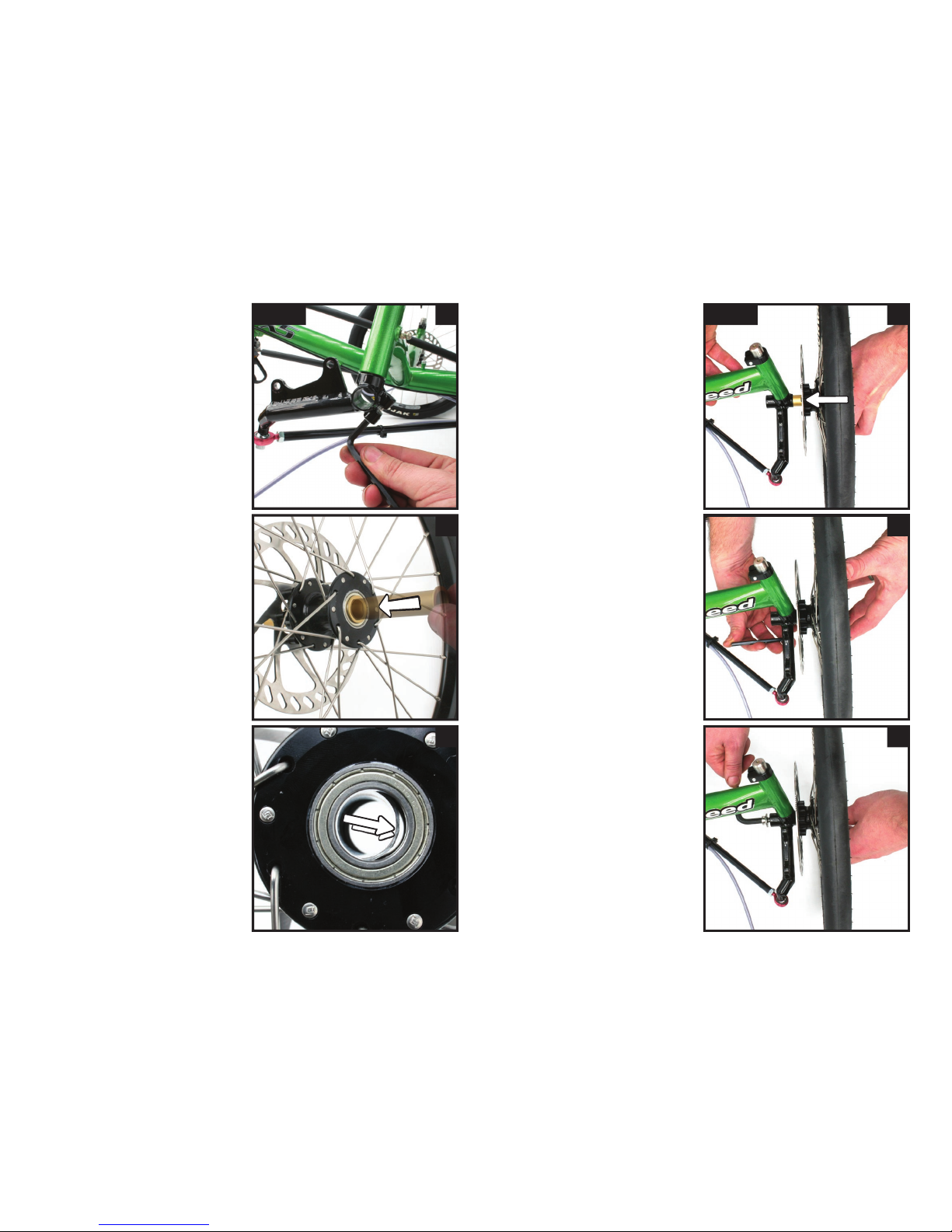

Disc wheels will then need

the calipers installed.

Start with the forward most

screw (fig 6a) and fit one

washers under the screw

head and the other washer

(and any spacers) on the

caliper side of the mount (fig

6b).

Leave this screw loose so it

is easier to put the second

screw in with its washers (fig

6c), and tighten up both of

the bolts.

Your pads are self adjusting,

so should center themselves

either side of the disc after

use.

However, if when you put

the caliper on, you can see

that the slot for the pads is

obviously out of alignment

you may need to see a

dealer for new spacers.

screw

washer

mount

spacers

(if needed)

washer

caliper

fig 6 a

b

c

fitting your

disc brake

calipers

As the brakes are self-adjusting for pad wear, squeezing the

brake levers with no disc between the pads will result in the pads

coming together and the disc

rotor will no longer fit. A flat

blade screwdriver will then be

required to separate them for

installation. If the pads are

quite worn, you chance push-

ing one of the pistons from

the caliper! We suggest you

keep the transporting spacers

that came with your trike and

use them between the pads

when transporting if you plan

to remove the wheels.

Note: Care needs to be taken with hydaulic disc brakes in

general in regards to transporting with the wheels/calipers

removed. Cable discs do not need this.

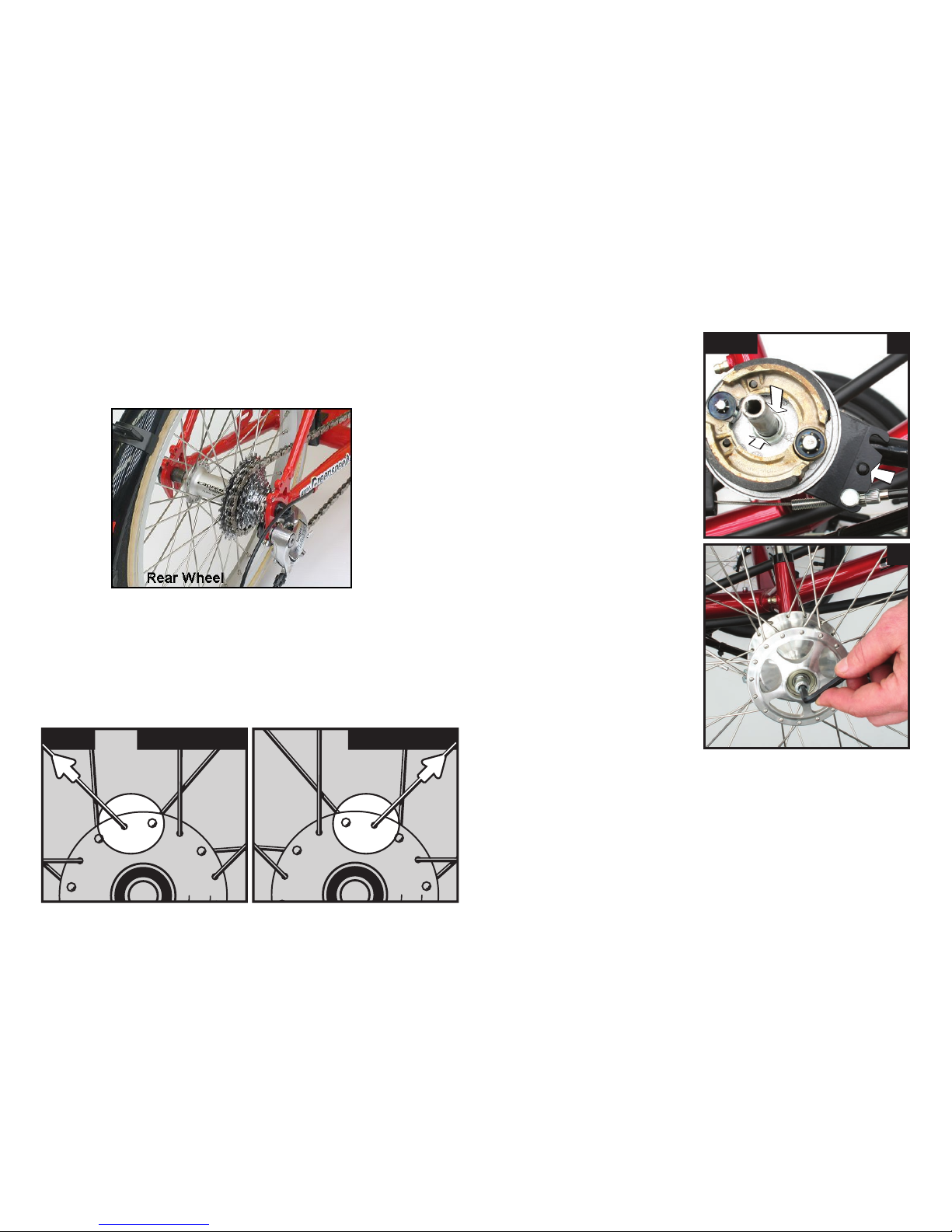

When removing and refitting your hollow axle wheels at a later

point, the caliper can stay in place. In this scenario, to take off

the wheel, simply take out your axle pre-load bolt and loosen the

clamp screw and slide the axle out first, then drop your wheel,

and therefore disc brake rotor, down out of the caliper. To put it

back on, make sure the clamp is undone, offer the wheel up and

insert the disc rotor into the caliper taking care to not dislodge

the brake pads. Insert the axle from the outside of the hub and

straight through into the kingpin. Insert and tighten the bolts as

instructed above in ‘fitting your wheels - disc brake with hollow

axles’.

removing hollow axle wheels

fig 7

7