1

October 5, 2020

New Valves for Replacement of Existing Equipment

New valves are tested, sealed and packaged at the time of manufacture. A new valve can be applied provided it is still in its original

packaging and tested within 6 months of the installation date. A valve with a test date older than 6 months must have the O-rings

replaced and retested.

Safety relief valves are spring loaded devices that can store a significant amount of energy. Assembly and disassembly

must be performed by trained, qualified personnel.

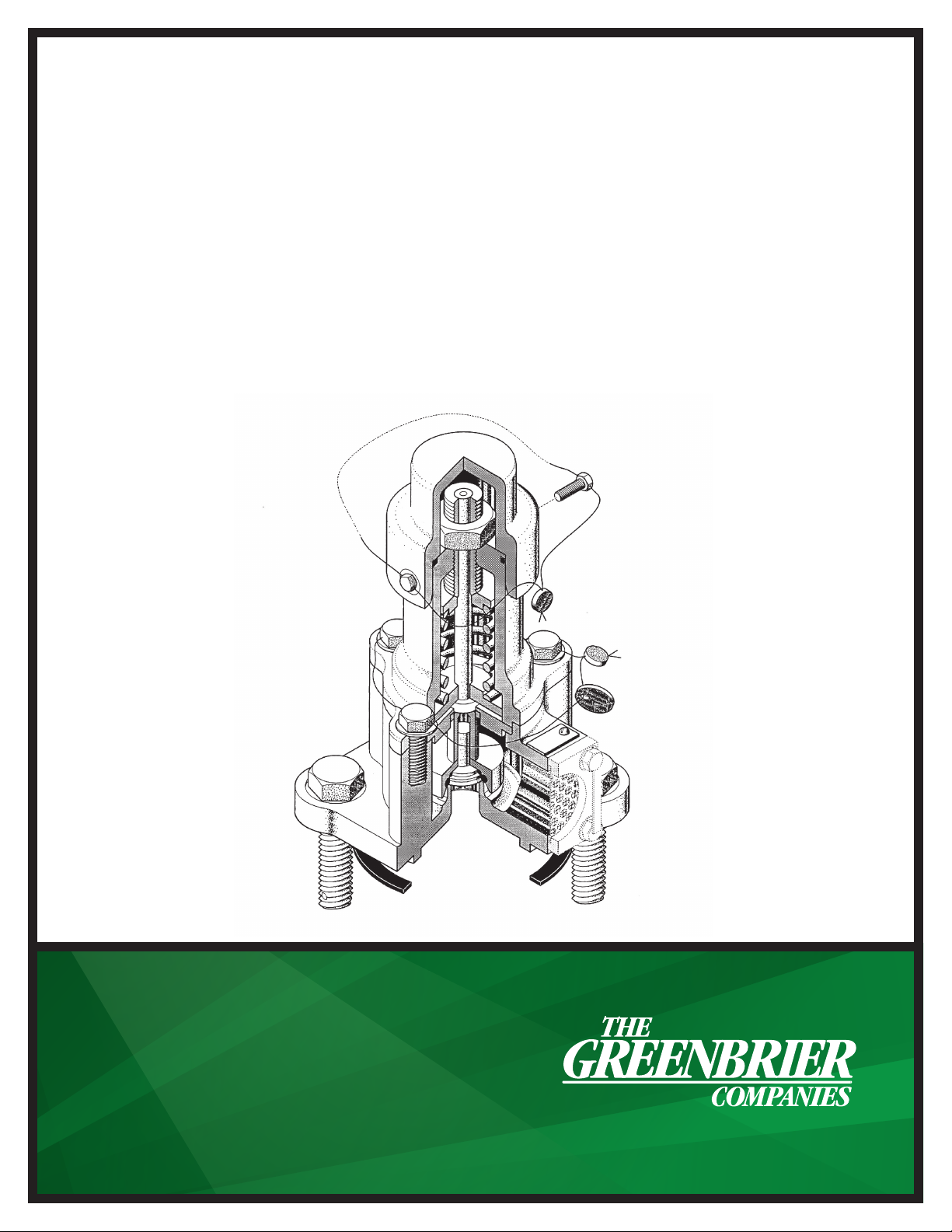

Disassembly Procedure

1. Remove the 2 seal wires, item #16.

2. Remove the two bolts securing the valve cover, item

#4, to the upper housing, item #2 then remove the

valve cover and the O-ring, item #21, taking care not to

mar the O-ring groove.

3. Measure and record the distance from the end of the

adjustment screw to the top of the jam nut, item #9.

This dimension will be used at reassembly.

4. Loosen the jam nut.

5. Loosen the spring adjustment screw, item #8 until

the spring, item #5, expands to a relaxed state. Some

spring tension will remain, see step #6. Remove the

adjustment screw.

6. Remove the three nuts, item #14, securing the upper

housing, item #1 to the valve body, item #2. This will

relieve the remaining spring force.

7. Lift off the upper housing, item #1, and lay on the

work bench. It may be necessary to loosen the upper

housing by tapping with a soft-faced hammer. Note:

Many of the components contained in the upper

housing may remain in place.

8. Remove the stem, item #10, the retainer, item #3, the

lower stem guide, item #7, the spring, item #5, and

the spring follower, item #6, from the bottom of the

upper housing.

9. Remove and discard the stem seal, item #22, from

the retainer, item #3, taking care not to mar seal

contact surfaces.

10. Reach inside the lower housing, item #2, and remove

the O-ring retainer, item #11, and the plug, item #12.

Push the plug out of the retainer.

11. Using a packing removal pick, remove the O-rings,

items #19 & 20 from the retainer taking care not to

mar the O-ring seating surfaces.