GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 08/2011

- 2 -

Please be sure to read through the Safety Notes in the Appendix to these operating instruc-

tions. If you ever dispose of the model, it is important to pass on the complete building instruc-

tions to the new owner.

Introduction

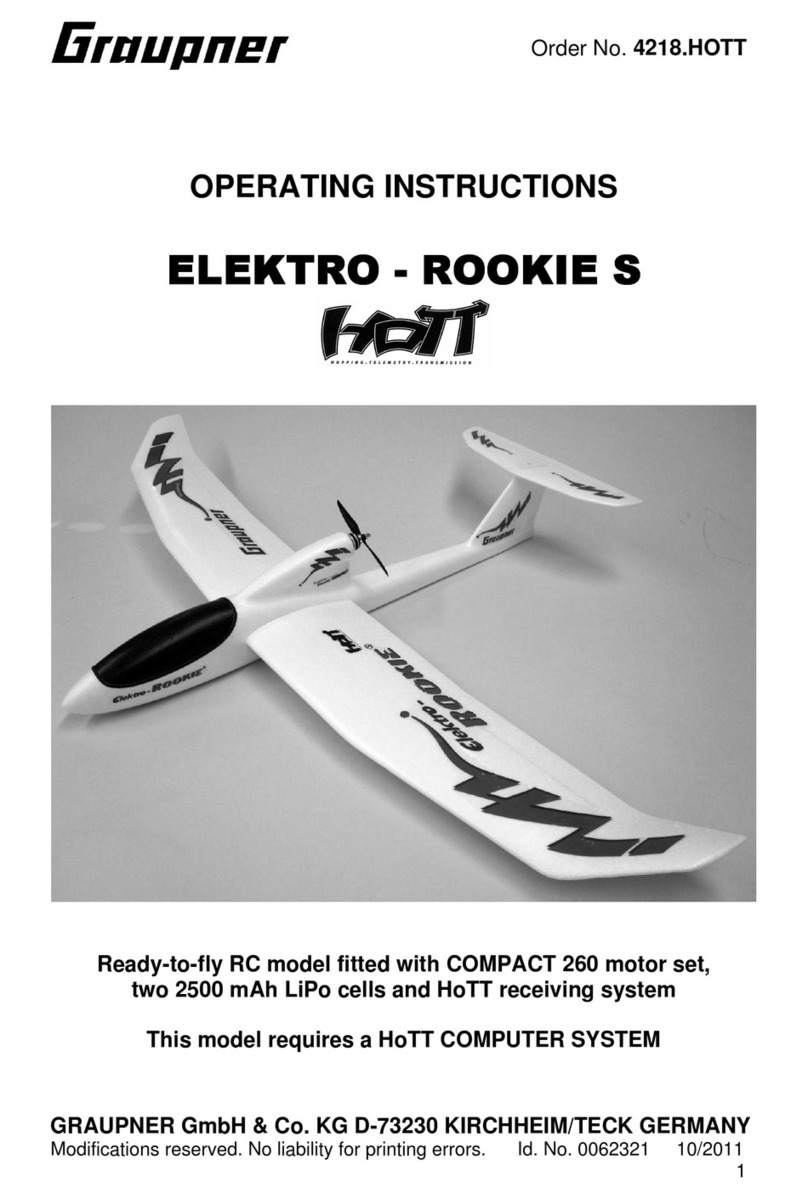

The STARLET is an attractive electric-powered RC model aircraft which is easy to

transport thanks to its compact dimensions. However, do not let its small size deceive

you: the model requires some prior modelling experience if you are to assemble and

operate it successfully. The aeroplane is highly pre-fabricated, but the work which

you have to carry out is important, and must be done carefully. The model will only be

strong and fly well if you complete your tasks competently. The all-up weight must

not exceed 550 g.

RC system accessories (not included)

The following items are required to complete and fly the model.

GRAUPNER MX-12 HoTT 2.4 GHz COMPUTER SYSTEM Order No.33112

Transmitter charge lead Order No.3022

COMPACT 260Z brushless motor Order No.7731

Spinner, 28 mm Ø Order No.7731.1

CAM SLIM PROP, 17 x 7.5 cm Order No.1372.17.7,5

BRUSHLESS CONTROL 8 speed controller Order No.7231

LiPo 3/650 flight battery, 11.1 V / 0.65 Ah Order No.7609.3

Charge lead with BEC connector Order No.3037

ULTRAMAT 16 S battery charger Order No.6468

DES 427 BB servo (four required) Order No. 7910

Servo extension lead, 100 mm (two required) Order No.3935.11

Servo extension lead, 180 mm (two required) Order No.3935.18

Essential tools and adhesives (not included)

Balsa knife Order No.980

Cyano-acrylate (“cyano”) Order No.5821

Cyano activator Order No.953.150

UHU ALLESKLEBER Kraft Order No.1096

You will also need the following items: cross-point screwdriver, 8 mm A/F open-

ended spanner, flat-nose pliers, side-cutters, 1.0, 1.6, 2.2 and 3.0 mm Ø drill bits, 1.5,

2.0 and 2.5 mm A/F allen keys, soldering iron and solder, heat-gun, glasspaper, set-

square, spirit felt-tip pen, adhesive tape, paper towel, rubber gloves, protective gog-

gles.

Building instructions

Please read right through these building instructions before you start construction, so

that you have a clear understanding of the sequence of assembly. Before you start

on a particular stage, make sure you have all the requisite components, tools and

adhesives to hand. When assembling the model always work on a clean, smooth, flat

surface, or on a workbench with a foam overlay. Unless stated otherwise, use cyano

adhesive with activator for all joints on this model. The best method is to apply cyano

to one surface, then spray the opposite face with activator. Ensure that excess glue

does not get onto your hands or the model’s finished surfaces. Wipe off excess glue

immediately using a piece of paper towel.