06

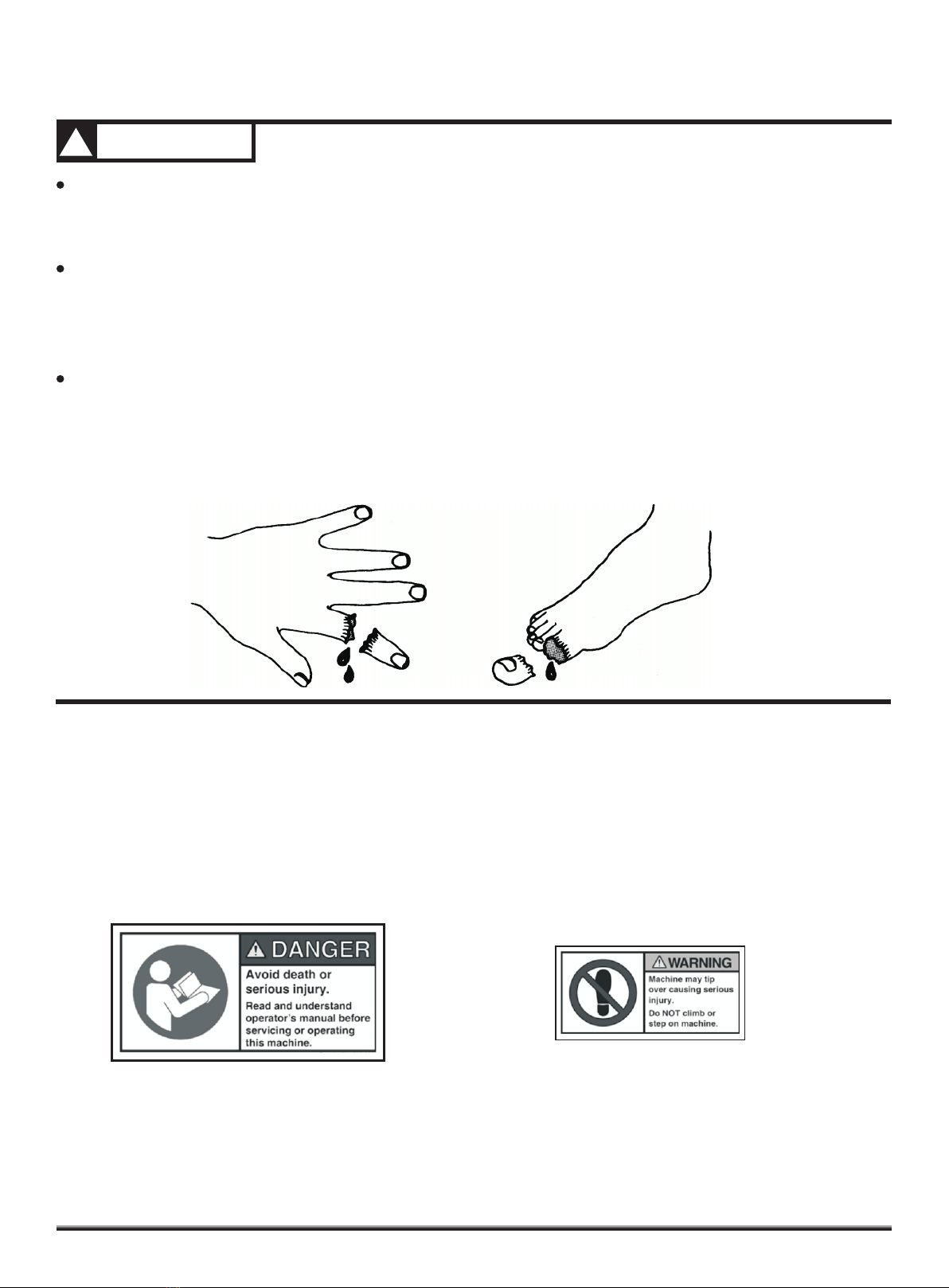

NEVER PLACE YOUR HANDS, FEET, OR ANY PART OF YOUR BODY IN THE CHIPPER HOPPER,

DISCHARGE OPENING, OR NEAR OR UNDER ANY MOVING PART WHILE THE MACHINE IS

RUNNING. KEEP AREA OF DISCHARGE CLEAR OF PEOPLE, ANIMALS, BUILDINGS, GLASS, OR

ANYTHING ELSE THAT WILL OBSTRUCT CLEAR DISCHARGE, CAUSE INJURY, OR DAMAGE. WIND

CAN ALSO CHANGE DISCHARGE DIRECTION, SO BE AWARE. IF IT BECOMES NECESSARY TO PUSH

MATERIAL INTO THE CHIPPER HOPPER, USE A SMALL DIAMETER STICK, NOT YOUR HANDS.

KEEP BYSTANDERS 100 FEET AWAY FROM YOURWORK AREA AT ALL TIMES. WOOD CHIPS EXIT

THE CHIPPER AT GREAT SPEEDS. TO BE SAFE, DONOT OPERATE THE MACHINE NEAR SMALL

CHILDREN OR PETS, AND NEVER ALLOW CHILDREN TO OPERATE THECHIPPER. STOP THE

ENGINE WHEN ANOTHER PERSON OR PET APPROACHES.

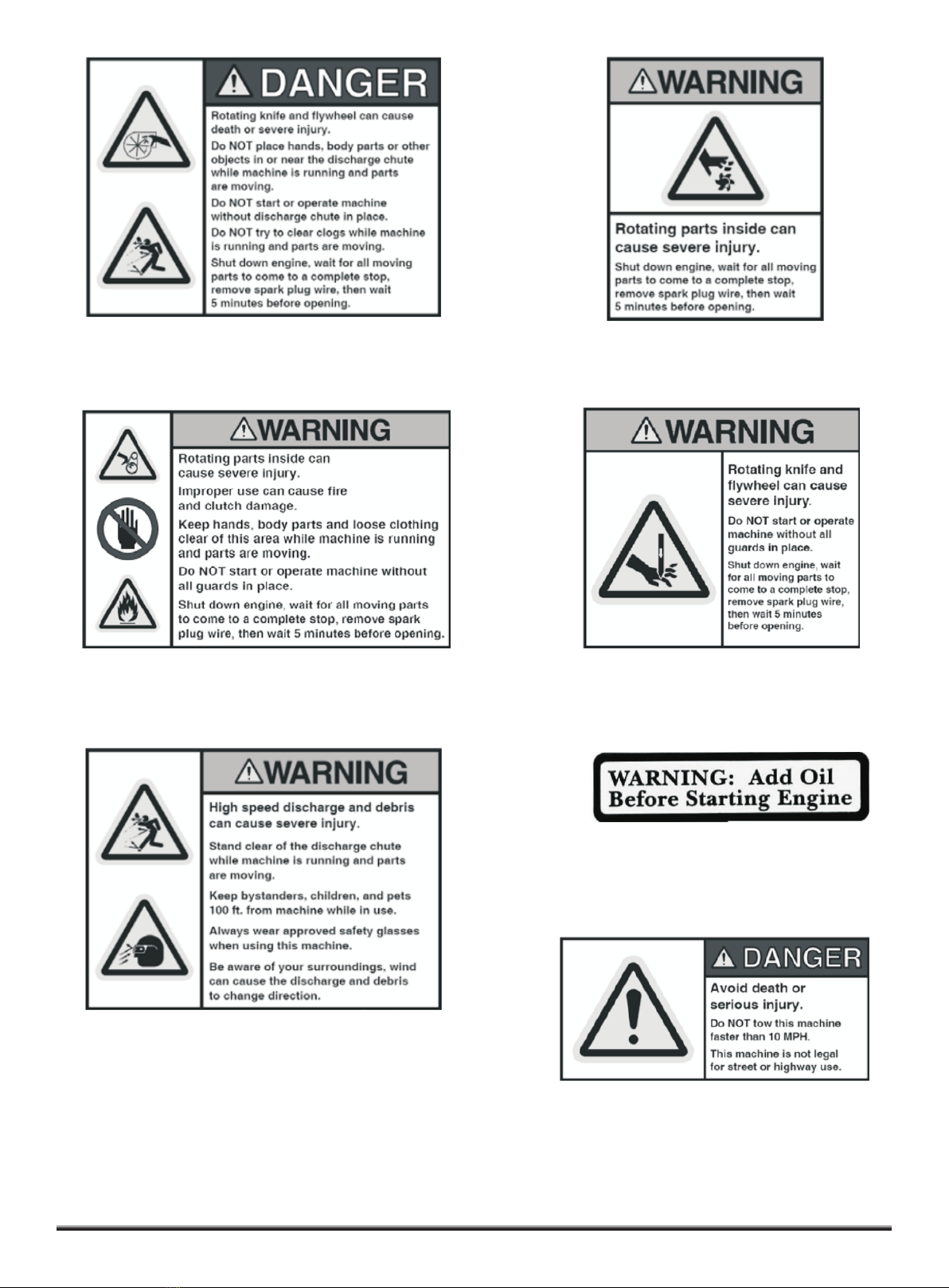

THE FLYWHEEL WILL STILL ROTATE FOR A WHILE AFTER THE ENGINE ISSHUT OFF. SHUT DOWN

THE ENGINE, WAIT FOR ALL MOVING PARTS TO COME TO A COMPLETE STOP, REMOVE SPARK

PLUG WIRE, THEN WAIT 5 MINUTES BEFORE MOVINGOR WORKING ON THE CHIPPER.

DO NOT OPERATE THE ENGINE WITH THE AIR CLEANER OR THE CARBURETOR AIR INTAKE COVER

REMOVED. REMOVAL OF SUCH PARTS COULD CREATE A FIRE HAZARD. DO NOT USE

FLAMMABLE SOLUTIONS TO CLEAN THE AIR FILTER.

!WARNING!

ALWAYS OPERATE THE MACHINE FROM THE OPERATOR ZONE . NEVER PASS OR STAND ON THE

DISCHARGE SIDE OF THE MACHINE WHEN THE ENGINE IS RUNNING OR THE FLYWHEEL IS

TURNING.

NEVER TRY TO PICK UP, MOVE, OR TRANSPORT THE MACHINE WHILE THE ENGINE IS RUNNING

OR THE FLYWHEEL IS TURNING. SHUT DOWN THE ENGINE, WAIT FOR ALL MOVING PARTS TO

COME TO A COMPLETE STOP (THE FLYWHEEL WILL CONTINUE ROTATING FOR A WHILE AFTER

THE ENGINE IS SHUT DOWN), DISCONNECT SPARK PLUG WIRE, KEEPING IT AWAY FROM THE

SPARK PLUG TO PREVENT ACCIDENTAL STARTING, THEN WAIT 5 MINUTES BEFORE MOVING.

THE MUFFLER AND ENGINE BECOME VERY HOT AND CAN CAUSE A SEVERE BURN; DO NOT TOUCH.

CLEAR THE AREA OF OBJECTS SUCH AS WIRE AND ROPE, ETC. INSERTING THESE OBJECTS INTO

THE CHIPPER HOPPER COULD DAMAGE THE FLYWHEEL AND/OR CAUSE INJURY.

NEVER, UNDER ANY CONDITIONS, REMOVE, BEND, CUT, FIT, WELD, OR OTHERWISE ALTER

STANDARD PARTS ON THE CHIPPER. THIS INCLUDES ALL SHIELDS AND GUARDS.

MODIFICATIONS TO YOUR MACHINE COULD CAUSE PERSONAL INJURIES AND PROPERTY

DAMAGE.

NEVER USE THE MACHINE WITHOUT ENSURING THAT ALL GUARDS AND SHIELDS ARE IN

PLACE,INCLUDING THE CHIPPER HOPPER,DISCHARGE CHUTE AND BLOWBACK SHIELD.