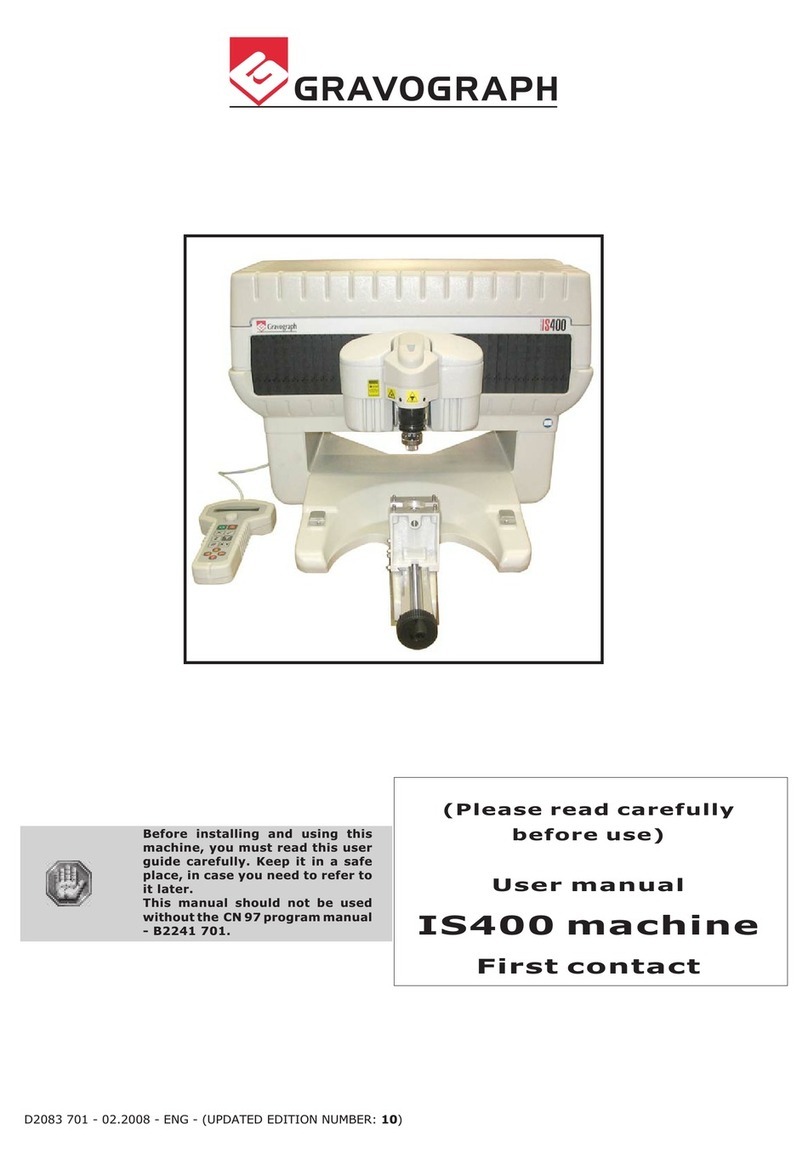

First contact

L-SOLUTION 700 / 800 / 900 m chines . 3

ummary

Regulatory information ....................................................................... 5

Compli nce st nd rds ...................................................................................................................... 5

Electric l security ............................................................................................................................ 5

Overview ............................................................................................ 6

Introduction ................................................................................................................................... 6

Contr -indic tions ........................................................................................................................... 6

Unp cking st ges ............................................................................................................................ 8

Unp cking - P ck ge contents ........................................................................................................... 9

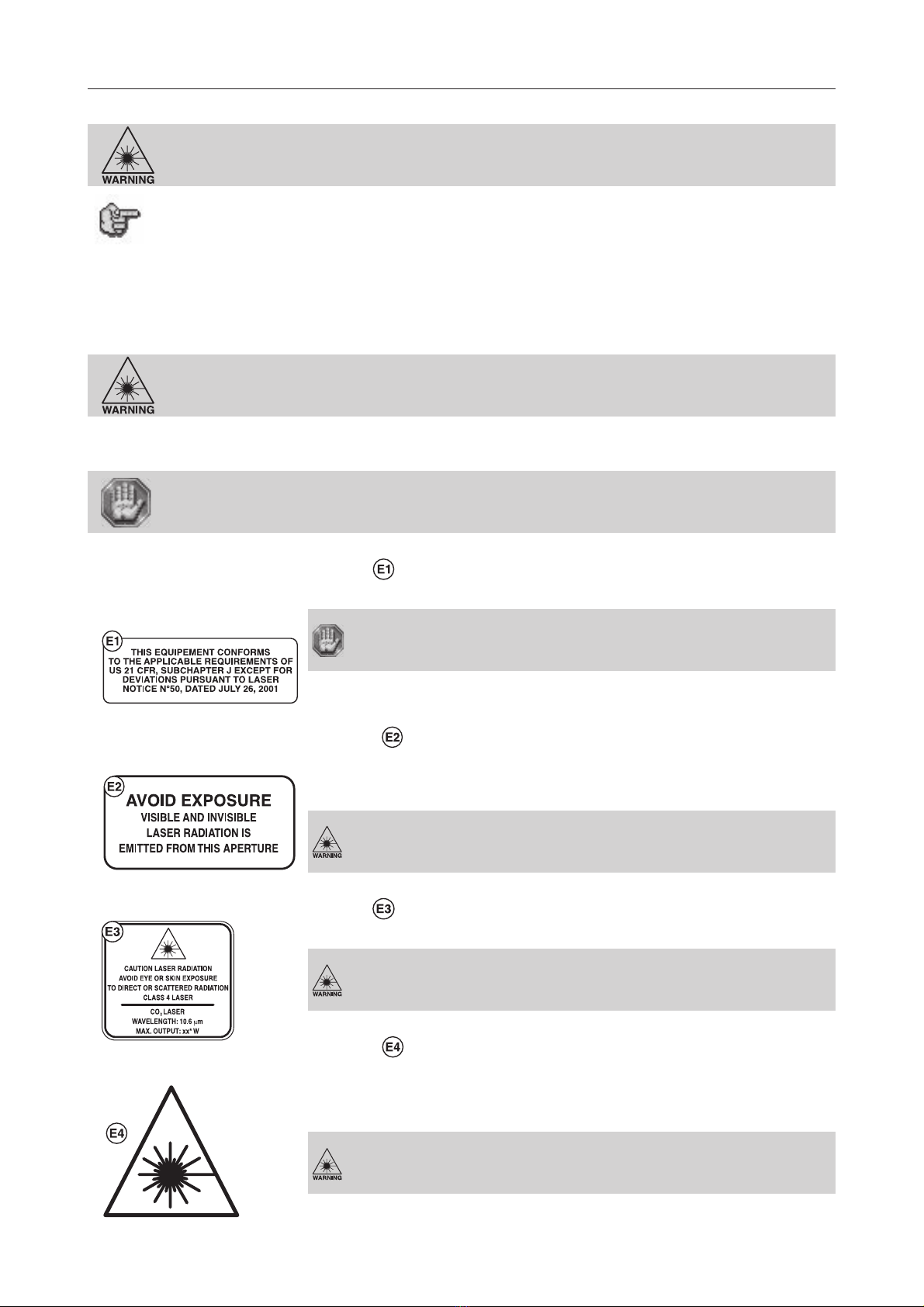

LASER s fety ................................................................................................................................ 10

Description ....................................................................................... 13

Front view of the m chine .............................................................................................................. 13

Re r view of the m chine ............................................................................................................... 14

Installation ....................................................................................... 15

Physic l inst ll tion recommend tions .............................................................................................. 15

Exh ust system inst ll tion recommend tions ................................................................................... 17

Air- ssist requirements (compressor option l) ...................................................................................17

Computer requirements ................................................................................................................. 18

Softw re suggestions ..................................................................................................................... 18

Font requirements ......................................................................................................................... 18

Electric inst ll tion recommend tions ............................................................................................... 19

Electric l connections of the m chine ............................................................................................... 21

Powering the m chine on ............................................................................................................... 22

Problems ...................................................................................................................................... 22

Powering the m chine off ............................................................................................................... 22

Mech nic l j mming ...................................................................................................................... 22

Powering on g in ......................................................................................................................... 22

etting up transmission between the L- OLUTION (700 / 800 / 900)

machine and a PC type computer ...................................................... 23

Connection c bles ......................................................................................................................... 23

Connecting L-SOLUTION to your PC using the USB port ...................................................................... 24

Connecting L-SOLUTION to your PC using the p r llel port .................................................................. 25

Connecting L-SOLUTION to your PC using the seri l port (only with the old m chines) ............................ 26

M chine setup (l ngu ge)............................................................................................................... 27

The printer driver of the LA ER machine........................................... 29

How the computer controls the LASER m chine ................................................................................. 29

Inst lling the Windows® (Windows 2000®, XP® or 98®) driver ......................................................... 30

Driver controls .............................................................................................................................. 43

Graphics software ............................................................................. 64

Softw re setup .............................................................................................................................. 64

Speed optimiz tion ........................................................................................................................ 65

Bitm pped / sc nned im ges .......................................................................................................... 65