marker’

the plotter cuts a small square.

Press the ‘Read Marker’ button

to read the calibration values

When you press ‘Set’ you store

the values that are specic for

the camera installed on your

plotter.

Remove the small square adhesive to expose the white liner

When you have nished you can remove the calibration sheet

you have to rise the media lever, press the key #2 on the panel

then you can cut a sample sheet to check the alignment.

Press the ‘Calibration’ button

When you press ‘Cut Marker’

the plotter cuts a small square.

Press the ‘Read Marker’ button

to read the calibration values

When you press ‘Set’ you store

the values that are specic for

the camera installed on your

plotter.

Remove the small square adhesive to expose the white liner

When you have nished you can remove the calibration sheet

you have to rise the media lever, press the key #2 on the panel

then you can cut a sample sheet to check the alignment.

14

1

234

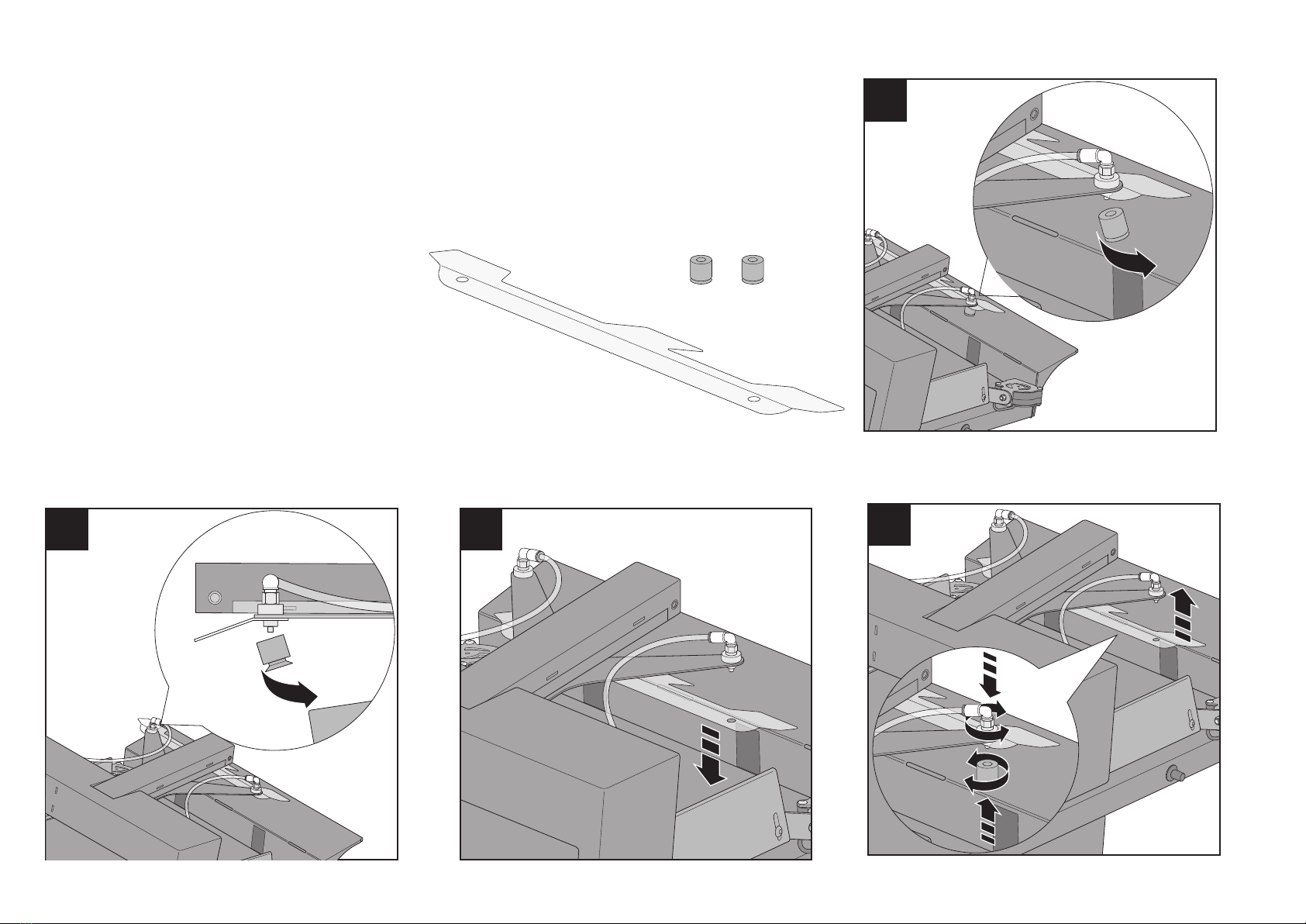

Suction cups and insertion flap replacement

There are two spare suction cups available into the accessory box.

You have to replace them when you notice some difficulties on picking

up the sheet. Upon a normal use of the feeder you have to replace

them once a year.

The insertion flap helps to keep the sheet flat during the unsertion.

You have to replace it when damaged.

1-2 Remove the left and right suction cup.

It get out easity if you pull it diagonally.

3 Replace the insertion flap if necessary

4 Insert the suction cups.

It is not so easey to insert the suction cup in place.

You have to hold the pneumatic terminal,

push firmly the custion cup

rotate bacn and forth the suction cup some times

until you can hear a click that means that it is in place.

You can moist it to help the insertion.

15

Remove the camera and accessories from the bag.

The camera is composed of two parts that you have to

separate before mounting.

1 Remove completely the right screw as in the picture.

2 Release the left screw until the lower bracket is

released, leave the left screw in place there is a plastic

ring tha hold it.

3 Separate the camera from the bracket.

4 place the bracket on the left side of the plotter as

on the picture, push it all at left as the arrow 1 an then

pull in the direction of arrow 2.

23

1

1

1

2

4

Optical camera mounting

16

5 Align the camera with the bracket, you can use the

hole where the screw have been removed fo the

alignment.

If you insert a white sheet on the plotter it may help to

see trough the hole.

Press firmly until the metal parts are in contact.

6 Fix the two screws tight.

7Add the adhesive clips on the left internal side of the

plotter, fix the camera cable on the clip.

Remove the plastic cap from the camera lens.

CLACK

5

6 7

17

Troubleshooting

1 - The feeder does not moves turning it on

The feeder does not execute the initialization cycle, the arm does not move when you turn on the switch.

Check if the green light on the switch is on.

2 - No video capture device message

When you launch the software you get the following error message:

It means that the software cannot detect the camera.

Check if the USB cable from the camera have been connected to the USB Hub

The driver for the camera is installed automatically, it may take few seconds

or some minutes it depends on the computer

NO

Check the connection of the power supply to the feeder.

Check that the green light on the power adapter is on.

Check that there is electricity on the main plug.

Check that the cord from the main plug to the power

adapter is well connected and the cord is not damaged.

IF

There is not light on the power adapter after the other tests:

Fault of the power adapter, ask for a replacement.

NO

Connect it on a free port on the HUB

YES

There is an internal fault on the feeder you have to contact

your dealer for service.

Turn the blowers knob clockwise to check if the blowers are

working so you supply this information when you call for

service.

YES

Check the USB connections, check that the cable that goes

from the computer to the HUB is connected on both sides.

Launch the software again to see if the messagge appears.

YES

Try to skip the HUB and connect the camera cable directly,

to the computer.

If the camera works the problem is on the Hub side

otherwise try on another computer.

If you continue to get the error there is an internal fault on the

camera you have to contact

your dealer for service.

18

3 - Feeder off or not connected

When you press ‘Cut Test’ or ‘Start’ from the software you get the following error message:

Turn on the feeder and repeat the command from the software.

The power switch in ON and you receive the same error message:

If the arm moves and executes the initialization cycle.

NO

If the arm does not move when turning the feeder on

Go to the troublshooting chapter 1 -

YES

Check the USB connections from the computer

to the USB Hub under the feeder.

Check the USB connections from the HUB to

the feeder, the camera and the plotter.

Move your hand under the camera, you should

see on the software preview.

IF you see your hand on the preview.

YES

Check again that the USB cable coming internally

from the feeder is connected to the HUB, if it is connected

the fault is internal to the feeder, call your dealer for service.

NO

There is a general USB connection issue, restart your

computer, try a different usb port on the computer,

check the if the USB connectors are damaged on the

cable or on the HUB.

To test the USB Hub functionality skip it connecting the

camera directly on the computer, if the camera works the

problem is on the Hub side otherwise try on another computer.

19

Other manuals for F-Mark

2

Table of contents

Popular Office Equipment manuals by other brands

Plus

Plus M-18S user manual

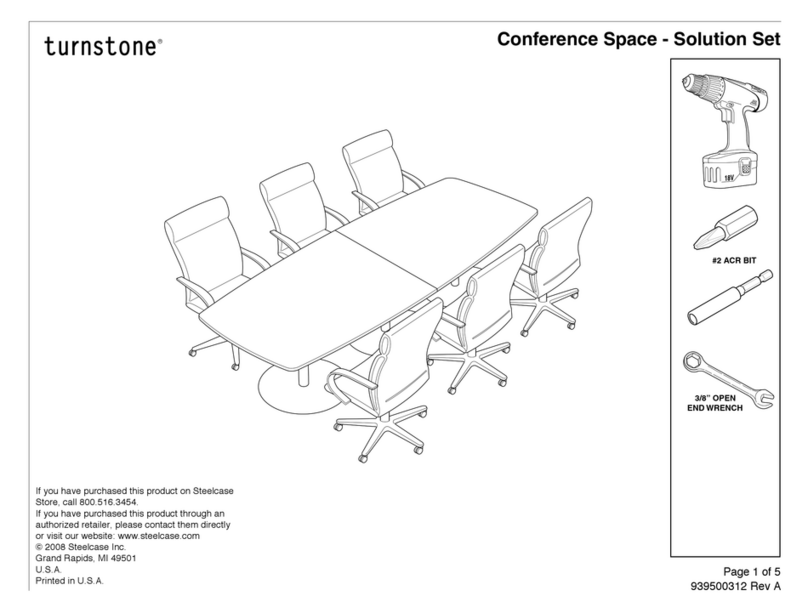

Steelcase

Steelcase Turnstone Conference Space Solution Set Assembly instructions

bejot

bejot Selva Hang SV HN 12 H5/6 Assembly manual

VISIONARY DESIGNS

VISIONARY DESIGNS Magellan Miracle instructions

Horshod

Horshod Ponyo user manual

Würth

Würth KV5700 Assembly, Mounting and Installation Instructions