Summary

Information about regulations .............................................................5

Conformity Standards.......................................................................................................................5

Electrical security.............................................................................................................................5

Presentation.........................................................................................6

Contra-indications ...........................................................................................................................6

Stages of unpacking........................................................................................................................8

Unpacking - Contents of package.......................................................................................................9

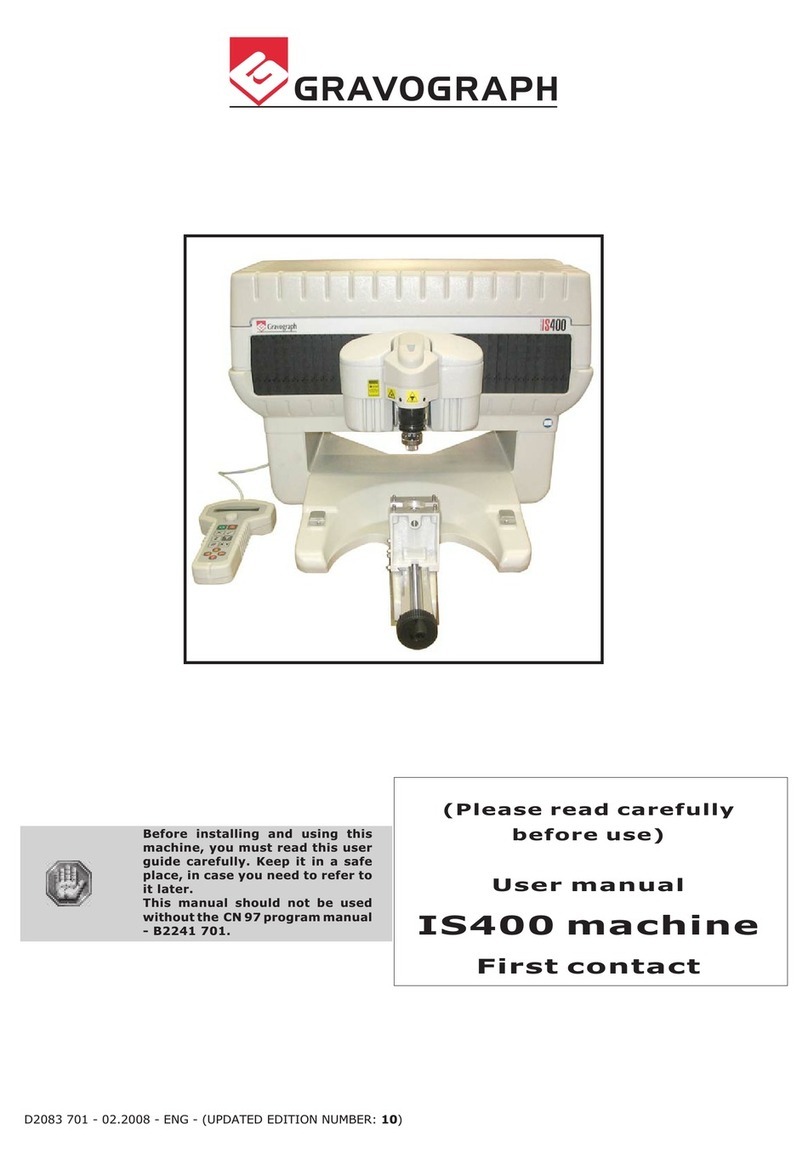

Description.........................................................................................11

Front view of the machine............................................................................................................... 11

Engraving table........................................................................................................................................ 11

Tool holder - standard motor - 90W ............................................................................................................ 12

Tool holder - optional motor - 200W............................................................................................................ 13

Control panel........................................................................................................................................... 14

Clamping table......................................................................................................................................... 15

Vice (Option)........................................................................................................................................... 15

Rear view of the machine................................................................................................................ 16

Engraving machine connections.................................................................................................................. 16

IS electronics box connections ................................................................................................................... 16

200W motorization connections (Option)..................................................................................................... 17

Installation ........................................................................................18

Physical installation advice.............................................................................................................. 18

Electric installation advice.............................................................................................................. 19

Electrical connections of the machine ............................................................................................... 20

Machine with a standard spindle - 90W motor.............................................................................................. 20

Machine with the optional spindle - 200W motor........................................................................................... 21

Machine with the High Frequency spindle 150W - Option ............................................................................... 22

Connecting the IS900 IQ+machine to a PC...................................................................................... 24

Switching the machine on............................................................................................................... 26

Problems...................................................................................................................................... 26

Switching the machine off............................................................................................................... 26

Mechanical block............................................................................................................................ 26

Switching on again......................................................................................................................... 26

Conguration de la machine (langue) ............................................................................................... 27

Make the IS900 IQ+machine ready to engrave with GravoStyle 5....................................................... 28

Engraving...........................................................................................29

Positioning the plate on the clamping table........................................................................................ 30

Positioning the plate onto the vice (in option).................................................................................... 32

Point and Shoot............................................................................................................................. 33

Transfer........................................................................................................................................ 34

Activation of the RDF function ......................................................................................................... 34

Adjusting the spindle...................................................................................................................... 35

Adjusting the spindle pressure......................................................................................................... 35

Putting the cutter into the spindle .................................................................................................... 36

Adjusting the rotation speed of the spindle........................................................................................ 38

Launching the engraving................................................................................................................. 39