Plockmatic BM 82 Installation manual

Provided By

http://www.MyBinding.com

http://www.MyBindingBlog.com

Plockmatic BM 82

Bookletmaker

Operation Manual

Stapler-Folder Model 82

Operator Manual

February 2003

Part No 76174

Stapler Folder Model 82 Operator Manual

T10136

Table of contents

1. Introduction

2. Getting to know the Model 82

2.1 Main components

2.2 The control panel

3. Operating and finishing modes

3.1 The operating modes

3.2 The finishing modes

3.3 Jam indications

4. Operatorinstructions

4.1 Connecting the Model 82 to a collator

4.2 Setting / Changing paper size

4.3 Adjusting the Stacker

4.4 Beginningtheproduction

5. Maintenance

5.1 Replacing the Staple cartridge

5.2 Removing Stapler head / clearing staple jam

5.3 Lubrication of Clinchers and Stapler Head

5.4 Cleaning of Fold rollers

5.5 GFI function test and resetting

6. Troubleshooting

7. Specifications

i

Stapler Folder Model 82 Operator Manual

T10136

Operational safety

This operator manual describes how to operate the Stapler-folder

Model 82 on-line together with collator Models 300/400, Model 100 or

as a stand alone unit.

1. Introduction

Always connect the equipment to a properly

grounded power source receptacle. In doubt,

have the receptacle checked by a qualified

electrician.

WARNING: Improper connection of the equip-

ment grounding conductor can result in electri-

cal shock.

Always follow all warnings marked on, or sup-

plied with, the equipment.

Always locate the equipment on a solid support

surface with adequate strength for the weight of

the machine.

Always exercise care in moving or relocating

the equipment.

Always keep magnets and all devices with

strong magnetic field away from the machine.

Never use a ground adapter plug to connect

the equipment to a power source receptacle

that lacks a ground connection terminal.

Never attempt any maintenance function that is

not specifically described in this documentation.

Never remove the covers or guards that are

fastened with screws.

Never install the unit near a radiator or any

other heat source.

Never override or “cheat” electrical or

mechanical interlock devices.

Never operate the equipment if you notice

unusual noises or odors. Disconnect the power

cord from the power source receptacle and call

your customer service engineer to correct the

problem.

Attention to the following notes ensures the continued safety operation of your equipment.

1-1

Stapler Folder Model 82 Operator Manual

T10136

10

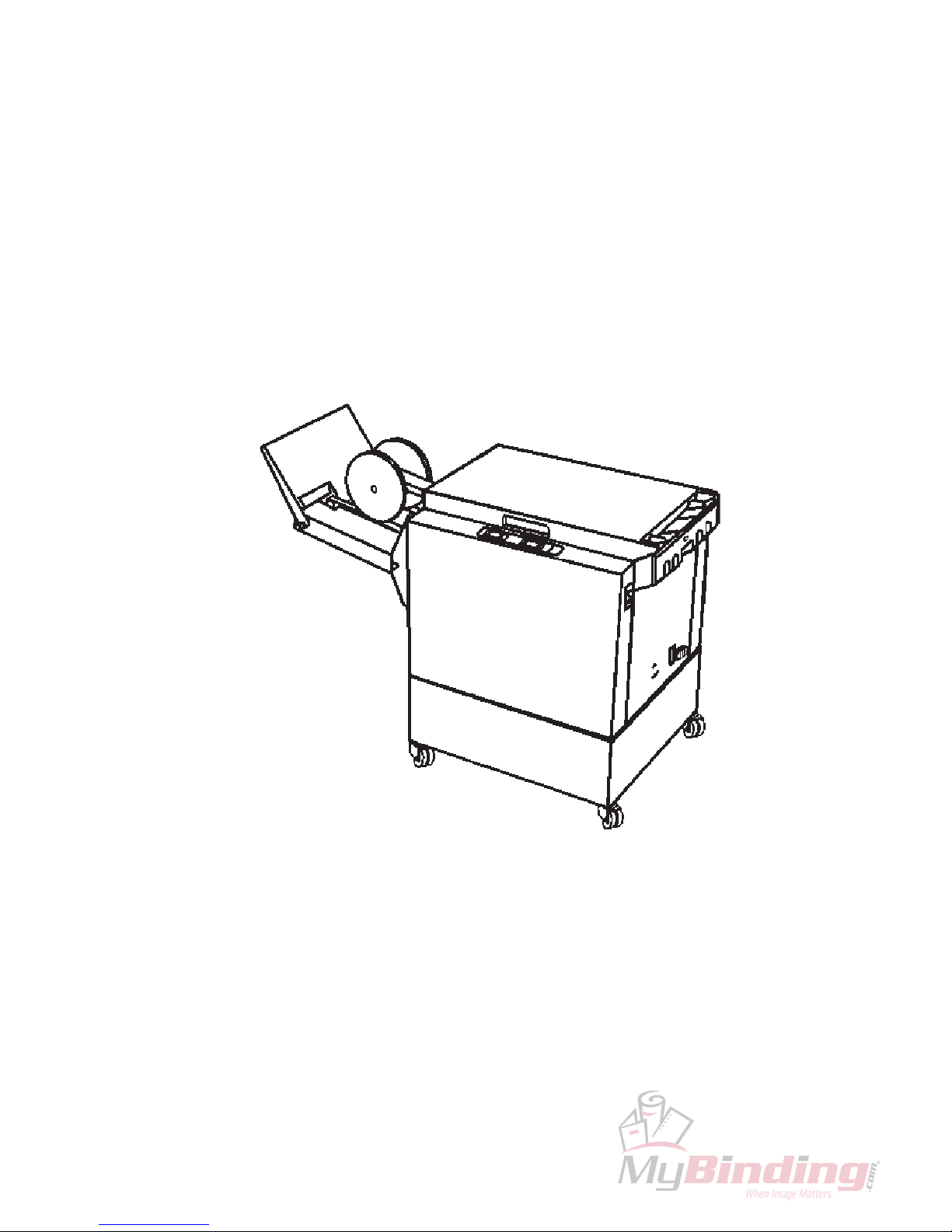

2. Getting to know the Model 82

Takea fewminutes tobecome familiar withthe maincomponents

ofthe Model82.

1. Output wheels 7. Power switch

2. Belt stacker 8. Ground fault interruptor (GFI )

3. Control panel 9. Power cord receptacle incl. fuses

4. Top cover 10. Connection cable outlet

5. Docking assembly 11. Base

6. Back jogger adjustment screw

2.1 Main components

2

3

4

5

7

8

9

1

11

2-1

6

Stapler Folder Model 82 Operator Manual

T10136

1

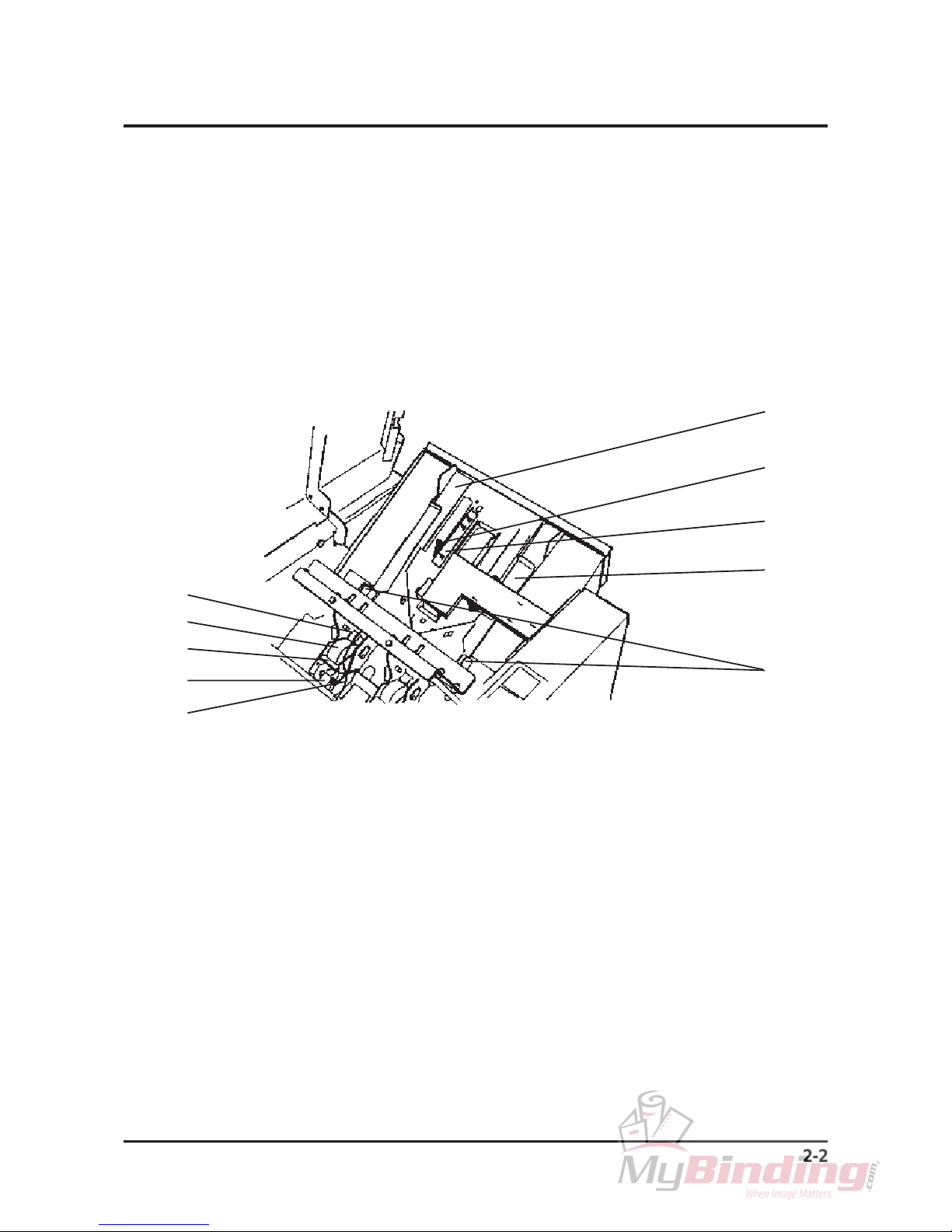

2.1 Main components cont.

1. Stapler head 6. Rear Side guide

2. Staple cartridge 7. Back jogger

3. Cartridge locking lever 8. Scale, length adjustment

4. Stapler release latch 9. Front Side guide

5. Staple detection lead 10. Release handle, Side guide

2

3

4

5

6

7

8

9

10

Whensetting upthe Model 82 or performingmaintenance itis

sometimesrequiredto moveinternal components ofthe machine.

Take afew minutes tobecome familiarwith these components.

2-2

Stapler Folder Model 82 Operator Manual

T10136

1

2.2 Control panel

1. Auto mode indicator 9. Stacker full indicator

2. Manual mode indicator 10. Staple(s) missing indicator

3. Staple and fold mode indicator 11. Manual / Auto mode button

4. Fold mode indicator 12. Program select button

5. Edge stapling mode indicator 13. Run / Adjustment mode button

6. Run mode indicator 14. Length adjustment button, decrease

7. Adjustment mode indicator 15. Length adjustment button, increase

8. Paper jam indicator

23 645 7 8910

11 12 13 14 15

2-3

Stapler Folder Model 82 Operator Manual

T10136

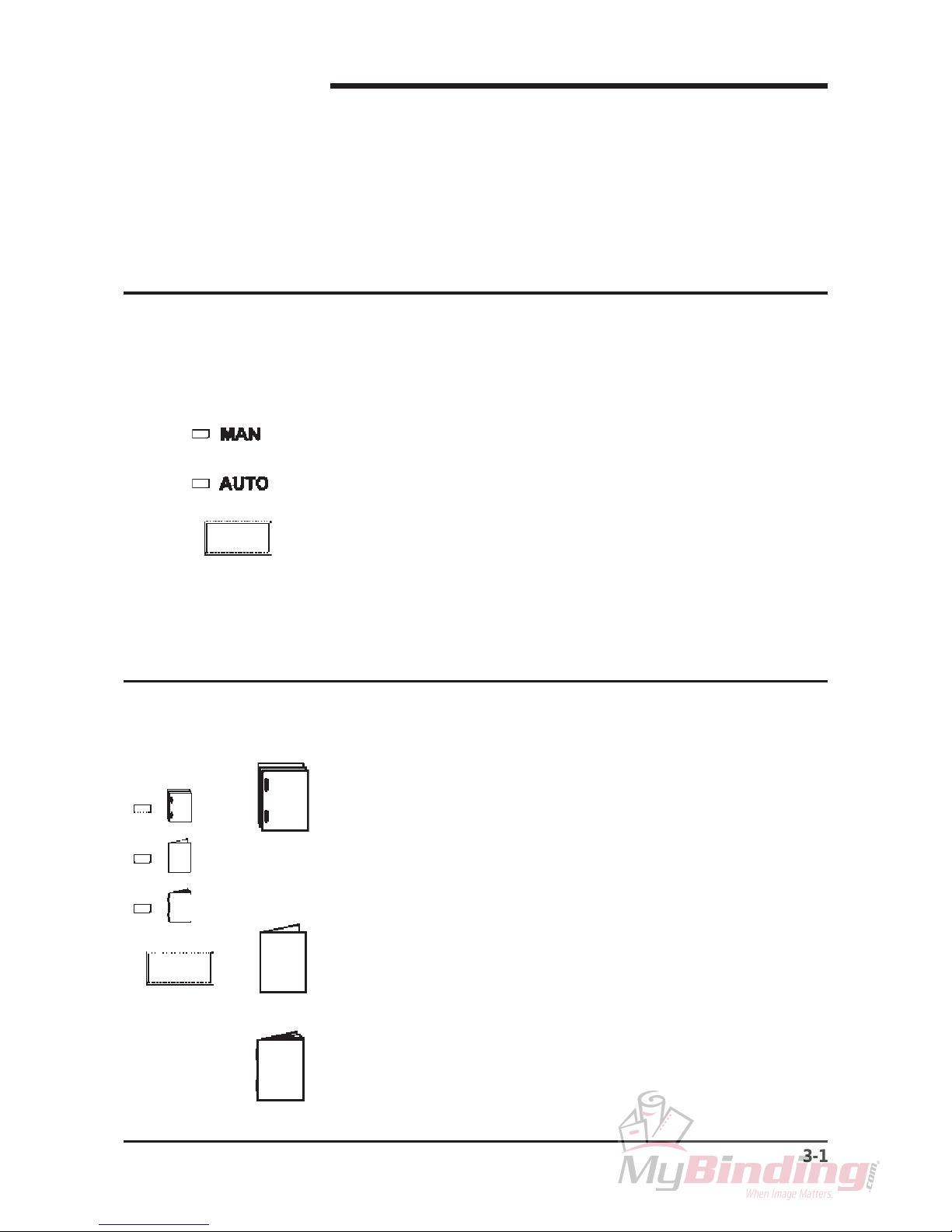

3. Operating and finishing modes

TheModel 82 canbe operated inseveral combinations ofmodes.

Thesemodes aretwo operatingmodes and threefinishing

modes.In this sectionwe will explainthe different modesand how

theyareselected.

3.1 The operating modes

3.2 The finishing modes

3-1

Thethreefinishing modesare:

1. Edge stapling

Whenselecting thismode by pressingthe Programselect

buttontheset willexitat the loweroutputarea.Adeliverytrayfor

edge stapled sets is available, part no. 750004.

IfaTrimmeris installedto yourModel 82, remove the scrappaper

binto allow theedge stapledsetsto enterthe delivery traywhich

isintegrated inthe baseof theTrimmer.

2. Fold only

Whenselecting this modeby pressingtheProgram selectbutton,

thestapler actionis switched off and thefolded setwill exitat the

upperoutputarea ontothebelt stacker.

3. Saddle stapling and fold

Whenselecting this modeby pressingtheProgram selectbutton,

thestapled andfoldedsets willexit attheupper outputarea onto

thebeltstacker.

Thetwo operatingmodes are:

1. Manual mode

SelectManual mode ifoperating the Model82 as astand alone

unit,forhandfeeding.

TheManual modeis selectedwhen theMAN LEDis lit.

Pressthe Manual /Automodebutton tochangeoperating mode.

2. Automatic mode

SelectAutomaticmode if operating theModel 82together witha

collatorasan on-line system.

TheAutomaticmode isselected whentheAUTOLEDis lit.

Pressthe Manual /Automodebutton tochangeoperating mode.

Note: If in manual mode when the on-line connected collator starts, the

mode will automatically switch from Manual to Automatic mode, to

preventinterruptions.

Stapler Folder Model 82 Operator Manual

T10136

3.3 Jam indications

1. Staple(s) missing indicator

TheStaple(s) missingindicator isilluminated whena setis

missingone or twostaples. TheModel82 willautomatically

stopthe on-linesystem when thisindicator LEDis lit.

Uponindication afterloading anew staplecartridge, open

andclose the Topcover.TheModel82 willnow cycle and

advancestaples onthe sameset fora maximumof 5

staplingcycles or untilstaples are resumed.Replacing the

staple cartridge is described in section 5.

2. Stacker full indicator

TheStackerfullindicator islit when thebelt stackerorthe

deliverytray is full.Remove the finishedsets.Assoonasthe

stackerfull sensoris clear theindication willgo off. The

Model82will automatically stoptheon-line system whenthis

indicatorLED is lit.All setsalready fedfrom the Collatorwill

beprocessed until fullstoppage.

3. Paper jam indicator

ThePaper jamindicator is illuminatedwhen anoperation in

theModel 82is not done within thepreset time.Open the

topcover andremovethe jammedsets reachable,closethe

topcover and theModel 82willautomatically purge

remainingjammed sets. Model82 willautomaticallystop the

on-linesystem whenthisindicator LEDis lit.

3-2

Table of contents